Glazing unit with frequency selective coating and method

A technology of embedded glass and coating, applied in the direction of chemical instruments and methods, antenna equipment with additional functions, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

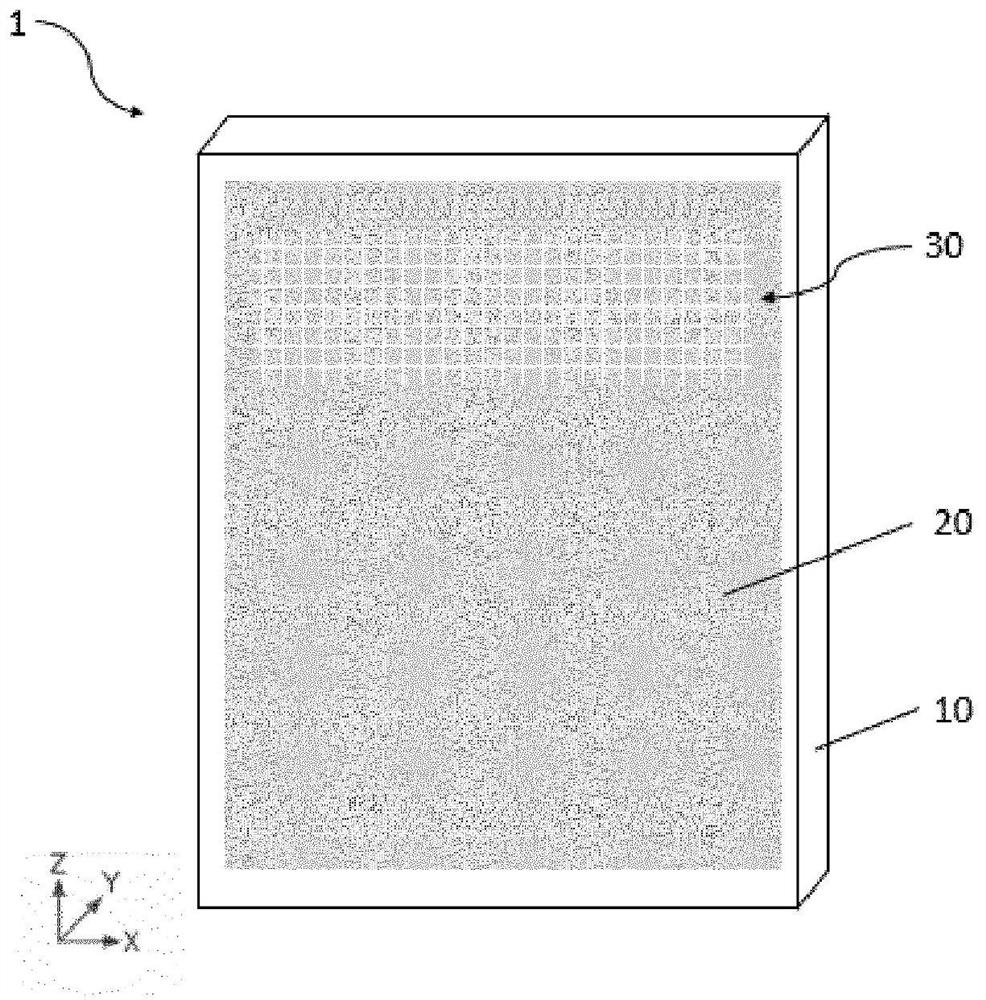

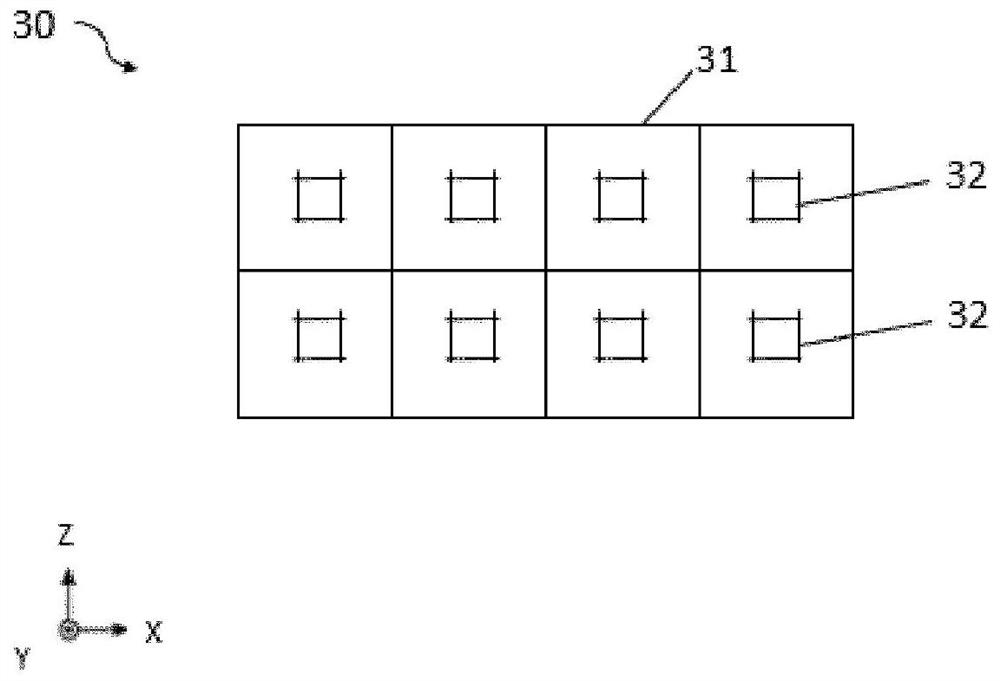

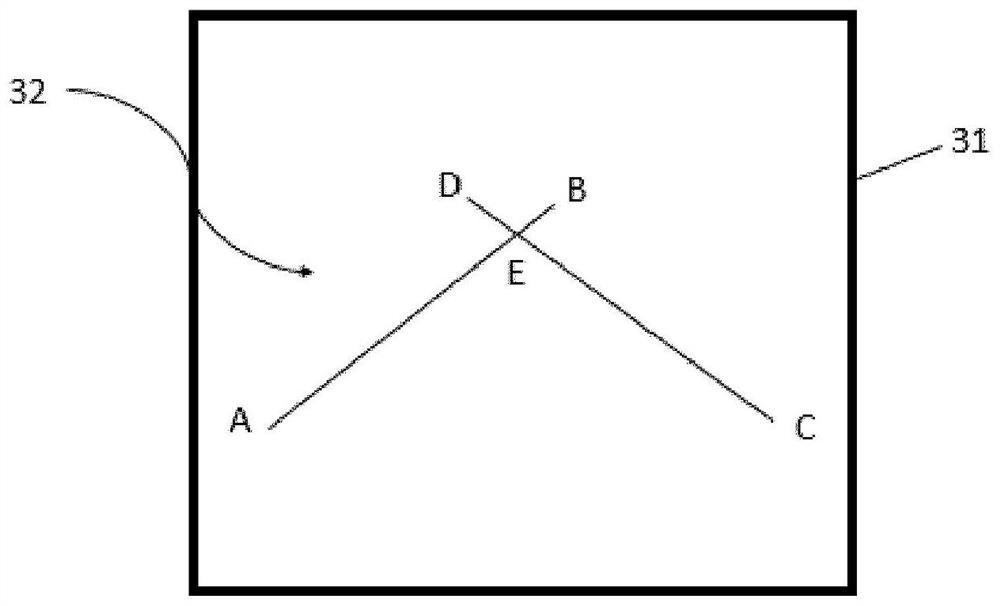

[0073] For better understanding, the scale of each component in the drawings may differ from the actual scale. In this specification, using a three-dimensional orthogonal coordinate system in three axis directions (X-axis direction, Y-axis direction, Z-axis direction), the width direction of the frequency-selective decoated portion is defined as the X direction, and the thickness direction is defined as is defined as the Y direction, and height is defined as the Z direction. The direction from the bottom to the top of the frequency-selective decoated portion was defined as the +Z-axis direction, and the opposite direction was defined as the -Z-axis direction. In the following description, the +Z-axis direction is referred to as upward and the -Z-axis direction may be referred to as downward.

[0074] refer to figure 1 , describes the first embodiment of the present invention.

[0075] Such as figure 1 As shown, the glazing unit 1 comprises a glass panel 10 with low reflect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com