Method and system for backfire monitoring

A technology of ignition energy and ignition advance angle, applied in charging system, automatic control, automatic control and other directions, can solve problems such as engine damage and insufficient power of natural gas engine, and achieve the effect of avoiding fault misjudgment and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

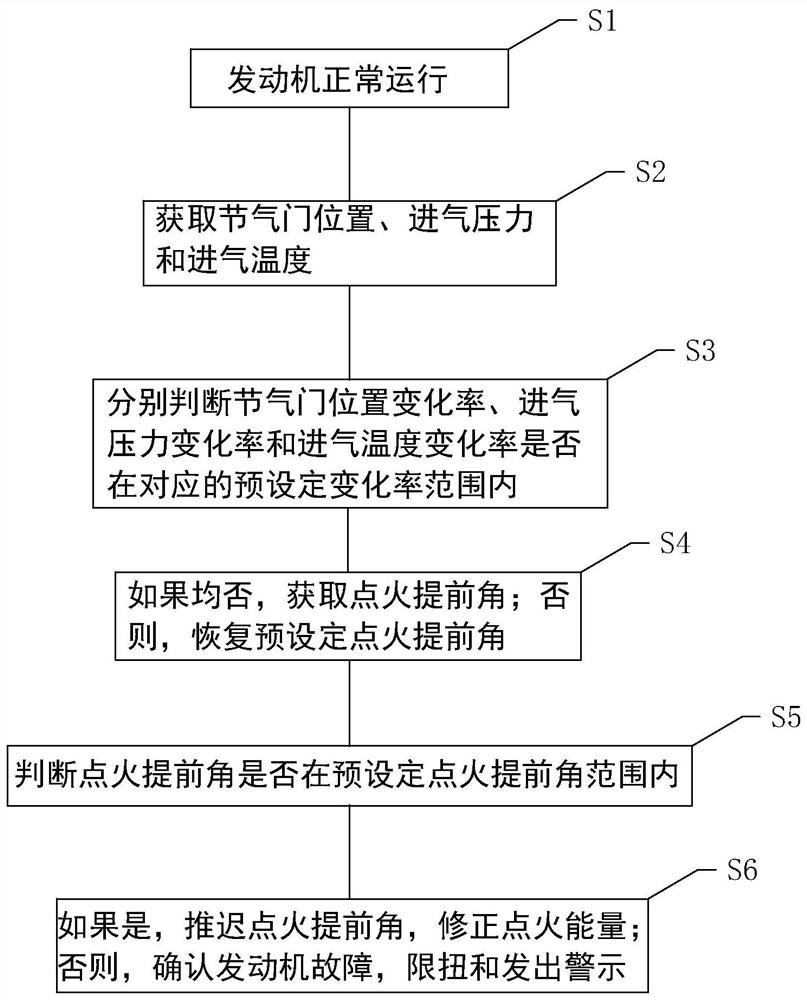

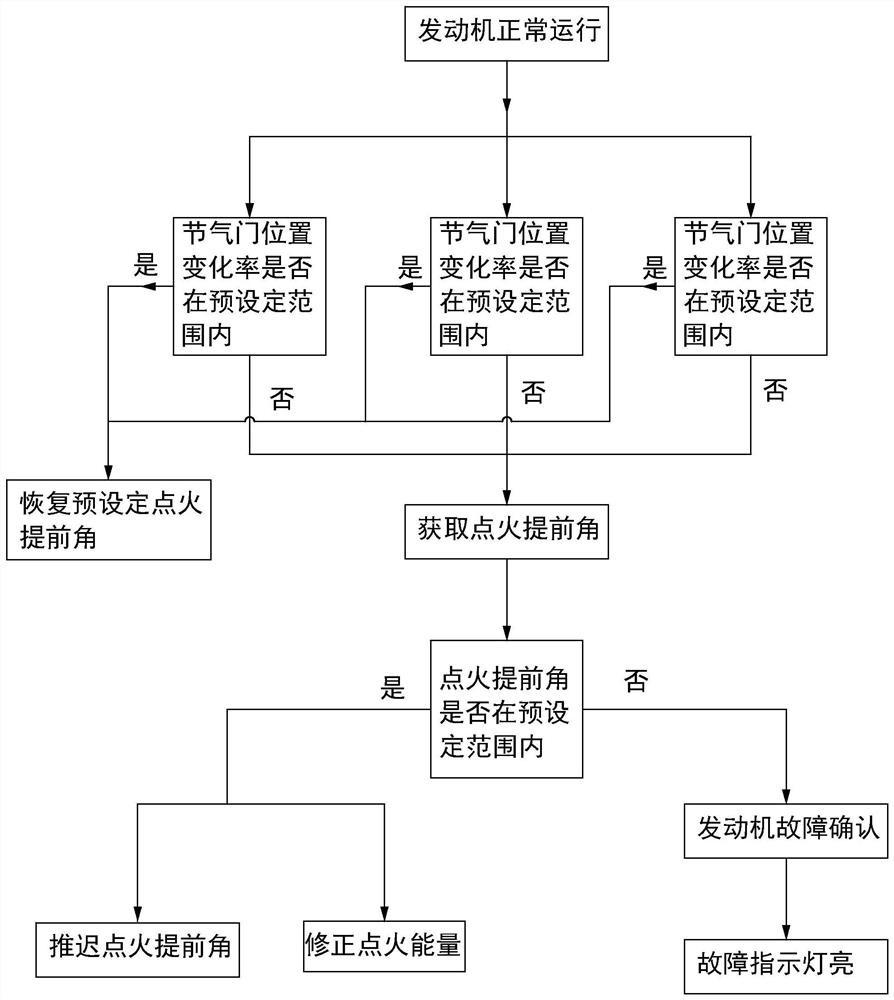

[0034] like figure 1 and figure 2 As shown, a method for tempering monitoring includes the following steps:

[0035] Step S0, judging the validity of the sensor; the purpose of judging the validity of the sensor is to collect accurate data so as to accurately monitor the tempering and avoid misjudgment and untimely judgment. The sensor validity judgment is to use other sensors on the car, combined with ambient temperature, humidity, pressure, etc., to test the validity of the sensor when the car is parked. If the sensor used in the present invention is consistent with the environmental parameters collected by other sensors on the vehicle, or if the sensor is powered on, it indicates that the sensor is valid.

[0036] Step S1 , the engine is running normally; whether it is running normally is judged by the engine speed and load.

[0037] Step S2, acquiring throttle position, intake pressure and intake temperature;

[0038] Step S3, respectively judging whether the rate of ...

Embodiment 2

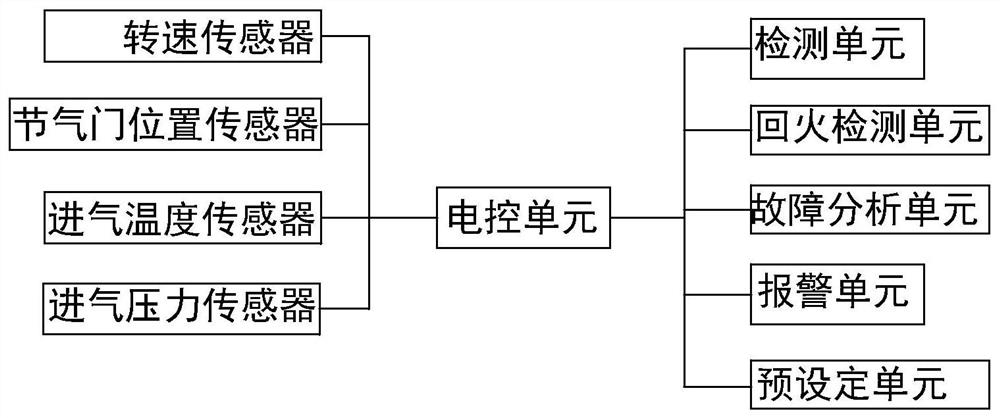

[0054] like image 3 As shown, a tempering monitoring system includes an electronic control unit, a detection unit electrically connected to the electric control unit, a tempering detection unit and a fault analysis unit. The detection unit is used to obtain the throttle position, intake air pressure and intake air temperature. The detection unit includes a speed sensor, a throttle position sensor, an intake air temperature sensor and an intake air pressure sensor; the tempering detection unit is used to judge the throttle valve respectively. Whether the rate of change of position, the rate of change of intake pressure and the rate of change of intake air temperature are within the corresponding preset range of rate of change, if none of them are within the range, a backfire occurs, otherwise no backfire occurs; the fault analysis unit is used to obtain Ignition advance angle, to judge whether the ignition advance angle is within the preset ignition advance angle range; if yes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com