Grinding device for bearing ring of shield tunneling machine

A technology of bearing rings and shield machines, which is applied in the direction of grinding machines, grinding frames, grinding beds, etc., can solve the problems of incomplete grinding and low precision, and achieve the effect of smooth workflow and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

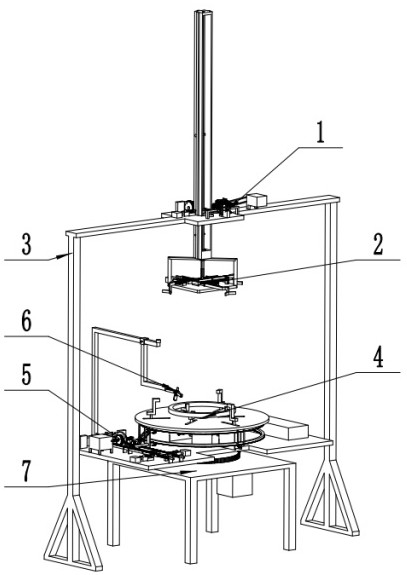

[0022] Example: Reference figure 1 A shield machine bearing ring grinding device shown in —9, wherein the lifting device 1 and the fixing device 2 are arranged on the fixed frame 3, the clamping device 4 is arranged on the fixed platform 7, the clamping control device 5 and the grinding device 6 is set on the clamping device 4 .

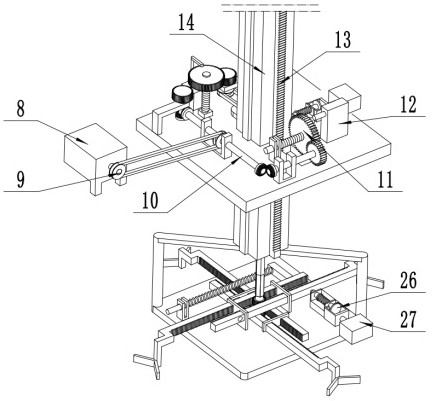

[0023] refer to figure 2- Lifting device 1 shown in 3, wherein on fixed mount 3, be fixedly provided with bearing platform, be fixedly provided with lifting fixed power source 8 on the bearing platform, lift fixed power source 8 is connected with synchronous transmission shaft 10 by synchronous belt-9, The synchronous transmission shaft 10 is rotated and arranged on the carrying platform, the first end of the synchronous transmission shaft 10 cooperates with the lifting drive gear 11 through the gear set, the lifting driving gear 11 is slidably arranged on the carrying platform and connected with the disconnected power cylinder 12, and the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com