A tubular solid oxide fuel cell structure

A solid oxide, fuel cell technology, used in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of low power generation efficiency and reduced power generation at the entrance, and achieve improved overheating effect. The effect of power generation and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

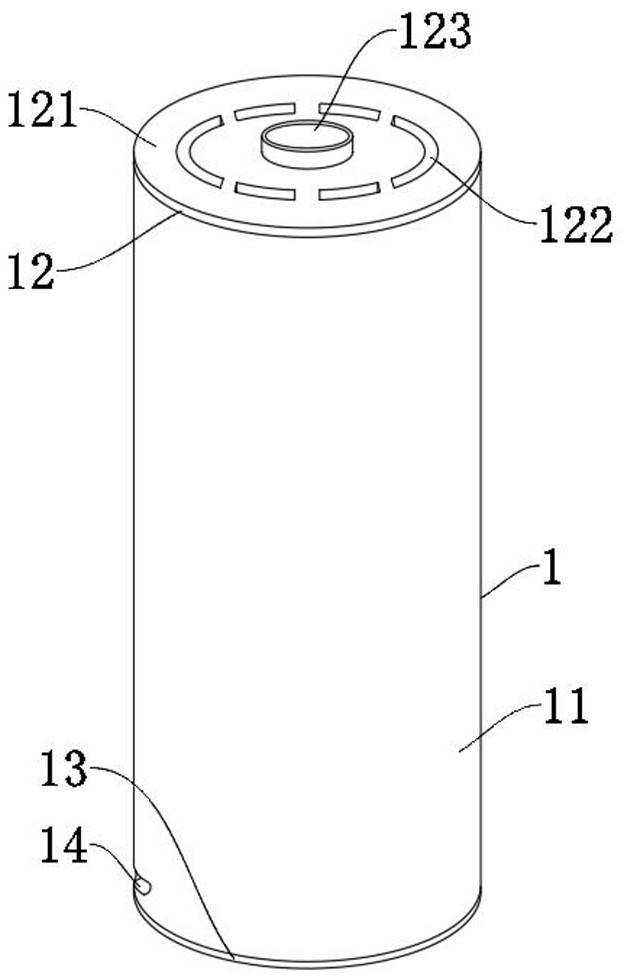

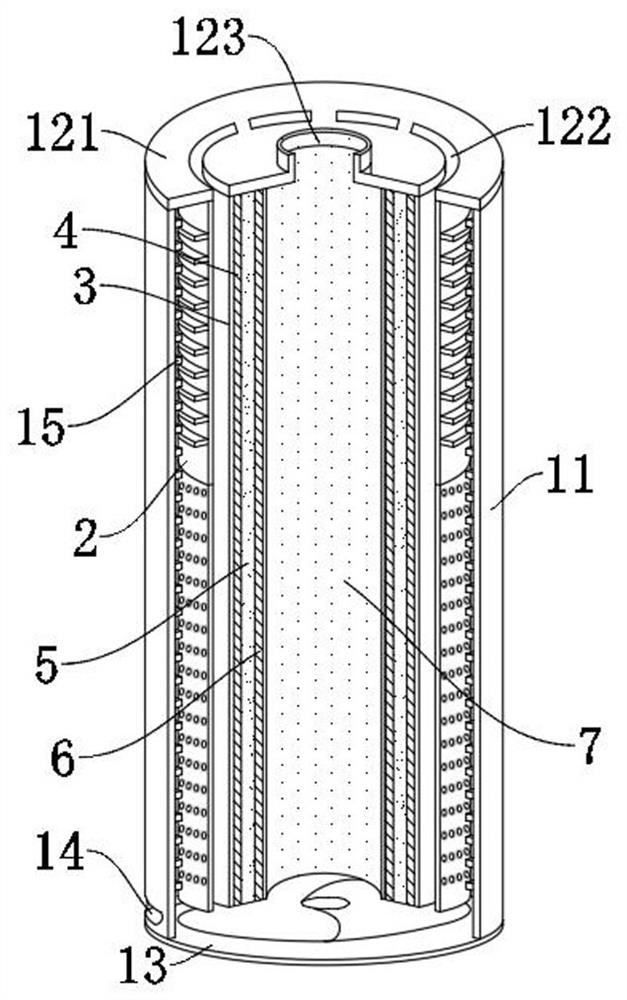

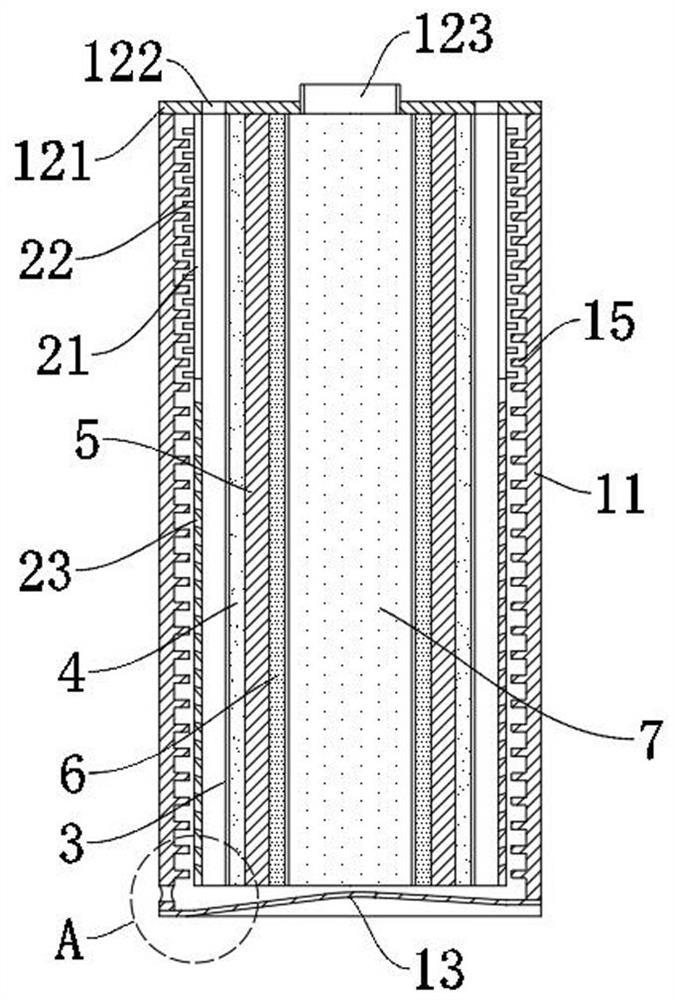

[0027] see Figure 1-Figure 5 , a tubular solid oxide fuel cell structure provided by the present invention, comprising a casing 1, a cathode reaction layer 4, an electrolyte layer 5 and an anode reaction layer 6, the anode reaction layer 6 is cylindrical, and the electrolyte layer 5 is wrapped around the anode Outside the reaction layer 6, the cathode reaction layer 4 is wrapped on the outside of the electrolyte layer 5, and the cathode reaction layer 4 is arranged inside the shell 1, and the shell 1 includes a middle shell tube 11, an end cover 12 and a bottom cover 13, and the end cover 12 and the bottom cover 13 are respectively fixed on the upper and lower ends of the middle casing 11, and the inside of the anode reaction layer 6 is pasted with an anode support layer 7, which is made of a breathable and heat-resistant material, which is conducive to ventilation and heat dissipation, and the anode support layer 7 The surface is smooth, which is conducive to drainage. The o...

Embodiment 2

[0034] On the basis of Embodiment 1, the difference is that: the first support ring 15 is in a spiral shape (not shown), and the first support ring 15 is in a spiral shape, the air guide tube 22 cooperates with the first support ring 15, and the first support ring 15 and the air guiding cylinder 22 are designed to distribute spirally downward, so that the top waste heat is condensed at the entrance due to the heat absorption of the reaction, and the generated water vapor can flow downward through the spirally downward first support ring 15 and the air guiding cylinder 22, and the drainage effect is better.

Embodiment 3

[0036] On the basis of Embodiment 1, the difference is that the cover body 121 is a hollow structure (not shown), and the inner cavity of the cover body 121 communicates with the heat recovery cavity, so that waste heat is more conducive to converging around the fuel adding tank 123, and more It is beneficial to provide heat for the reaction at the entrance of the fuel adding tank 123 and prevent supercooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com