Preparation method of high-purity palladium powder

A kind of palladium powder and high-purity technology is applied in the field of preparation of high-purity palladium powder, and can solve the problem that the purity of palladium powder cannot meet high-purity requirements and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

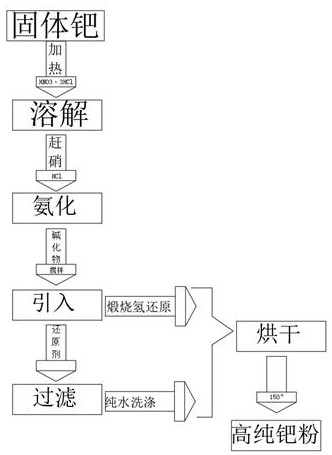

Image

Examples

Embodiment Construction

[0020] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0021] See figure 1 The present invention provides a technical solution: a method of preparing high purlad palladium powder comprising heating the solid palladium metal after being heated into a beaker with HNO3 · 3HCl to dissolve, dissolve the solubility; dissolve is heated to boiling Up to the brown-free yellow gas, it is obtained from a solution after a nitride; the solution is added to the solution after the above-mentioned nitrate, the pH of the solution is adjusted, and the solution is stopped when the solution is tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com