New energy tensioner and control method thereof

A tension machine and new energy technology, applied in the field of new energy tension machine and its control, can solve the problems of high engine maintenance cost, high equipment noise, pollution of the environment, etc., and achieve the effects of flexible response, low noise and fast response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

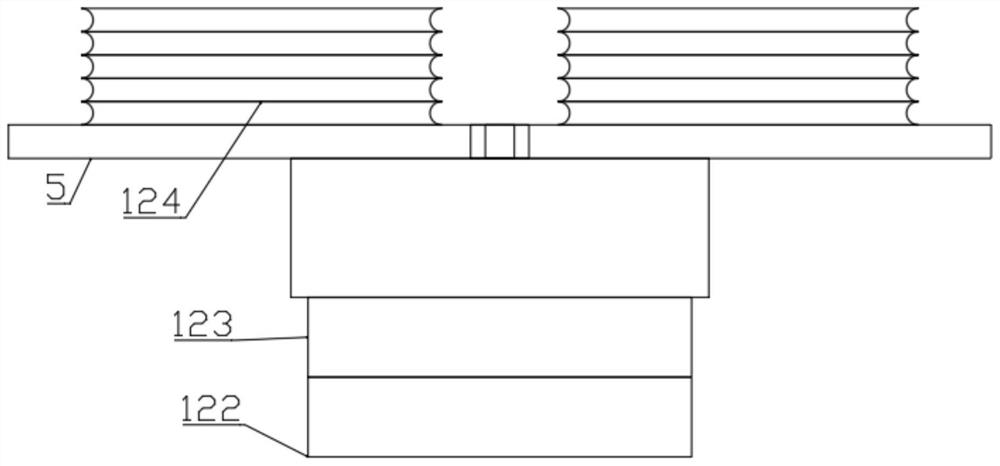

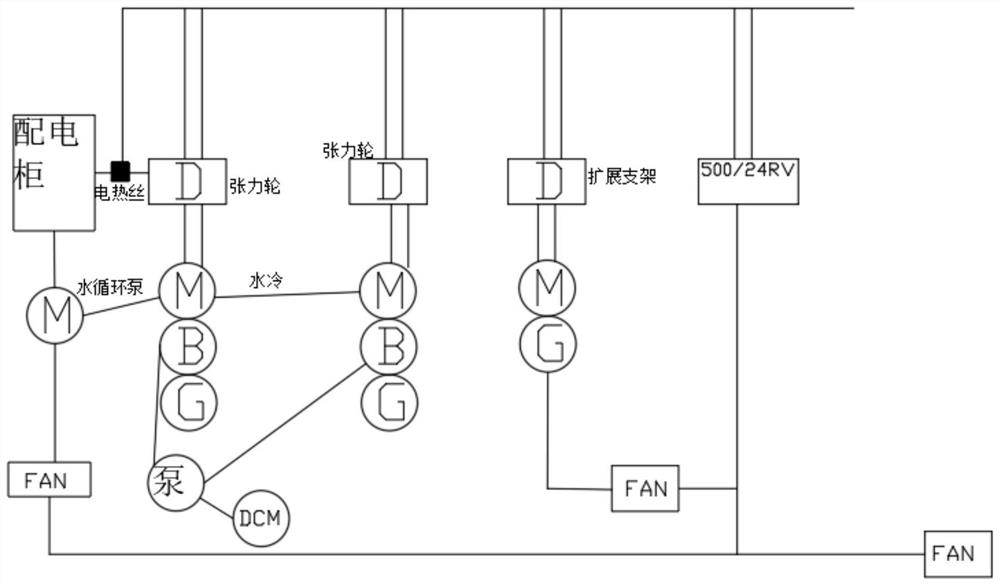

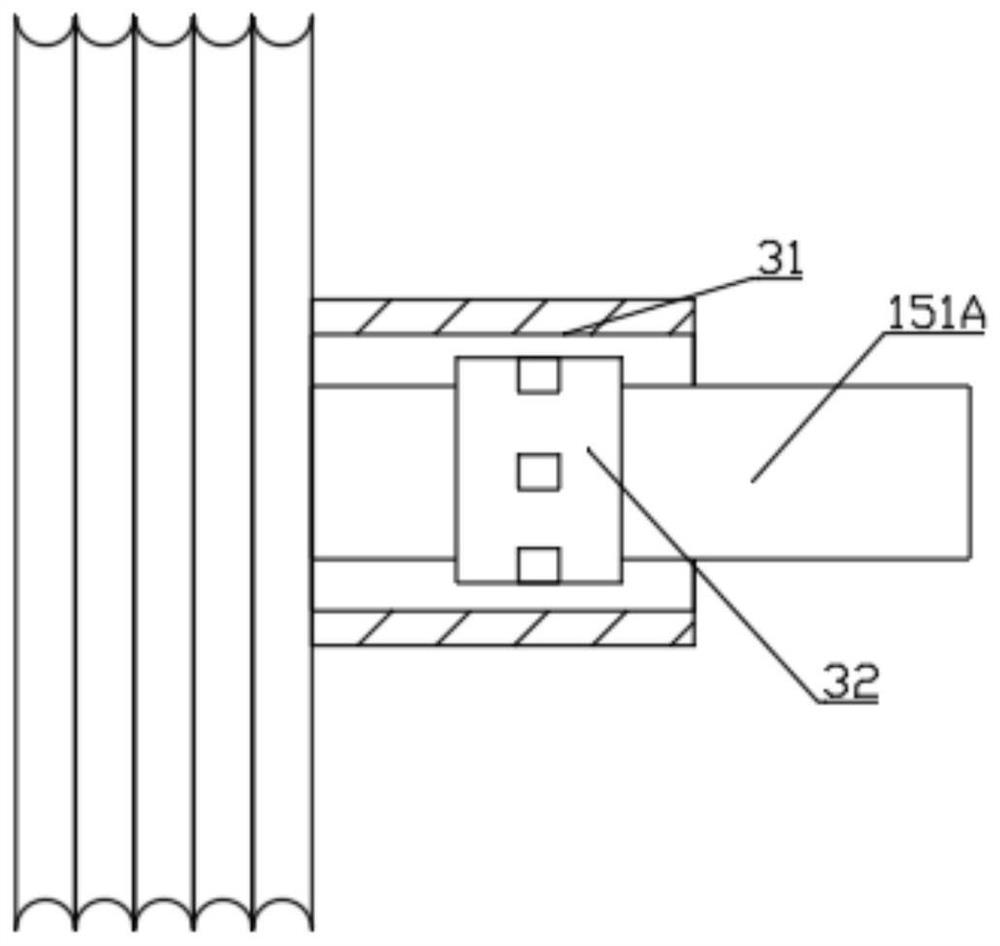

[0034] Such as Figure 1-5 As shown, a new energy tension machine includes a tension machine body 1 and a connecting circuit 2. The tension machine body 1 consists of an energy storage module 11, a first drive unit 12, a second drive unit 13, an auxiliary structural unit 14 and an energy recovery module. 15, the first drive unit 12 and the second drive unit 13 have the same structure, the first drive unit 12 includes a frequency converter 121, a motor 122 electrically connected to the frequency converter 121 through wires, a reducer 123 connected to the motor 122, The gear set 5 connected to the speed reducer 123 and the tension pulley 124 driven by the gear set 5, the energy recovery module includes a transformer 153 and a current stabilizer, the transformer 153 is electrically connected to the energy storage module 11 through wires, and the motor 122 is driven by the tension pulley 124. Convert external energy into usable energy under rotation.

[0035] Such as figure 1 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com