Self-repairing type insulation treatment process for motor rotor

A technology of insulation treatment and motor rotor, applied in the field of rotor, can solve the problems of damage expansion, insulation performance degradation and failure of insulating paint layer, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

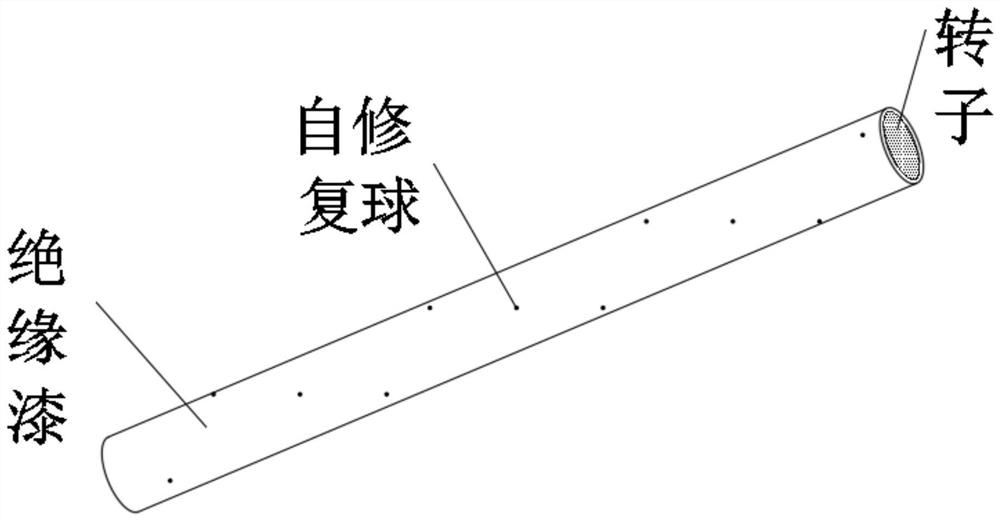

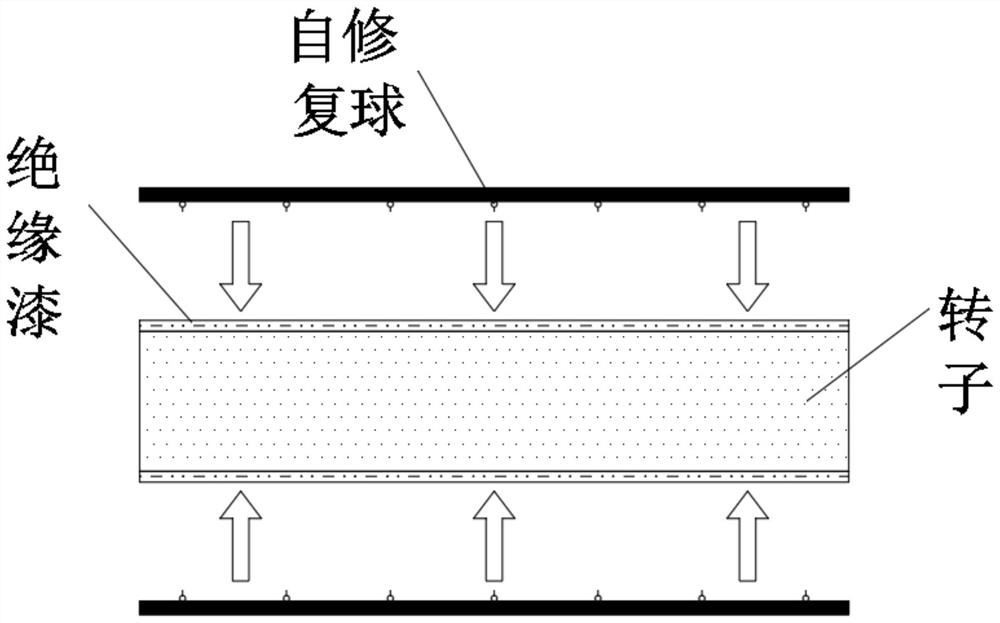

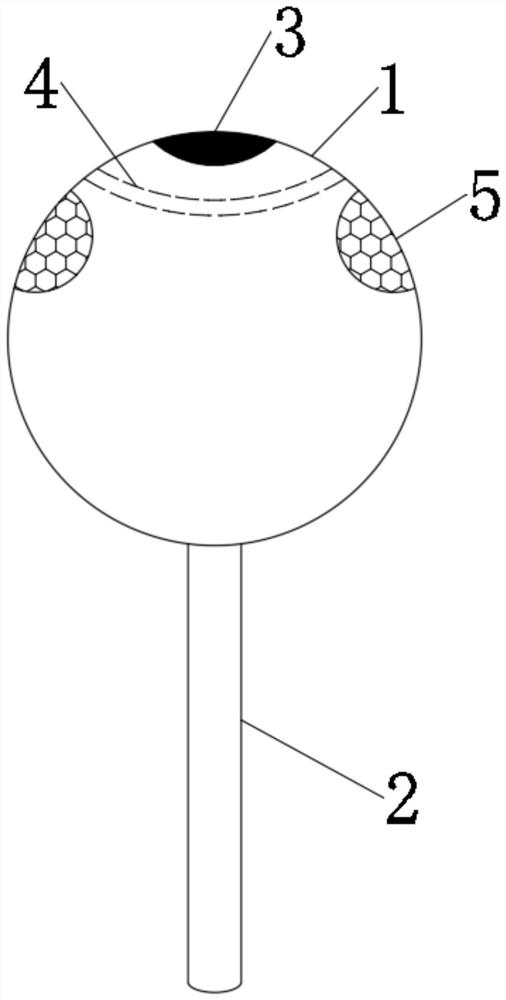

[0044] see Figure 1-2 , a motor rotor self-repairing insulation treatment process, comprising the following steps:

[0045] S1. Preheat the rotor, the preheating time is 10min, and the preheating temperature is 125°C;

[0046] S2. Immerse the rotor in the paint pot, convey the insulating paint and vacuumize until no air bubbles are generated, and soak the paint for 20 minutes;

[0047] S3. Evenly absorb multiple self-repairing balls through the strip-shaped magnetic plate, then align the extension direction of the rotor and press it, repeat the above operation until the entire rotor is covered;

[0048] S4, heat and gel the rotor to form a surface paint film, and then continue heating to force the insulating paint to fully cure;

[0049] S5. The self-repairing ball is pre-embedded in the insulating varnish, and after the damage is sensed, the stored insulating varnish is released under the action of centrifugal force for repair.

[0050] Before transporting the insulating ...

Embodiment 2

[0060] A motor rotor self-repairing insulation treatment process, comprising the following steps:

[0061] S1. Preheat the rotor, the preheating time is 11min, and the preheating temperature is 135°C;

[0062] S2. Immerse the rotor in the paint pot, transport the insulating paint and vacuumize until no bubbles are generated, and soak the paint for 30 minutes;

[0063] S3. Evenly absorb multiple self-repairing balls through the strip-shaped magnetic plate, then align the extension direction of the rotor and press it, repeat the above operation until the entire rotor is covered;

[0064] S4, heat and gel the rotor to form a surface paint film, and then continue heating to force the insulating paint to fully cure;

[0065] S5. The self-repairing ball is pre-embedded in the insulating varnish, and after the damage is sensed, the stored insulating varnish is released under the action of centrifugal force for repair.

[0066] Before transporting the insulating varnish in step S2, ...

Embodiment 3

[0071] A motor rotor self-repairing insulation treatment process, comprising the following steps:

[0072] S1. Preheat the rotor, the preheating time is 12min, and the preheating temperature is 145°C;

[0073] S2. Immerse the rotor in the paint pot, transport the insulating paint and vacuumize until no bubbles are generated, and soak the paint for 40 minutes;

[0074] S3. Evenly absorb multiple self-repairing balls through the strip-shaped magnetic plate, then align the extension direction of the rotor and press it, repeat the above operation until the entire rotor is covered;

[0075] S4, heat and gel the rotor to form a surface paint film, and then continue heating to force the insulating paint to fully cure;

[0076] S5. The self-repairing ball is pre-embedded in the insulating varnish, and after the damage is sensed, the stored insulating varnish is released under the action of centrifugal force for repair.

[0077] Before transporting the insulating varnish in step S2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com