Fastening mechanism for aluminium alloy lightweight machining equipment and using method of fastening mechanism

A technology of processing equipment and fastening mechanism, which is applied in the field of aluminum alloy lightweight processing equipment, can solve the problems that the precision of processed parts cannot meet the production requirements, the tightening extrusion force is weakened, and it is easy to move, so as to achieve good processing parts Effects of movement, prevention of workpiece movement, and reduction of operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

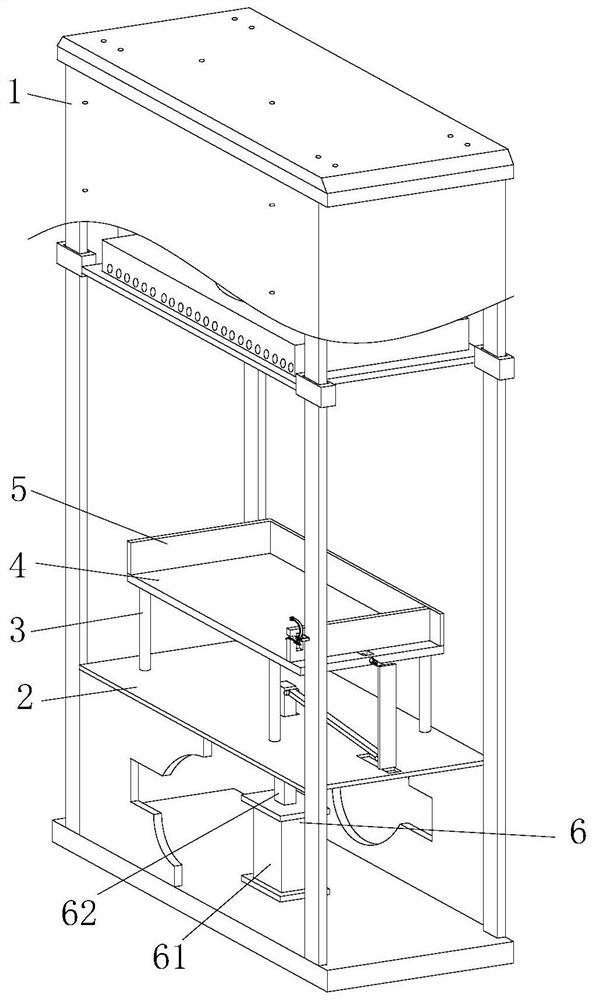

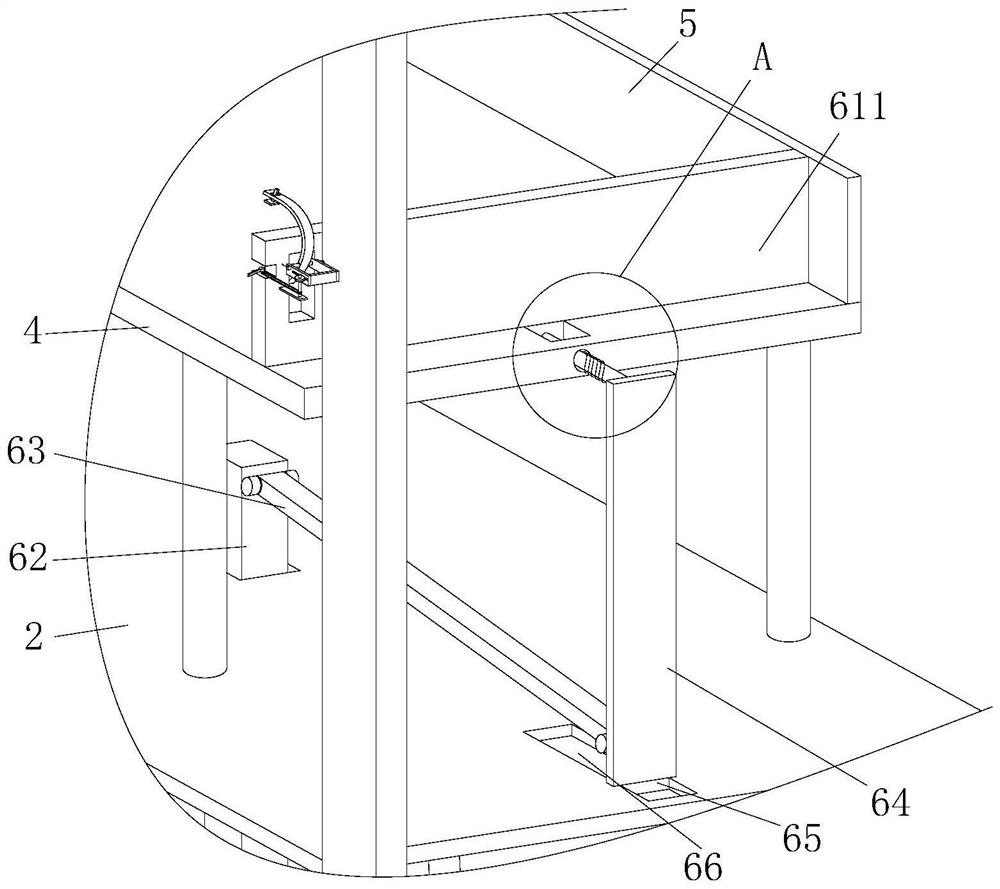

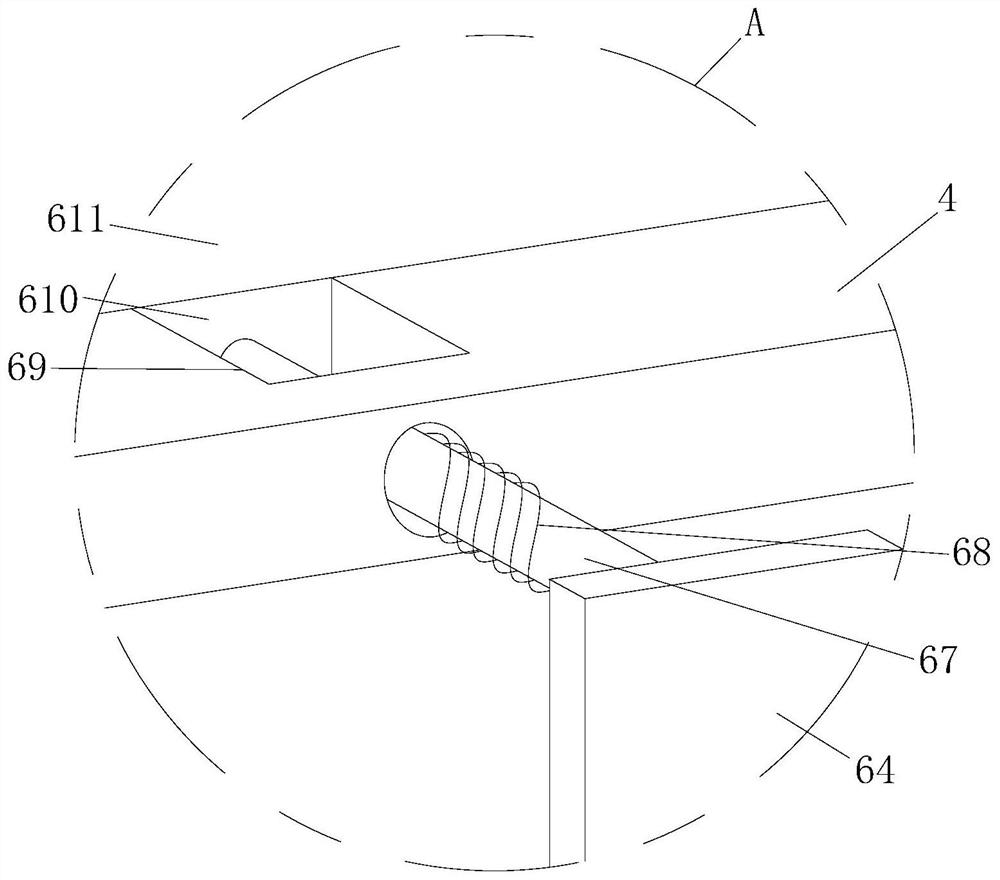

[0034] Attached below Figure 1-5 The present invention is further described with embodiment:

[0035] A fastening mechanism for aluminum alloy lightweight processing equipment, comprising an equipment bracket 1 and a supporting plate 2, the supporting plate 2 is fixedly arranged inside the equipment bracket 1, and four supports are arranged in a matrix on the upper end surface of the supporting plate 2 rod 3, and the upper end of the support rod 3 is fixedly connected to the lower end surface of the placing plate 4, and the upper end of the placing plate 4 is fixedly connected with an L-shaped protective plate 5. In the present invention, by improving the existing aluminum alloy lightweight processing equipment, the fastening The structure of the mechanism, the improved fastening mechanism for aluminum alloy lightweight processing equipment can realize the clamping of the workpiece from the front and the resistance from the top, so that in the actual work process, it can prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com