Concrete encapsulation method for large-diameter pipeline

A technology for large-diameter pipes and concrete, which is applied in sewer pipe systems, pipe laying and maintenance, and waterway systems. It can solve problems such as lateral movement of pipes, reduce lateral movement, improve firmness, improve production efficiency and The effect of making convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

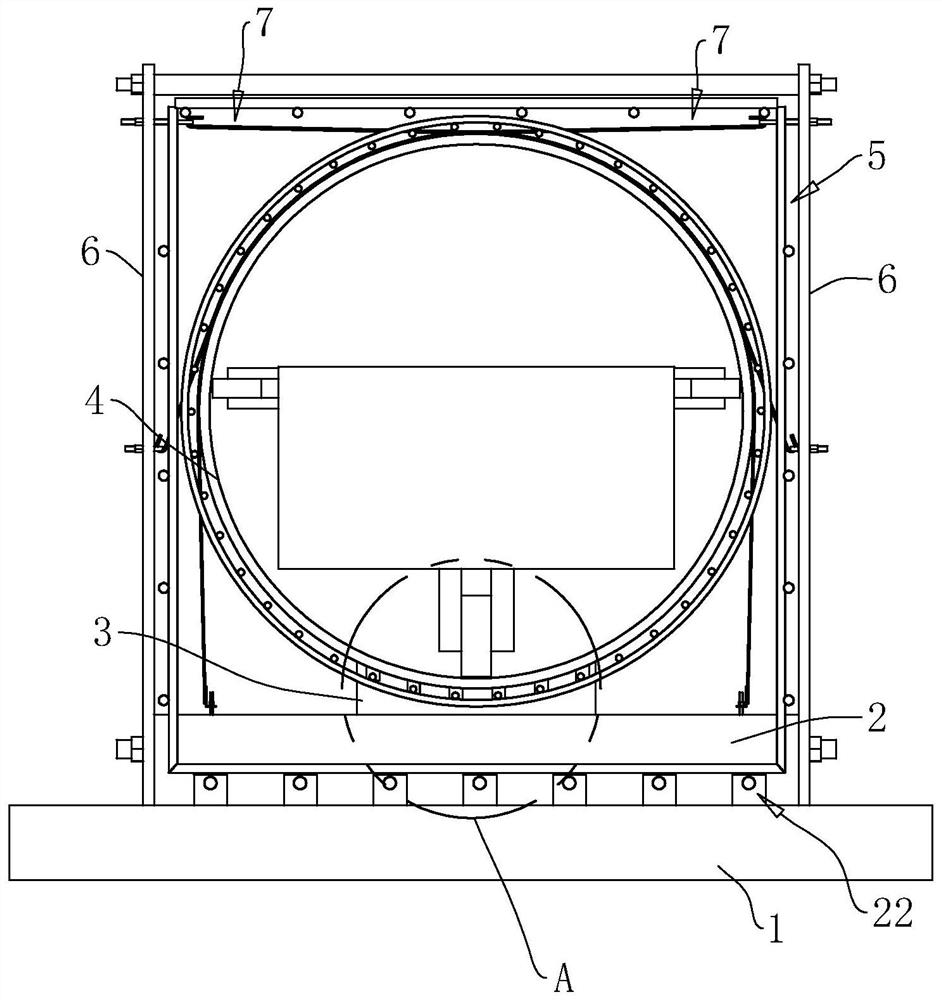

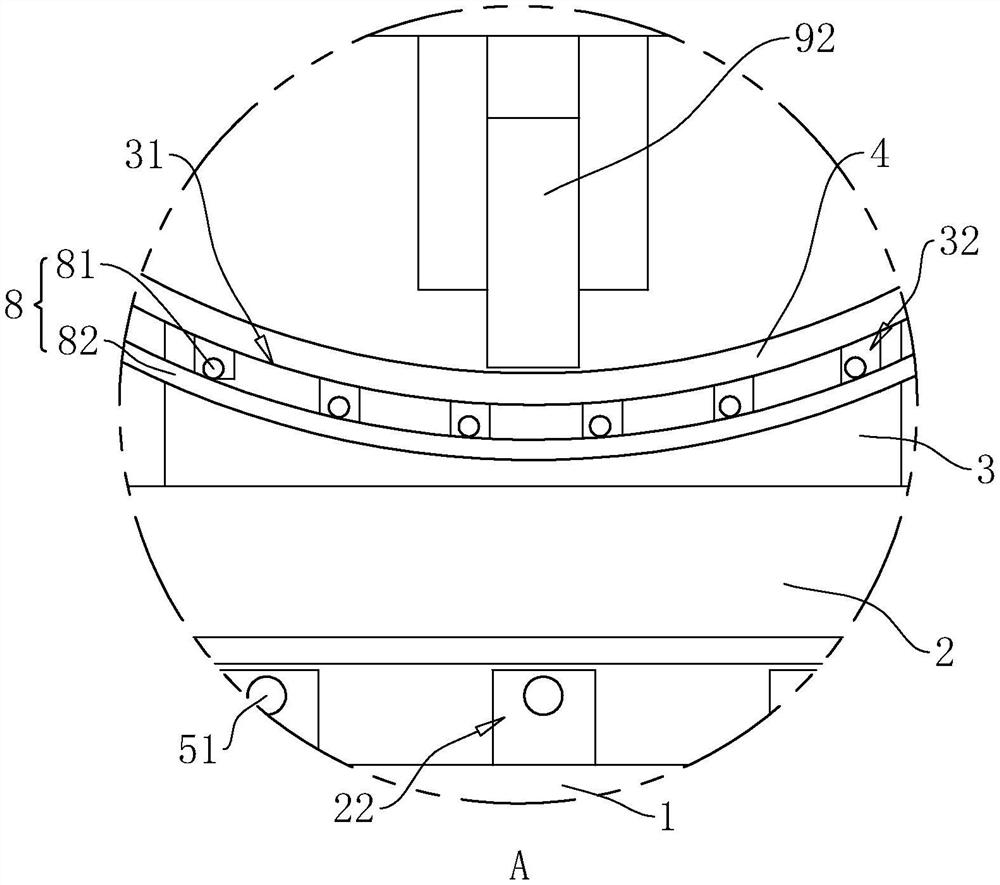

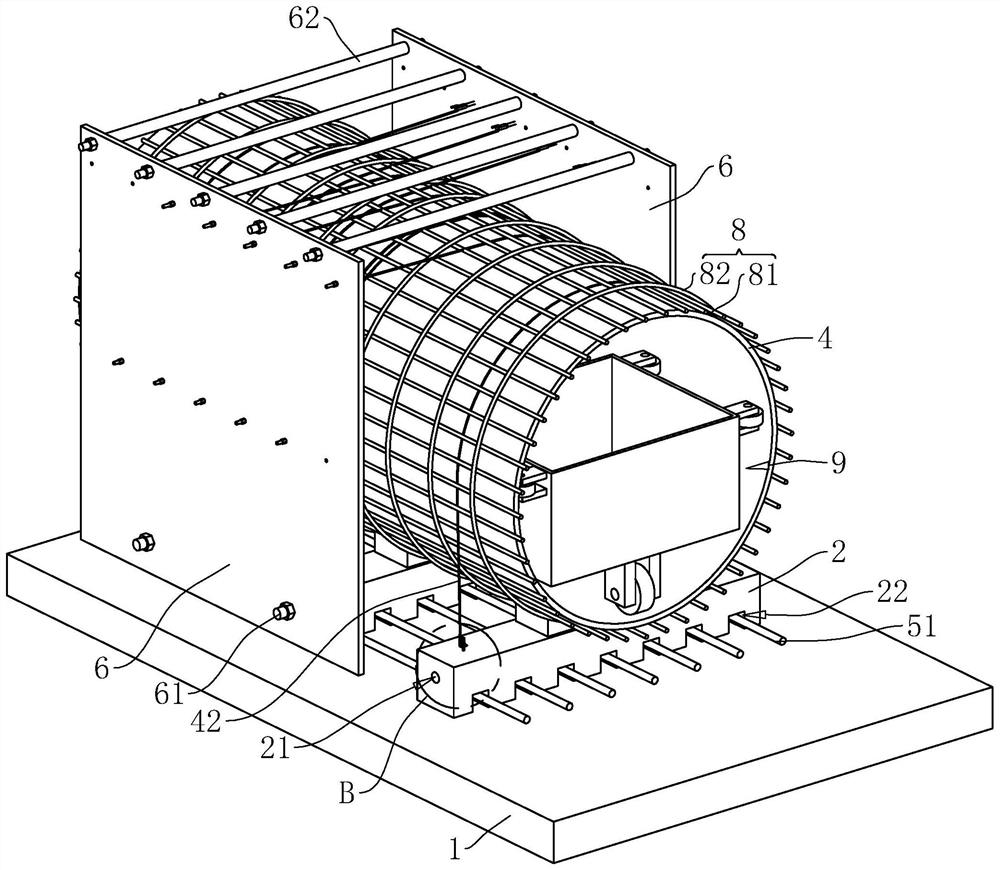

[0038] The following is attached Figure 1-6 The application is described in further detail.

[0039] The embodiment of the present application discloses a large-diameter pipeline concrete encapsulation method. refer to figure 1 , including laying a layer of plain concrete layer 1 at the bottom of the laying trench first, the plain concrete layer 1 is 2-3cm, and the upper surface of the plain concrete layer 1 is leveled. After the plain concrete layer 1 reaches the design hardness, the plain concrete layer The upper surface of 1 is provided with a prefabricated base 2, and the middle position of the upper surface of the prefabricated base 2 is integrated with the prefabricated base 2 to form an arc-shaped seat 3, on which a pipe 4 is placed, and a plurality of prefabricated bases are evenly laid in the length direction of the pipe 4 2. Set the prefabricated bases 2 at intervals, install the steel bar components 5, and install formwork 6 on both sides of the pipeline 4, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com