Forming device and method of weighing alarm assembly for intelligent automobile logistics

A molding device, automobile technology, applied in the detailed information of weighing equipment, measuring device, weighing and other directions, can solve the problems of difficult to detect the position change of goods, single structure and function, poor sensitivity, etc., to facilitate maintenance work. , high sensitivity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

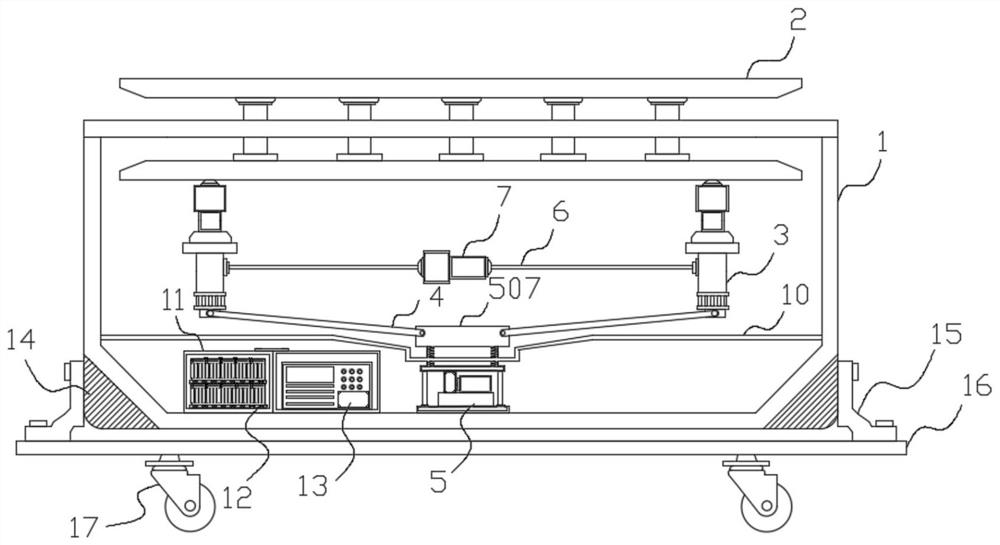

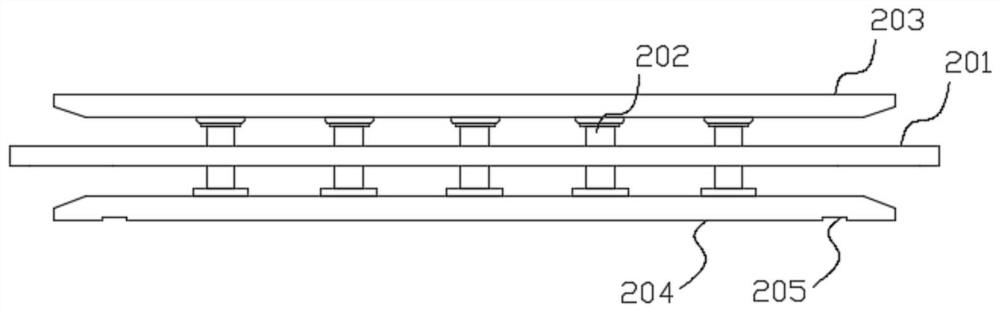

[0038] S1, the surface around the bottom of the PVC plastic shell 1 is fixedly connected with the mounting plate 16 through screw fit, so as to ensure that the shell 1 part can cooperate with the bottom mounting plate to communicate with the universal brake wheel 17 to move;

[0039] S2. Install the storage battery 12 and the alarm device main body 13 on the bottom surface of the casing 1 in sequence, and install the second weighing mechanism 5 at the center part of the casing 1, so that the connecting spring 506 part of the mechanism is fixed to the connecting seat 507;

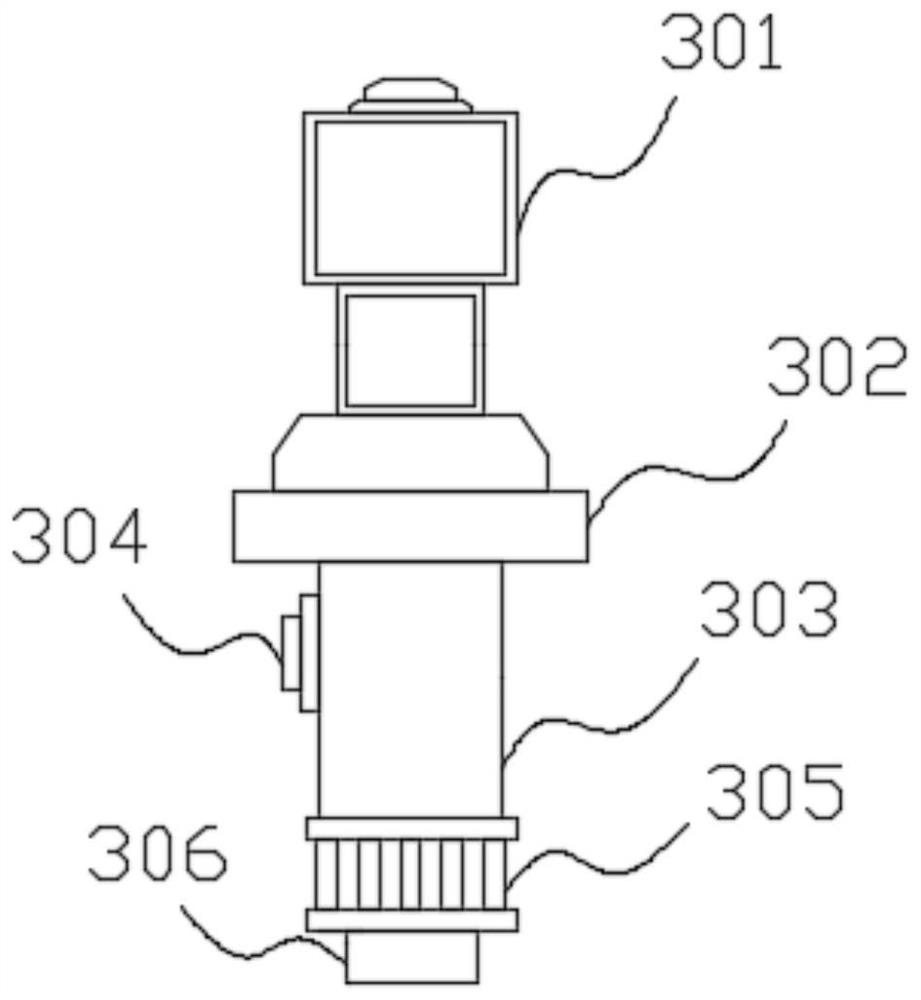

[0040] S3. Fix the struts 4 on both sides of the connecting seat 507 with bolts, use the ends of the struts 4 on both sides to support the first weighing mechanism 3, and the load cells 301 in the two first weighing mechanisms 3 Both are LC1760 weighing modules;

[0041] S4, fix the connecting rope 6 between the two load cells 301 to cooperate with the fixed assembly inclination sensor 7, and electrically co...

Embodiment 2

[0044] S1. Install the storage battery 12 and the alarm device main body 13 sequentially on the bottom surface of the casing 1, and install the second weighing mechanism 5 at the center part of the casing 1, so that the connection spring 506 in the mechanism is partially fixed to the connection seat 507, wherein The pressure sensor is M5600 pressure sensor;

[0045] S2. Fix the struts 4 on both sides of the connecting seat 507 with bolts, use the ends of the struts 4 on both sides to support the first weighing mechanism 3, and the load cells 301 in the two first weighing mechanisms 3 Both are LC1760 weighing modules;

[0046] S3, fix the connecting rope 6 between the two load cells 301 to cooperate with the fixed assembly inclination sensor 7, and electrically connect the inclination sensor 7, the two load cells 301 and the pressure sensor 504 to the battery 12 and alarm through the circuit The main body of the equipment 13, the main body of the alarm equipment 13 is connecte...

Embodiment 3

[0049] S1, the surface around the bottom of the PVC plastic shell 1 is fixedly connected with the mounting plate 16 through screw fit, so as to ensure that the shell 1 part can cooperate with the bottom mounting plate to communicate with the universal brake wheel 17 to move;

[0050] S2. Install the storage battery 12 and the main body of the alarm device 13 in sequence on the bottom surface of the casing 1, and install the second weighing mechanism 5 at the center part of the casing 1, so that the connection spring 506 in the mechanism is partially fixed to the connection seat 507, wherein The pressure sensor is M5600 pressure sensor;

[0051] S3. Fix the two struts 4 on both side surfaces of the connecting seat 507 with bolts, and use the ends of the two struts 4 on both sides to be respectively bolted to the mounting block 306 to complete the fixing of the first weighing mechanism 3 , and the load cells 301 in the two first weighing mechanisms 3 are all tank type load cells...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com