Fault diagnosis method and system for hot air adjusting baffle

A technology for adjusting baffles and fault diagnosis, which is applied in grain processing and other directions, and can solve problems such as stuck and sudden closing of hot air adjustment baffles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

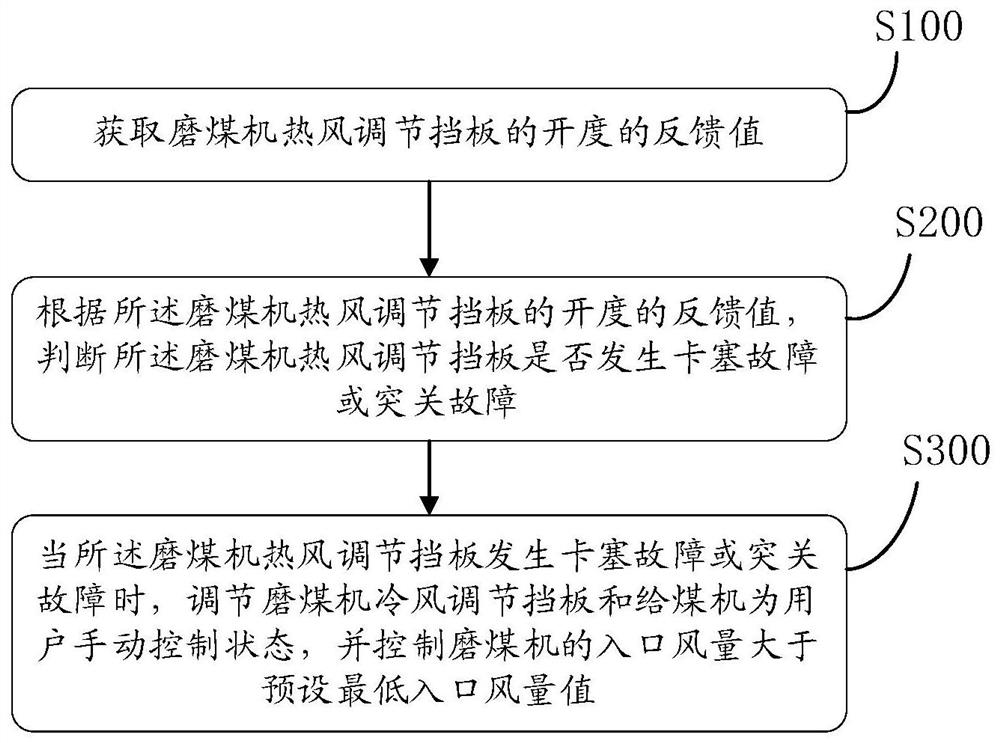

[0057] like figure 1 As shown, a method for diagnosing a fault of a hot air regulating baffle according to an embodiment of the present invention includes the following steps:

[0058] S100. Obtain the feedback value of the opening of the hot air regulating baffle of the coal mill;

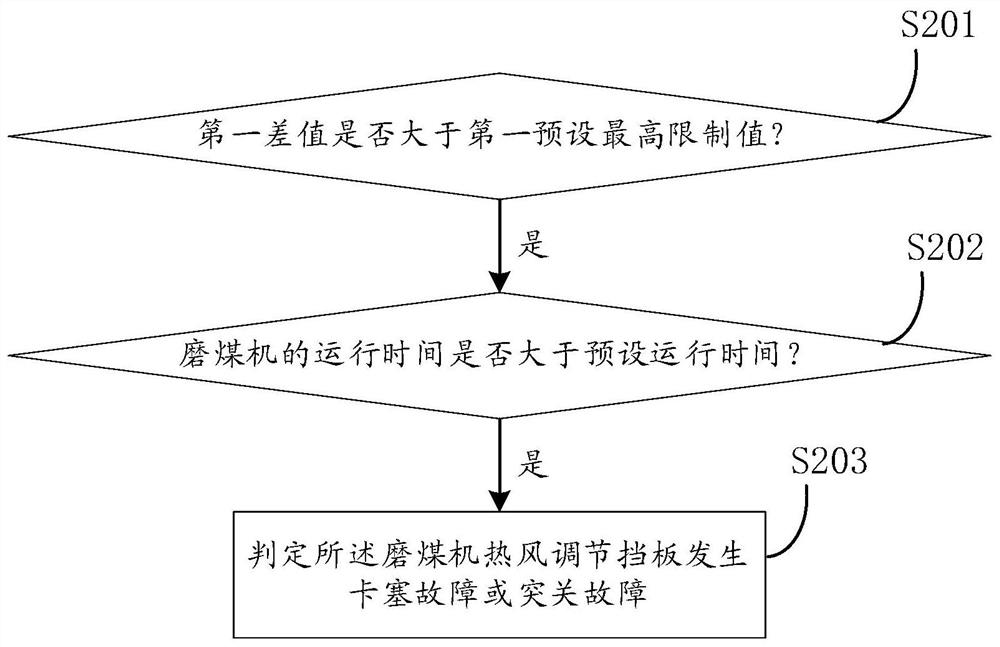

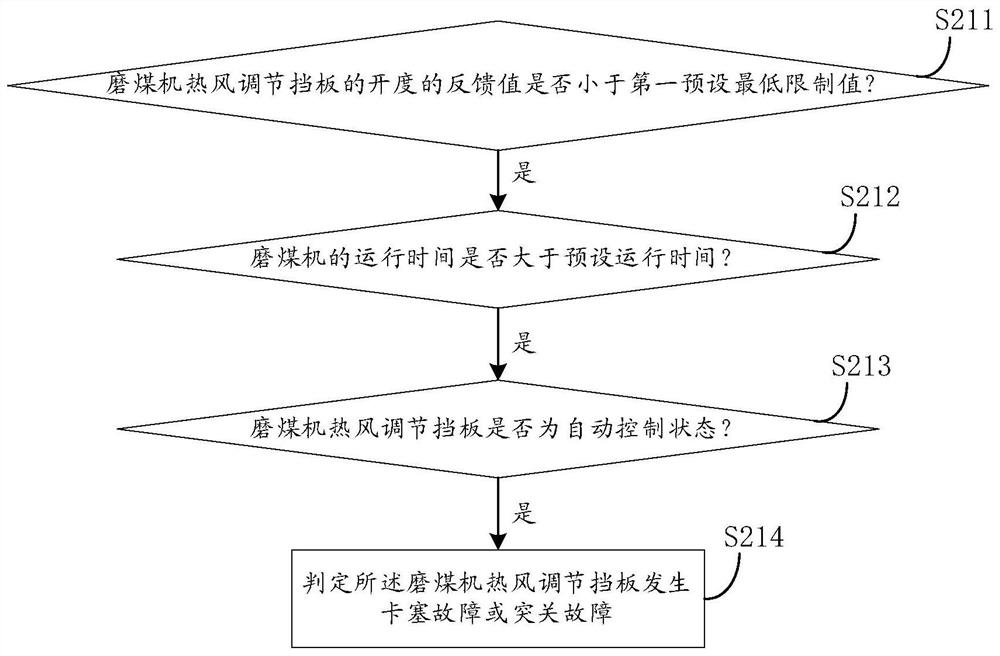

[0059] S200. According to the feedback value of the opening degree of the hot air regulating baffle of the coal mill, judge whether the hot air regulating baffle of the coal mill is stuck or suddenly closed.

[0060] By obtaining the feedback value of the opening degree of the hot air regulating baffle of the coal mill, the situation of the hot air regulating baffle can be known in time, so as to facilitate the diagnosis of the hot air regulating baffle through the processing of the feedback value of the opening degree of the hot air regulating baffle Whether there is a jamming fault or a sudden closing fault on the board, so as to give the staff an effective early warning, and then avoid major a...

Embodiment 2

[0112] like Figure 4 As shown, a fault diagnosis system for a hot air regulating baffle according to an embodiment of the present invention includes a controller 100;

[0113] The controller 100 collects the feedback value of the opening degree of the hot air regulating baffle of the coal mill through the potentiometer 103 installed on the hot air regulating baffle 200 of the coal mill;

[0114] The controller 100 judges whether the coal mill hot air regulating baffle 200 is jammed or suddenly closed according to the feedback value of the opening of the coal mill hot air regulating baffle 200 .

[0115] By obtaining the feedback value of the opening degree of the hot air regulating baffle of the coal mill, the controller 100 can know the situation of the hot air regulating baffle in time, so as to facilitate diagnosis by processing the feedback value of the opening degree of the hot air regulating baffle Whether the hot air regulating baffle has a jamming fault or a sudden c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com