Full-automatic plane labeling machine

A fully automatic, labeling machine technology, applied in labeling machines, labeling, marking rigid planes, etc., can solve problems such as label wrinkles, label bulging, and uneven bonding of labels and labeling parts, so as to avoid wrinkles and air bubbles , Guarantee the effect of flatness and complete adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

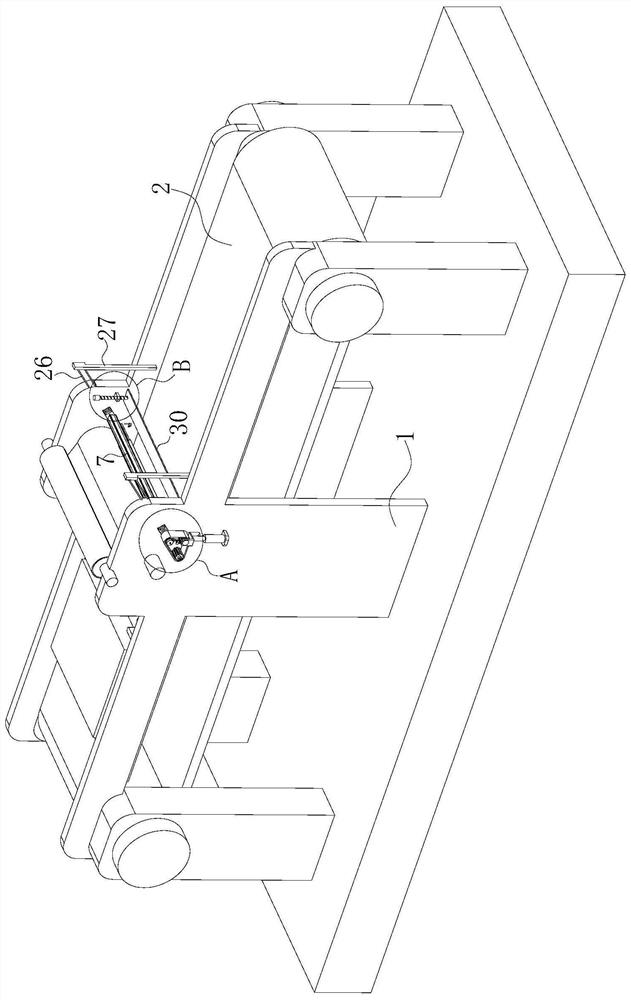

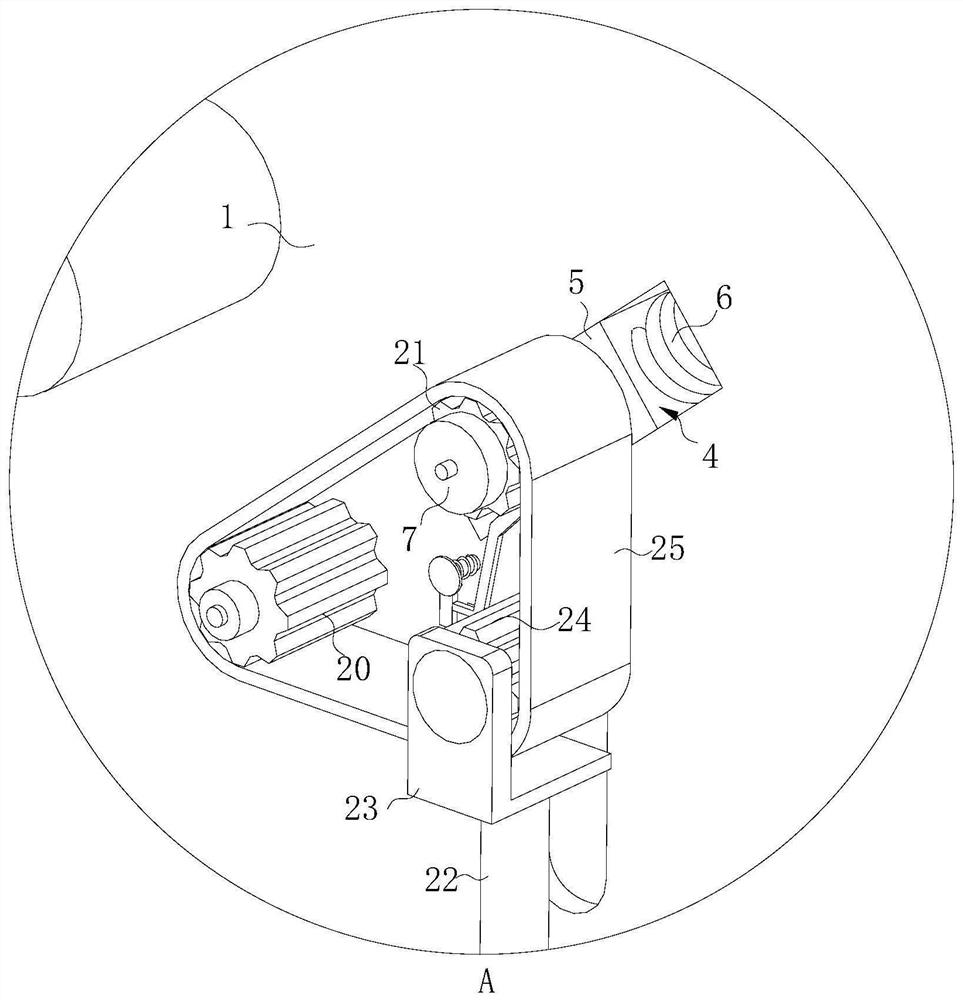

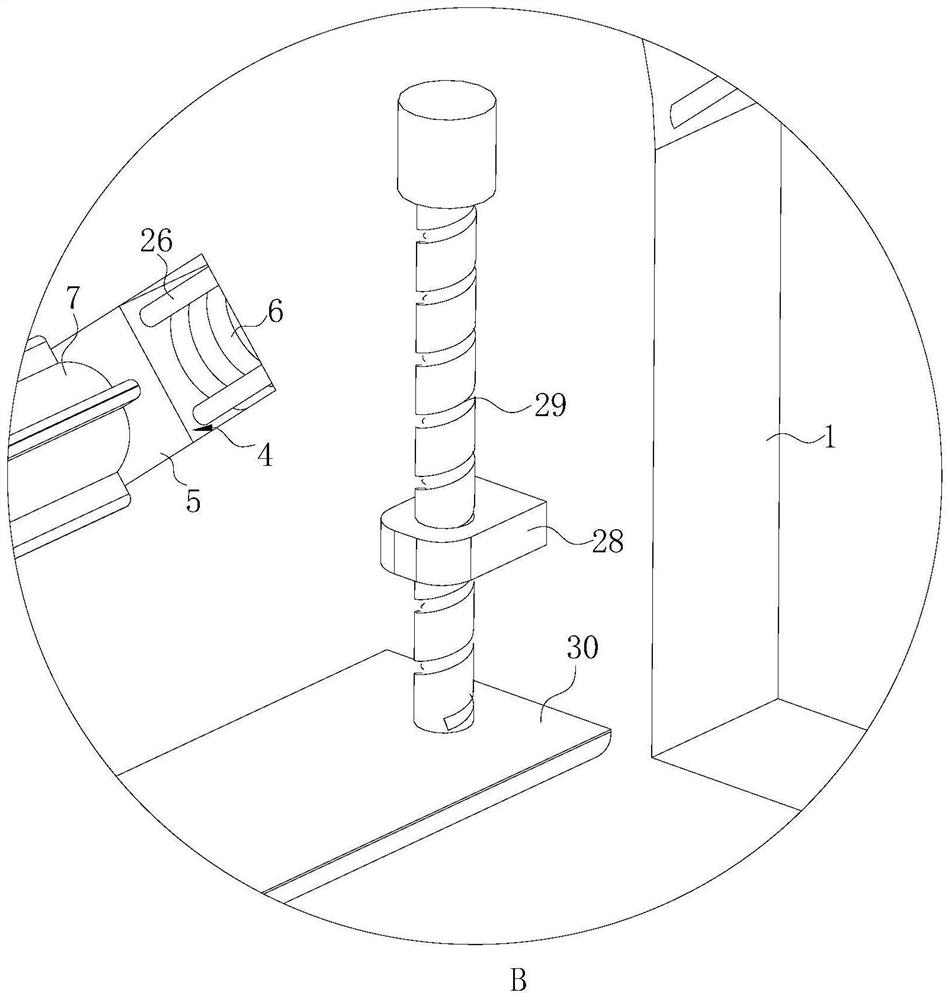

[0033] see Figure 1-12 , the present invention provides a technical solution: a fully automatic flat labeling machine, including a fixed bracket 1, the internal transmission of the fixed bracket 1 is connected to the conveyor belt 2, and the top of the conveyor belt 2 is connected to several groups of positioning along the edge array of the conveyor belt 2. Mechanism, the positioning mechanism is used for positioning the labeling parts, the first rack 3 is fixedly connected to the outer wall of the positioning mechanism, the labeling mechanism is connected to the inner wall of the fixed bracket 1, and the labeling mechanism is provided below the labeling mechanism. The labeling mechanism It is used to tighten the two ends of the label. There are two first chute 4 inside the fixed bracket 1, and the first slider 5 is slidably connected to the inside of the two first chute 4. The top surfaces of the two first sliders 5 are Both are fixedly connected with a first spring 6, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com