Square steel treatment auxiliary device

A technology of auxiliary device and mounting frame, which is used in shearing devices, accessories of shearing machines, maintenance and safety accessories, etc., can solve problems such as damage to the cutter, dust hazards, affecting the quality of workpiece cutting, and avoid residual waste residues. , Improve the service life and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

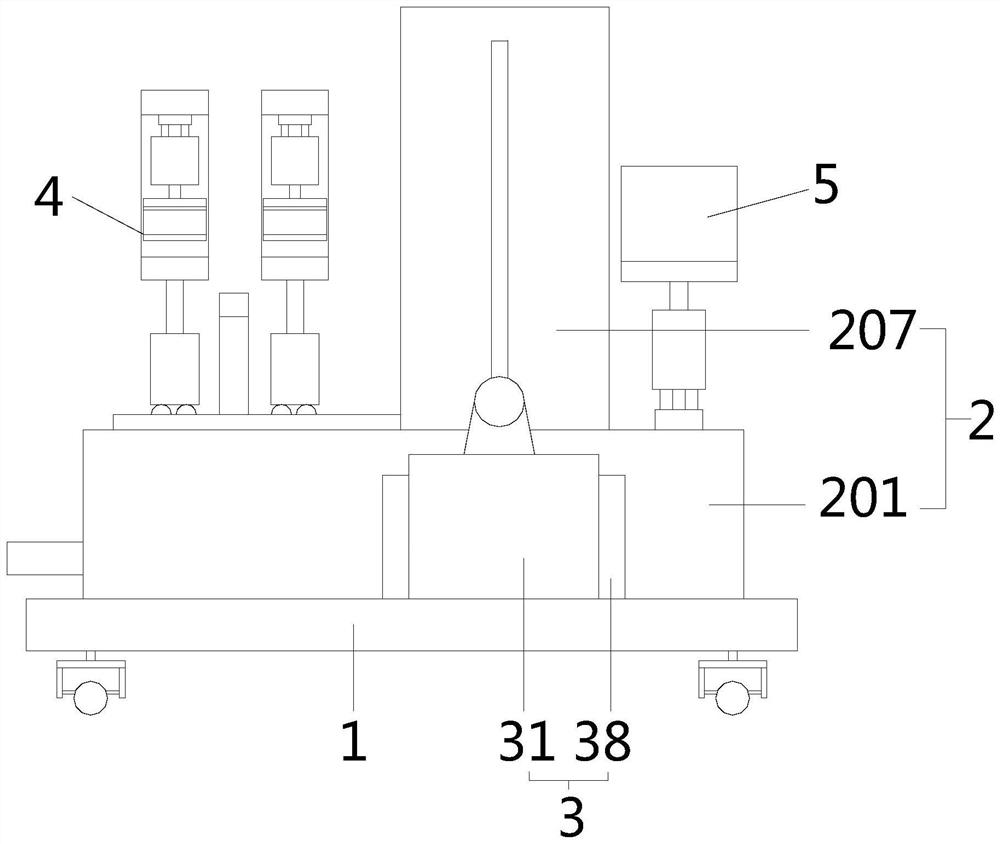

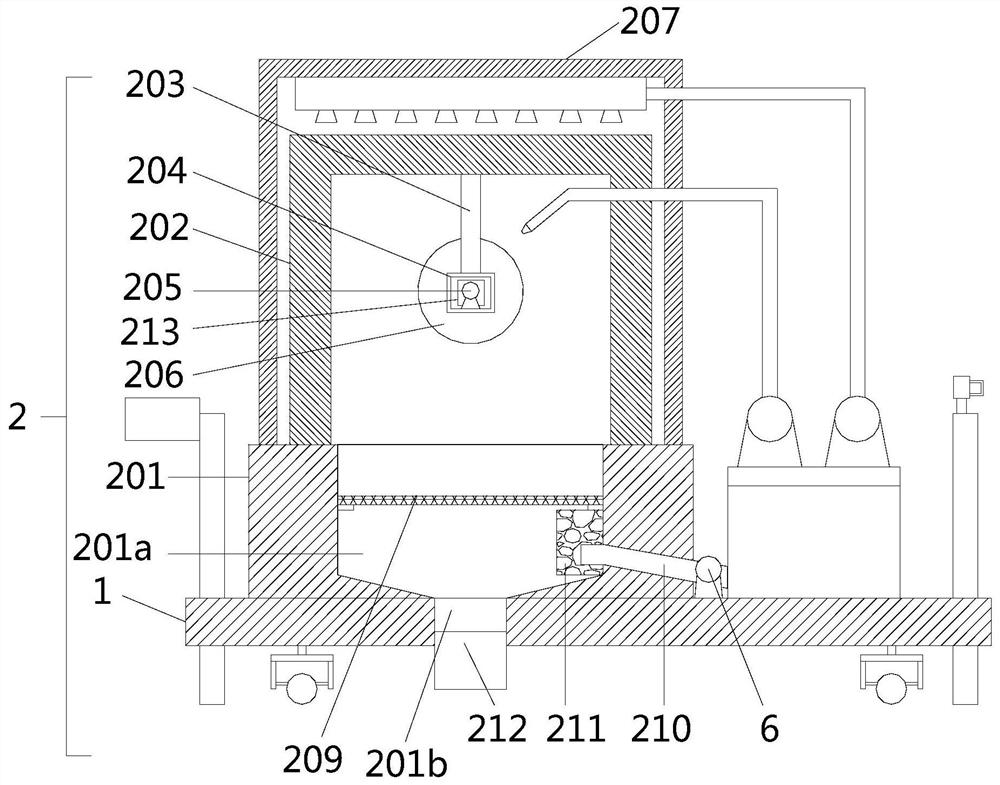

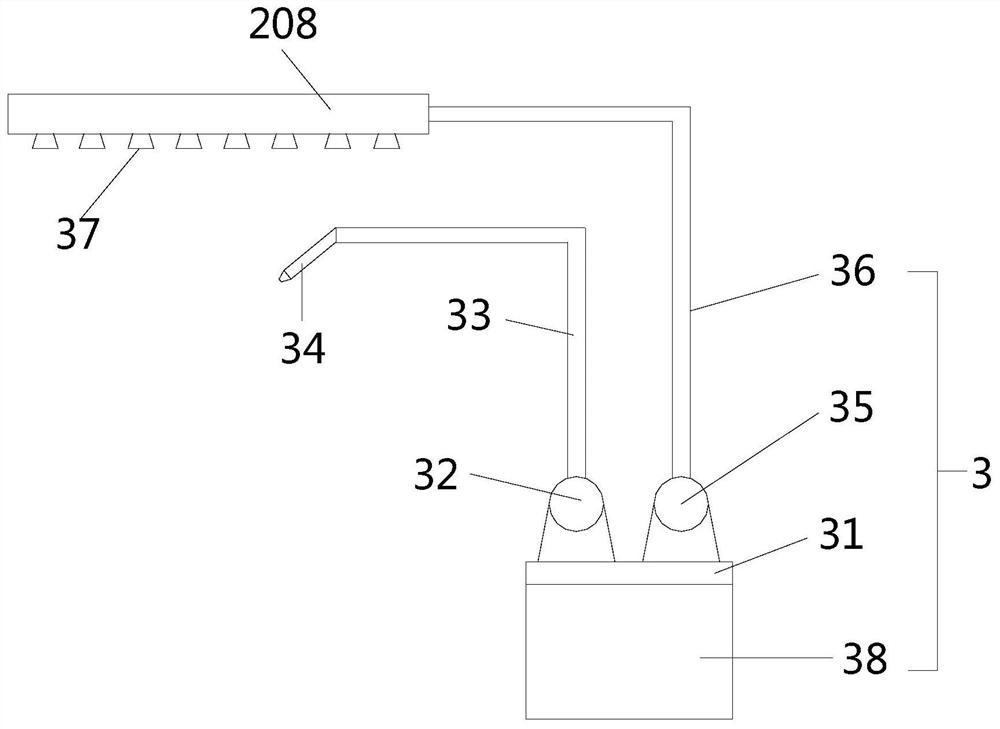

[0039] like Figure 1 - Figure 3 As shown, a square steel treatment assist device provided in Example 1 of the present invention includes a base 1, and the upper end of the base 1 is provided with a processing assembly 2 and a dust collecting cooling assembly 3, and the processing assembly 2 includes a carrier plate 201, said The carrier plate 201 is provided with a gate mount 202 that is provided with a connecting rod 203 at the lower surface of the beam, the connecting rod 203, where the outer end connecting the mouthpiece 204, the mouth mount 204 A rotating motor 205 having a rotating end is horizontal direction and a cutter 206 disposed on the rotating motor 205 rotating, the door type mount 202 is provided with a door type guard 207, and the door shell 207 is close to the door type. One end of the top of the mounting frame 202 is provided with a water cassette 208, and the upper end of the carrier plate 201 is provided with a precipitation tank 201a located at the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com