Flotation method capable of protecting integrity of graphite flakes

A graphite flake and integrity technology, used in flotation, solid separation, grain treatment, etc., can solve the problems of large flake graphite damage, excessive grinding times, long process structure, etc., to reduce the number of regrinding and processing. The effect of improving the regrinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

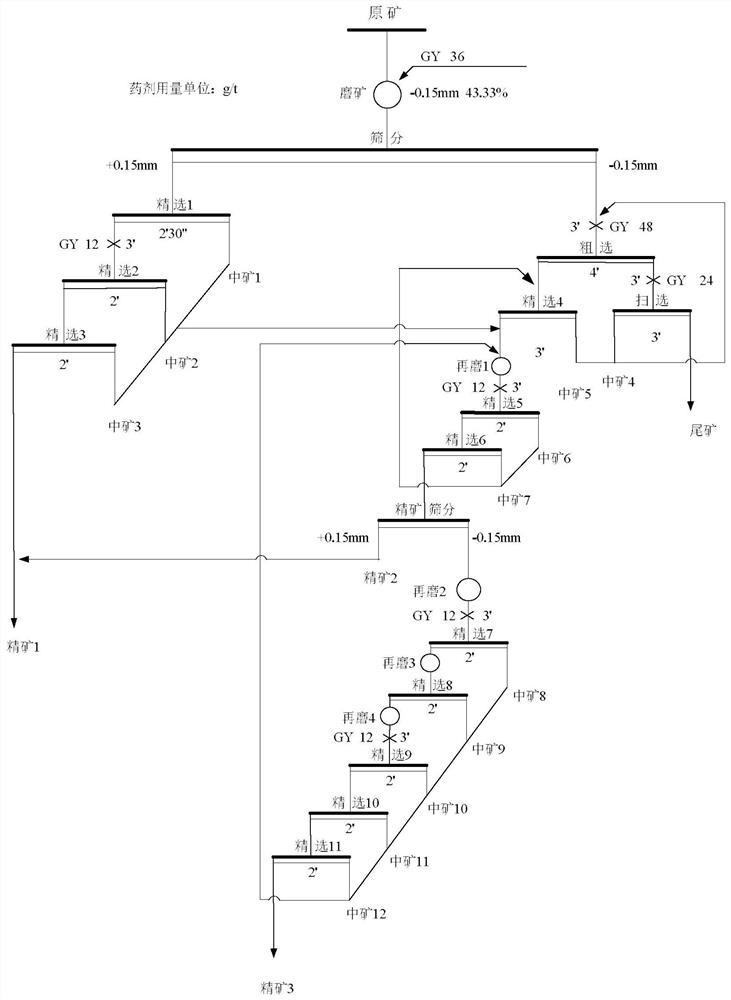

[0041] The flotation method provided by the invention that can protect the integrity of graphite flakes adopts grinding-classification flotation, firstly grinds and screens the raw ore, and then selects the Zhengmu concentrate three times to obtain Zhengmu high-carbon graphite.

[0042] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0043] refer to figure 1 , the flotation method that can protect the integrity of graphite flake provided by the invention specifically comprises the following steps:

[0044] Step 1: Grinding

[0045] Use a rod mill to grind -2mm graphite raw ore (fixed carbon grade is 14.89%), and the grinding concentration is 60wt%. The ore fineness is -0.15mm, accounting for 43.33%.

[0046] In the present invention, GY is used as the agent having both collecting property and foaming property. GY is a compound agent composed of normal alkanes with 10-14 C atoms and 2# oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com