Silybum marianum grease gel and preparation method thereof

A technology of oil gel and milk thistle oil, which is applied to the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve the problems that are difficult to control and affect the gel ability, so as to enhance the antioxidant capacity, Extended shelf life, cholesterol and triglyceride lowering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

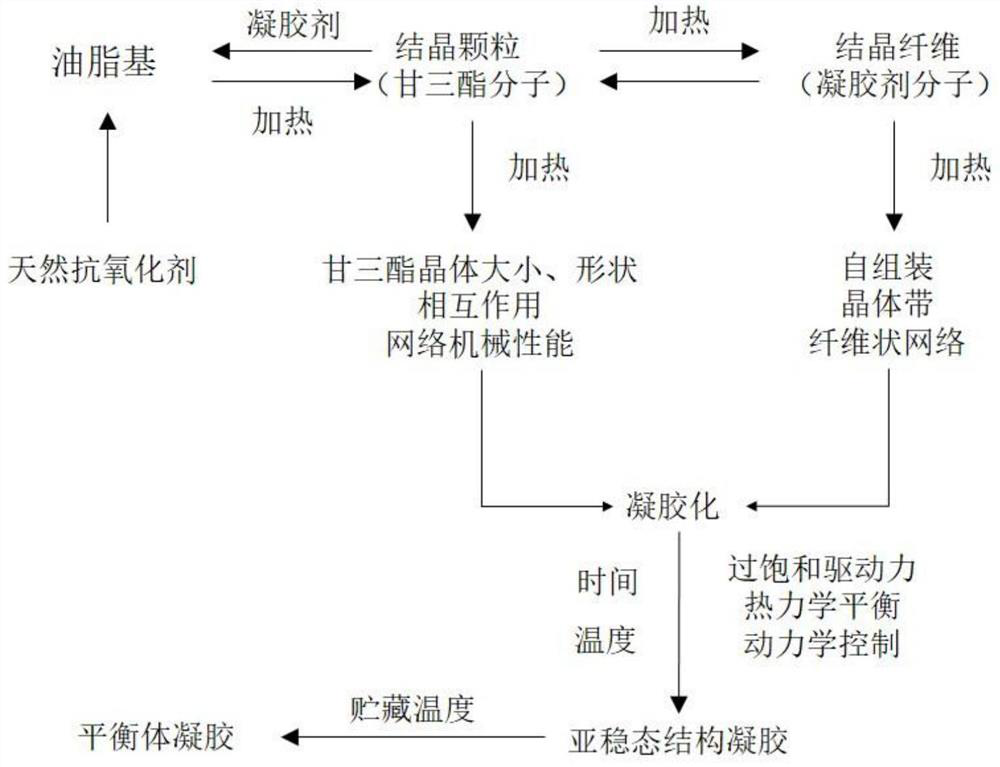

[0029] see figure 1 , the preparation process of the grease gel of the present invention is carried out as follows:

[0030] Step 1. Dissolve 150mg of blueberry peel extract anthocyanins in 0.1mL of food-grade absolute ethanol, and add 350g of milk thistle oil to the beaker, and mix well;

[0031] Step 2, adding 42.4g of β-sitosterol and 10g of phospholipid with a purity of 75% to the beaker, and fully mixing;

[0032] Step 3. Start the constant temperature heating magnetic stirrer, and preheat the hot water bath to 100°C;

[0033] Step 4. Place the beaker in a water bath, adjust the speed of the constant temperature heating magnetic stirrer to 600r / min, and heat and stir for 35 minutes;

[0034] Step 5. After heating and stirring, transfer to a storage bottle;

[0035] Step 6. Quickly transfer the storage bottle to a 5°C refrigerator until it is completely cooled to obtain the milk thistle oil gel.

Embodiment 2

[0037] see figure 1 , the preparation process of the grease gel of the present invention is carried out as follows:

[0038] Step 1. Dissolve 170mg of blueberry peel extract anthocyanins in 0.2mL of food-grade absolute ethanol, and add 450g of milk thistle oil into the beaker, and mix well;

[0039] Step 2, add 54.6g of β-sitosterol and 15g of phospholipids with a purity of 75% to the beaker, and mix well;

[0040] Step 3. Start the constant temperature heating magnetic stirrer, and preheat the hot water bath to 100°C;

[0041] Step 4. Place the beaker in a water bath, adjust the speed of the constant temperature heating magnetic stirrer to 800r / min, and heat and stir for 35 minutes;

[0042] Step 5. After heating and stirring, transfer to a storage bottle;

[0043] Step 6. Quickly transfer the storage bottle to a 5°C refrigerator until it is completely cooled to obtain the milk thistle oil gel.

Embodiment 3

[0045] see figure 1 , the preparation process of the grease gel of the present invention is carried out as follows:

[0046] Step 1. Dissolve 160mg of blueberry peel extract anthocyanins in 0.16mL food-grade absolute ethanol, add 400g of milk thistle oil to the beaker, and mix well;

[0047] Step 2, adding 48.5g of β-sitosterol and 12.8g of phospholipids with a purity of 75% to the beaker, fully mixed;

[0048] Step 3. Start the constant temperature heating magnetic stirrer, and preheat the hot water bath to 100°C;

[0049] Step 4. Place the beaker in a water bath, adjust the speed of the constant temperature heating magnetic stirrer to 700r / min, and heat and stir for 35 minutes;

[0050] Step 5. After heating and stirring, transfer to a storage bottle;

[0051] Step 6. Quickly transfer the storage bottle to a 5°C refrigerator until it is completely cooled to obtain the milk thistle oil gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com