Perovskite thin film preparation device

A technology of thin film preparation and perovskite, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

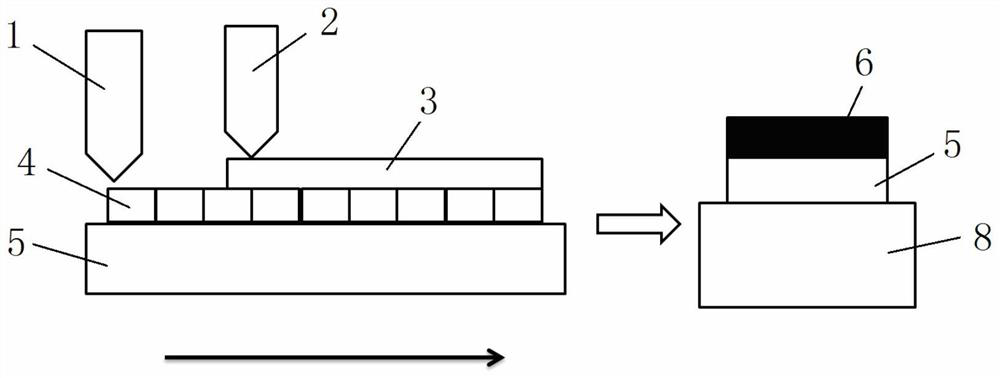

[0026] This embodiment is directed to the rigid substrate 5, the substrate transport mechanism of the present embodiment can employ a conventional transmission belt conveyor, including a transmission belt and a transmission roller provided at both ends of the transmission belt, and any conveying roller is driven by a motor. Further, drive the transfer belt to move, and the rigid substrate 5 is placed on the transmission belt.

[0027] The specific preparation process of this embodiment is as follows:

[0028] First, the substrate is prepared, the rigid substrate 5 may be a transparent conductive glass or a metal sheet, and the prepared rigid substrate 5 is cleaned, the cleaning process, which can be cleaned with ethanol, isopropanol, etc. The area preparation can be cleaned with a neutral cleaning solution to ensure the cleanliness of the rigid substrate 5, the cleaning process being known in the art, and then the preparation of the functional layer such as the electrode layer is ...

Embodiment 2

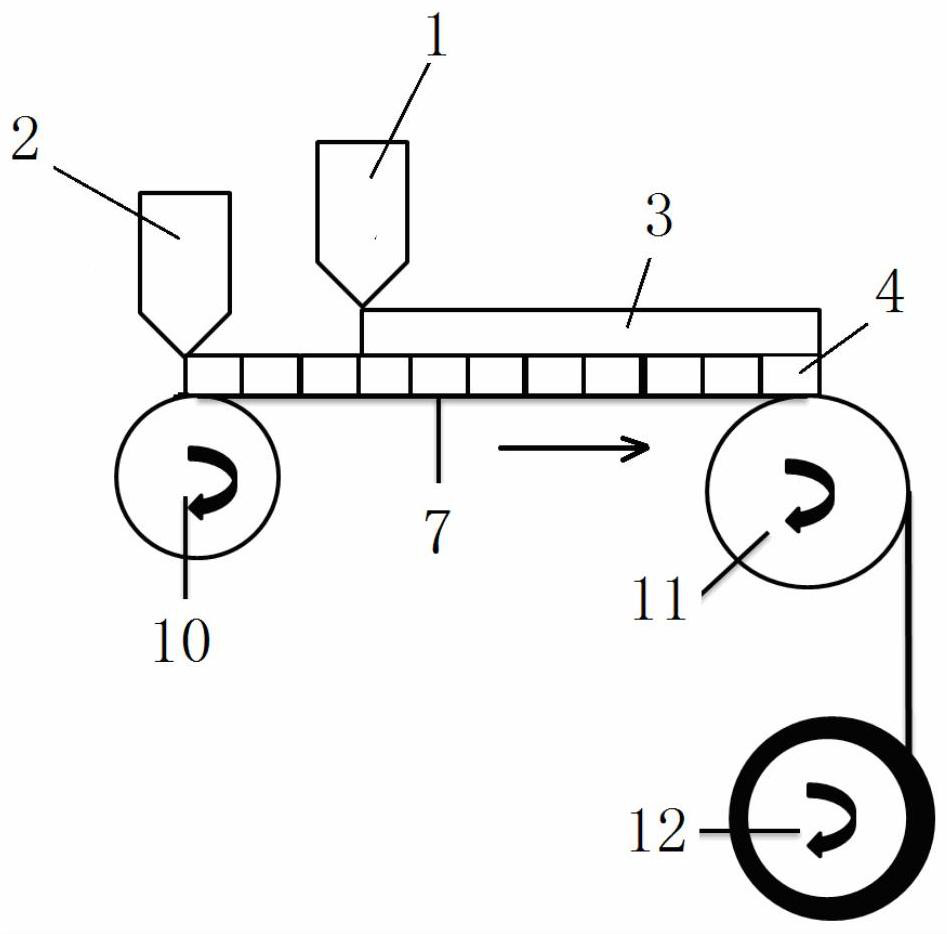

[0035] This embodiment is directed to the flexible substrate 7, the substrate transport mechanism in this embodiment is based on a roll to the volume device. Such as image 3 As shown, the substrate transport mechanism in the present embodiment includes a discharge reel 10, a steering drum 11, and a collecting reel 12, wherein the flexible substrate 7 is initially rolled on the discharge reel 10, and the flexible substrate 7 The rendering of the returning roller 11 is rolled on the collector reel 12, wherein the steering drum 11 funs as a tensioned reel, so that the discharge roll 10 and the flexible substrate between the steering drum 11. 7 has a certain tension to remain straight, the calcium ore coating film adjustment device and the anti-solvent coating film adjustment device are placed above the flexible substrate 7 between the discharge reel 10 and the steering drum 11, the discharge reel The 10 and the collector reel 12 respectively drive through different motor, and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com