Teabag

A kind of technology for making tea in bag, which is applied in the field of tea bag, which can solve the problems of moth-eaten, easy mildew of bag tea, storage and validity period limitation, etc., so as to prevent arteriosclerosis, enhance absorption and utilization, and inhibit thrombus the formation of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0031] Teabags include inner filter bags and teabag raw materials, and the processing of teabag raw materials is as follows:

[0032] Treatment of earthworm and natto: take 300g of earthworm and 400g of natto respectively.

[0033] Since earthworm and natto both contain water-soluble ingredients such as protein and amino acid, they are mixed together with water as a solvent for extraction, and the active ingredients are extracted according to different soaking time, water amount, and decoction time.

[0034] a. Soaking time, amount of water added, decocting time

[0035] Table 1: Orthogonal factor level table

[0036]

Soaking time (min)

Amount of water added (times)

Cooking time (min)

1

20

8

60

2

40

10

90

3

60

12

120

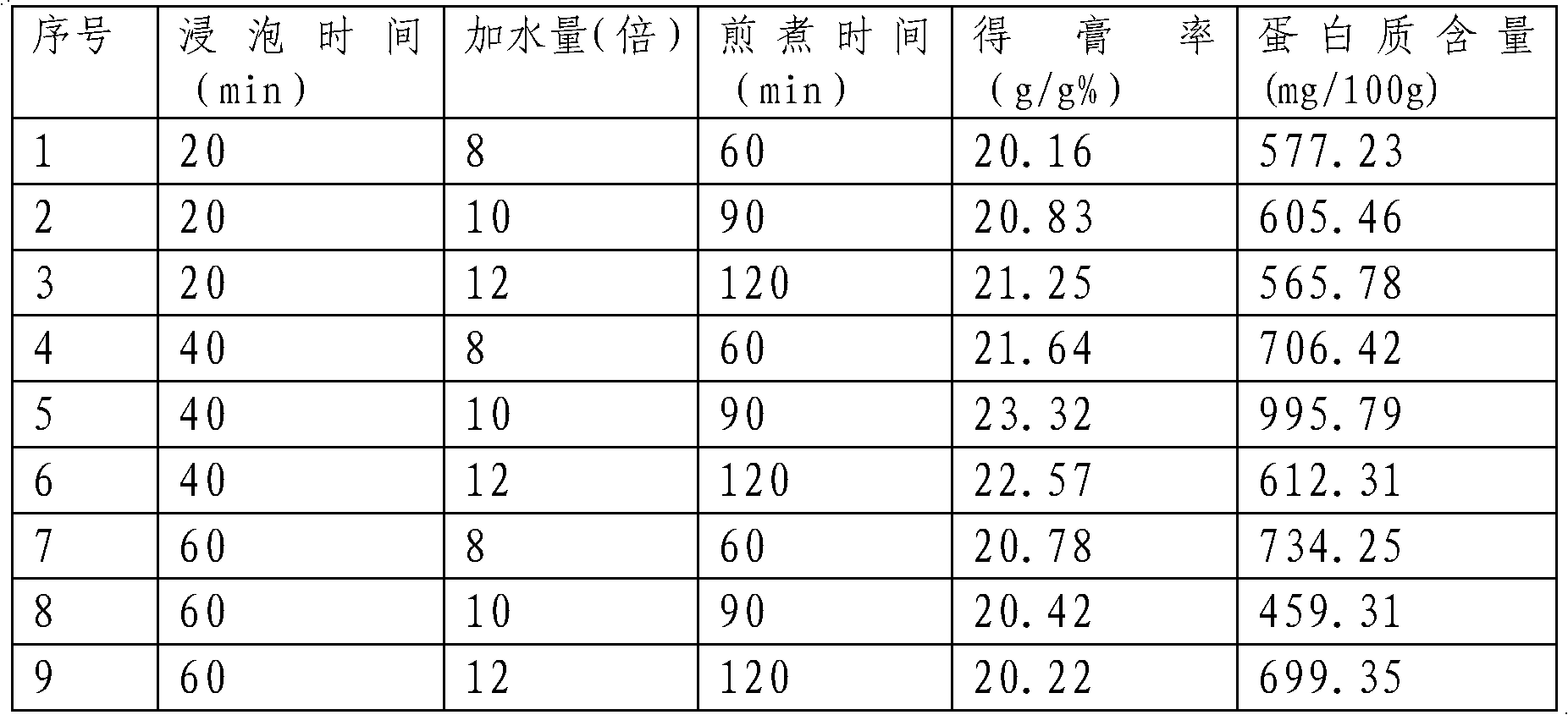

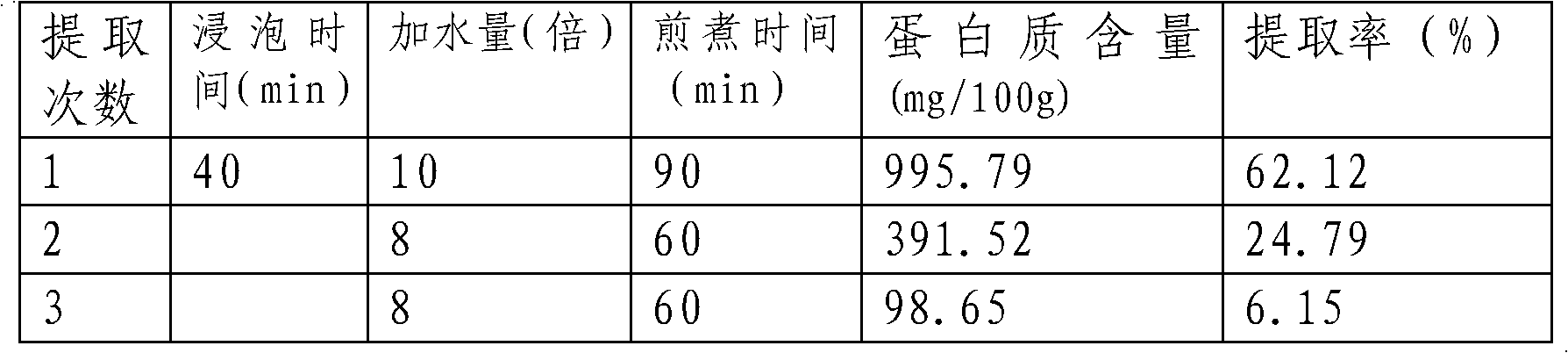

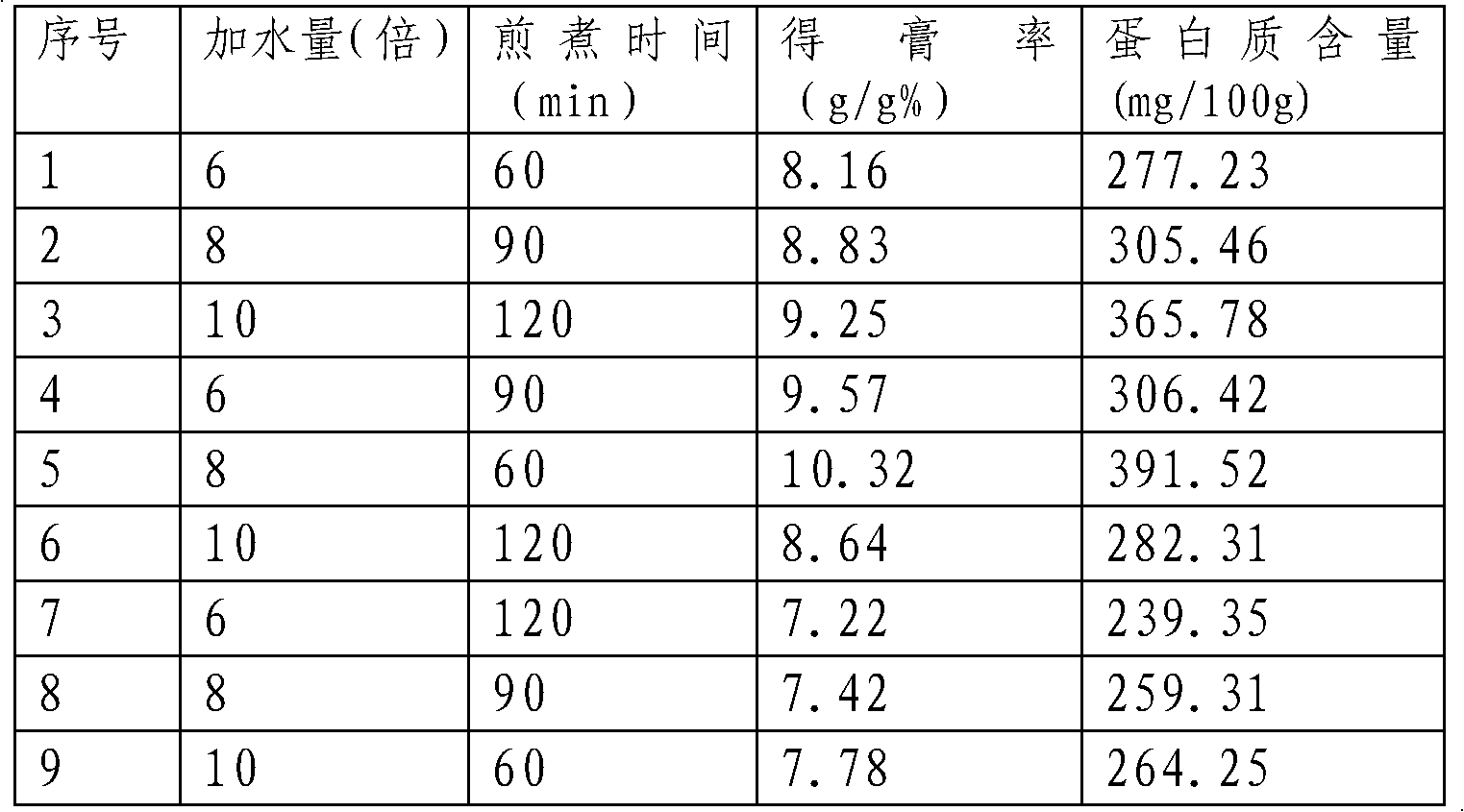

[0037] Table 2: Yield and protein content of Examples 1-9

[0038]

[0039] According to the above examples, the soaking time is 40 minutes, the amount o...

Embodiment 10

[0067] The Cordyceps militaris and licorice residue extracted in the above-mentioned Examples 1-9 were dried, and after drying, they were pulverized into fine powder with a 80-100 mesh sieve.

[0068] The extract with the best relative density extracted from the above two extracts (that is, the relative density is 1.32) is fully mixed with the fine powder, and dried at a temperature not exceeding 60-80°C to obtain a dry product.

[0069] Determination of this process: Since the extract is dried alone, the drying time will be increased, and the increase of the drying time will cause some damage to the active ingredients, so the slag after the extraction of Cordyceps militaris and licorice is dried and pulverized into fine powder, and mixed into the extract. To absorb moisture and reduce drying time.

[0070] Grind the dried product into fine powder with 80-100 mesh sieve, then use 75% alcohol instead of water as excipient for granulation, dry at 60-80°C, and then divide into pa...

Embodiment 11

[0077] The Cordyceps militaris and licorice residue extracted in the above-mentioned Examples 1-9 were dried, and after drying, they were pulverized into fine powder with a 80-100 mesh sieve.

[0078] It is 1.31 that the extractum of relative density is extracted from two kinds of extracts, and the extractant of relative density is 1.31 and Cordyceps militaris and Radix Glycyrrhiza extract are fully mixed with fine powder, and in no more than 60- Dry at a temperature of 80°C to obtain a dry product.

[0079] Determination of this process: Since the extract is dried alone, the drying time will be increased, and the increase of the drying time will cause some damage to the active ingredients, so the slag after the extraction of Cordyceps militaris and licorice is dried and pulverized into fine powder, and mixed into the extract. To absorb moisture and reduce drying time.

[0080] Grind the dried product into fine powder with 80-100 mesh sieve, then use 75% alcohol instead of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com