AGV concrete dump truck intelligent control system and control method

An intelligent control system, a technology of dump trucks, applied in the control/regulation system, vehicle position/route/height control, non-electric variable control, etc. Irregularity and other problems, to achieve real-time acquisition and management, avoid uncontrollable accidents, and avoid irregular transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] An AGV concrete dump truck intelligent control system, the implementation steps of the system are as follows:

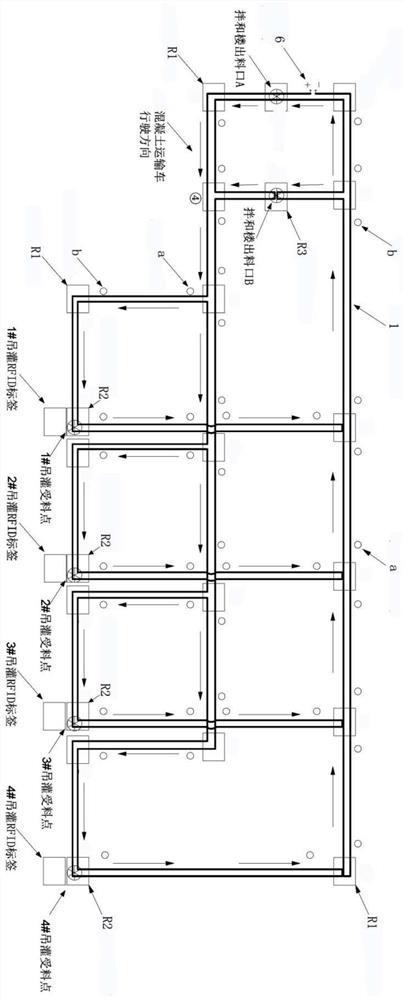

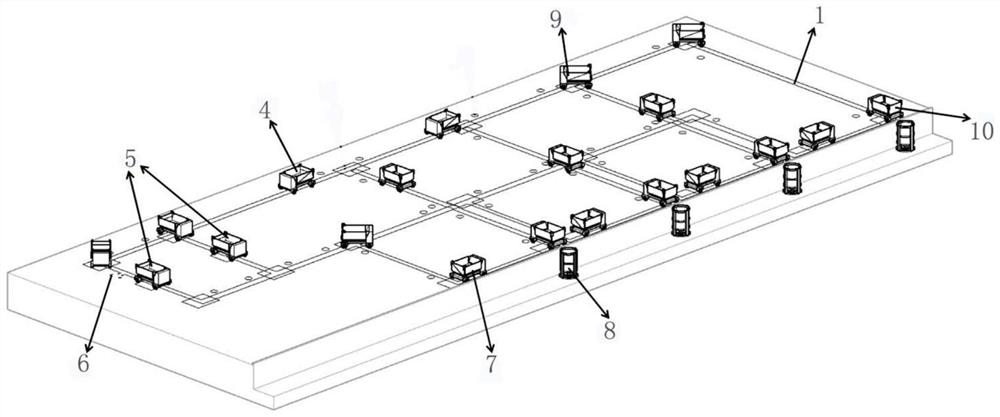

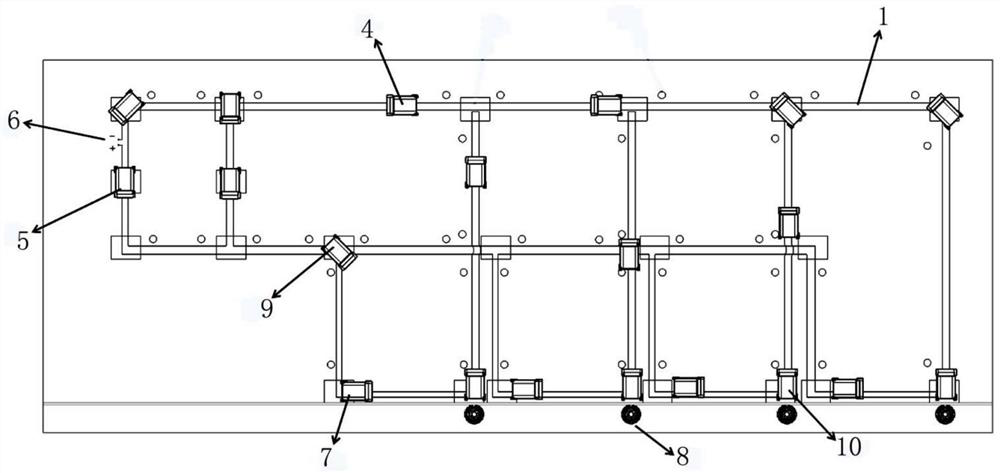

[0047] Step 1, such as figure 1 As shown, 4 hanging irrigation 8 and 2 outlets of the mixing building are determined, which are respectively marked as outlet A of the mixing building and outlet B of the mixing building. Among them, the location of the receiving point of the hanging irrigation is uncertain, depending on the real-time stop position of the hanging irrigation, and the dump truck will perform the alignment unloading task according to the RFID command label of the hanging irrigation.

[0048] Step 2: Design an AGV car path network consisting of two-wire electromagnetic tracks of AGV concrete transport vehicles from the positions of 4 hanging irrigation 8 and 2 mixing building outlets. Each electromagnetic guide rail is a combination of different straight lines. Therefore, when the dump truck is driving, it only needs to drive along the straight lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com