Single cell separation system and method based on droplet microfluidics

A single-cell separation, microfluidic chip technology, applied in the field of microfluidics, can solve problems such as lysis, affecting cell activity, and damage to microfluidic chips, and achieve high-speed and effective separation, low cost, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

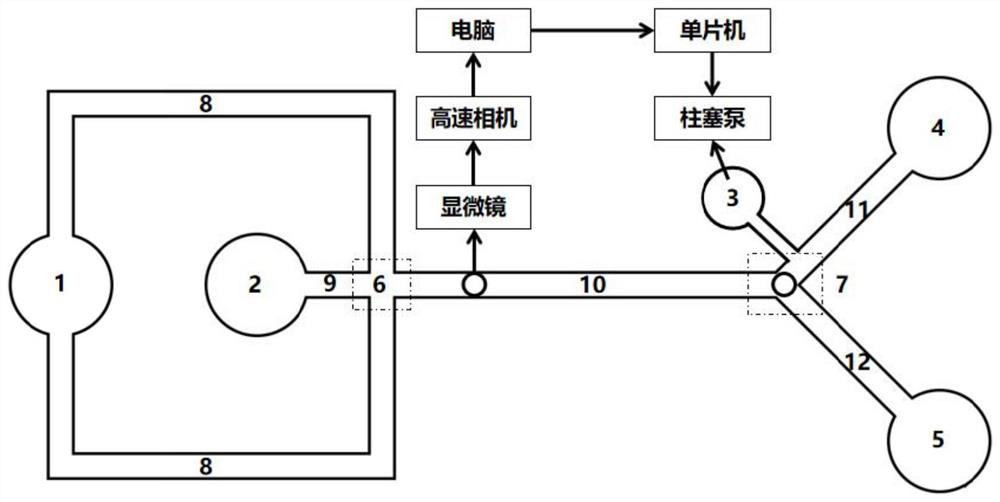

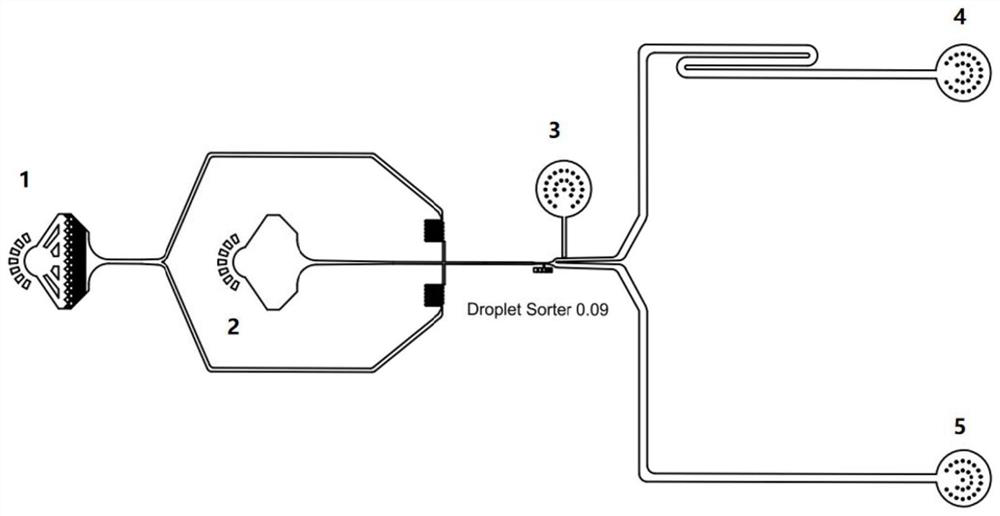

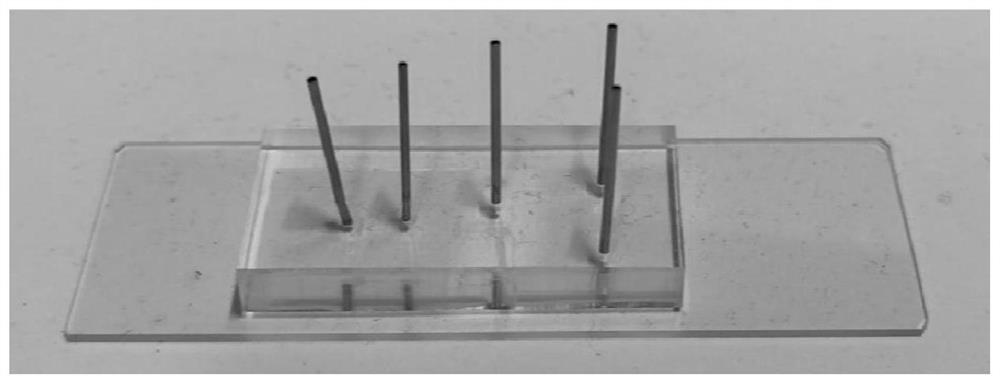

[0045] Such as figure 1, a single-cell separation system based on droplet microfluidics, including a microfluidic chip, a droplet image detector (microscope and high-speed camera), signal analysis and sorting control unit (computer and single-chip microcomputer), and hydraulic power components ( plunger pump);

[0046] The microfluidic chip is specifically provided with the following structures: oil phase inlet 1, water phase inlet 2, negative pressure port 3, collection port 4, waste liquid port 5, droplet generation cross channel 6, herringbone channel 7, oil phase liquid inlet channel 8, water phase liquid inlet channel 9, liquid outflow channel 10, liquid collection channel 11 and waste liquid channel 12; the oil phase inlet 1 is connected to the oil phase liquid inlet channel 8; the water phase inlet 2 is connected to the water Phase liquid inlet channel 9; the intersection of the oil phase liquid inlet channel 8 and the water phase liquid inlet channel 9 crosses in the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap