Stay wire binding wire manufacturing device

A technology for manufacturing devices and controllers, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc. It can solve problems such as uneven size of binding wire loops, inconvenient operation, economic losses of production enterprises and power enterprises, and achieve Improve work efficiency and process quality, facilitate operation and portability, and reduce work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

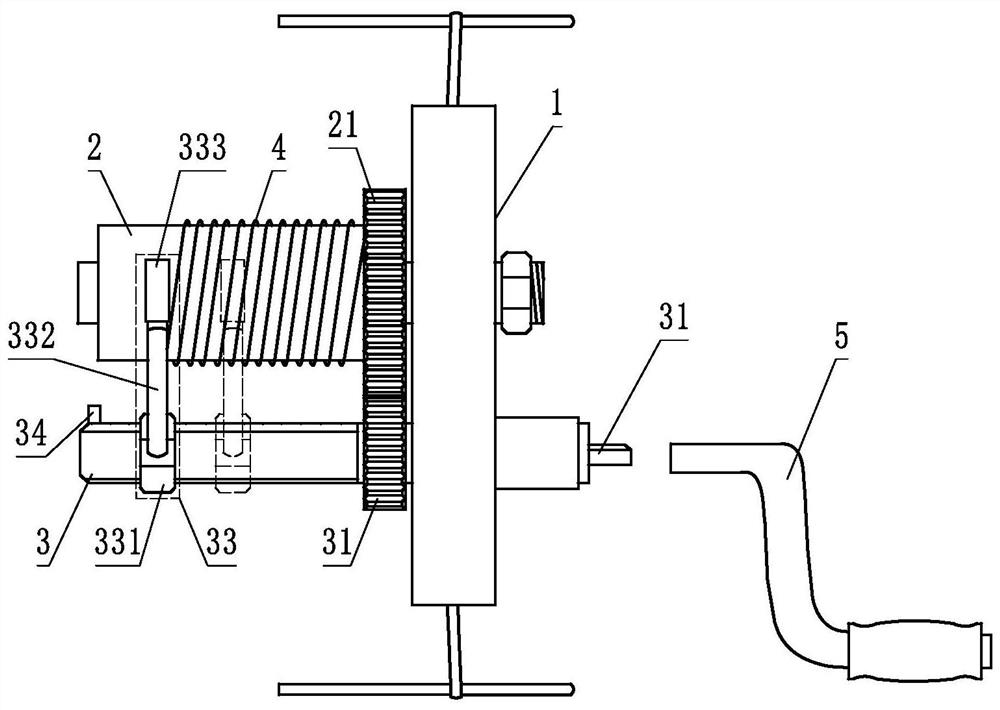

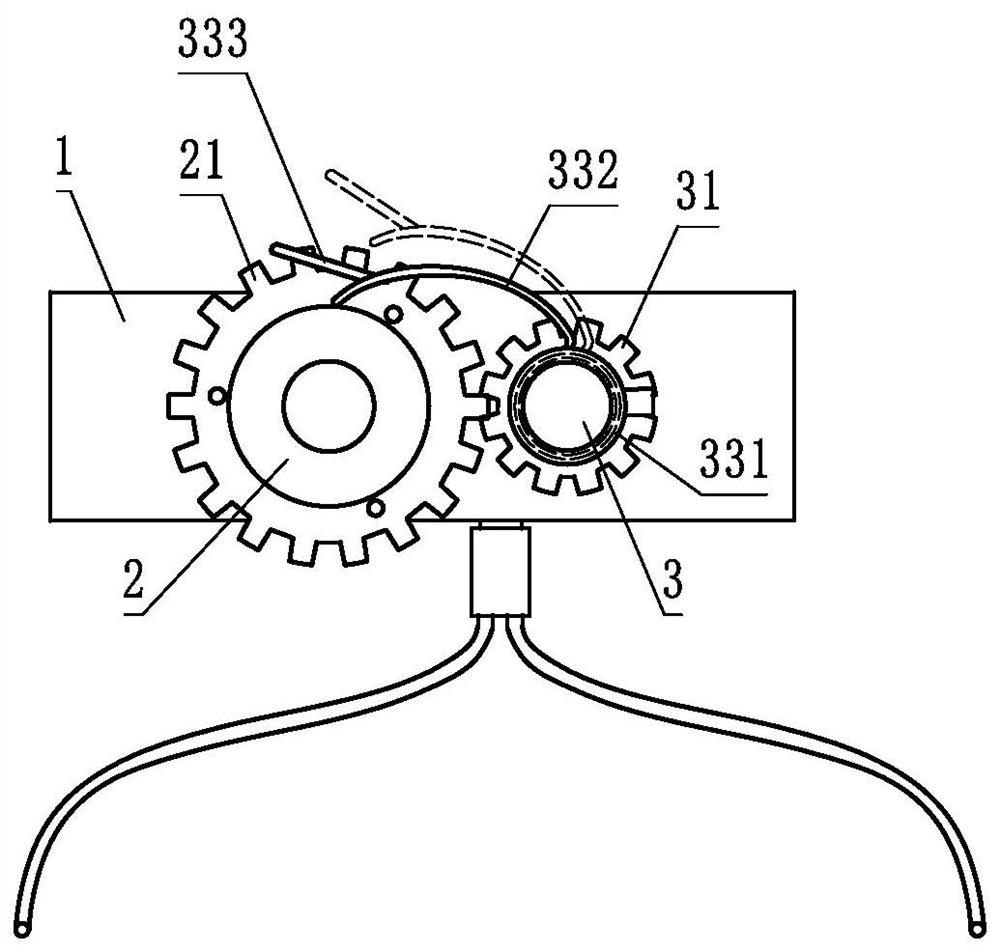

[0034] This embodiment provides a device for making a pulling wire binding wire, see Figure 1-2, the device includes a fixing base 1. In this embodiment, the fixing base 1 includes a supporting foot frame and a long fixing bracket. The fixing bracket is laterally fixed on the supporting foot frame, and the fixing bracket is provided with a winding roller 2 and Limiting roller 3, the winding roller 2 and the limiting roller 3 are arranged side by side and are both perpendicular to the fixing bracket, that is, one end of the winding roller 2 and the limiting roller 3 is fixed on the fixing bracket, and the winding roller 2 and The limit roller 3 is respectively provided with a gear A21 and a gear B31 at one end close to the fixed bracket. The gear A21 and the gear B31 mesh with each other. The limit roller 3 is provided with a limit component 33, which can be opposite to the limit roller 3. Move and its free end can be in contact with the take-up roller 2 or its free end can be...

Embodiment 2

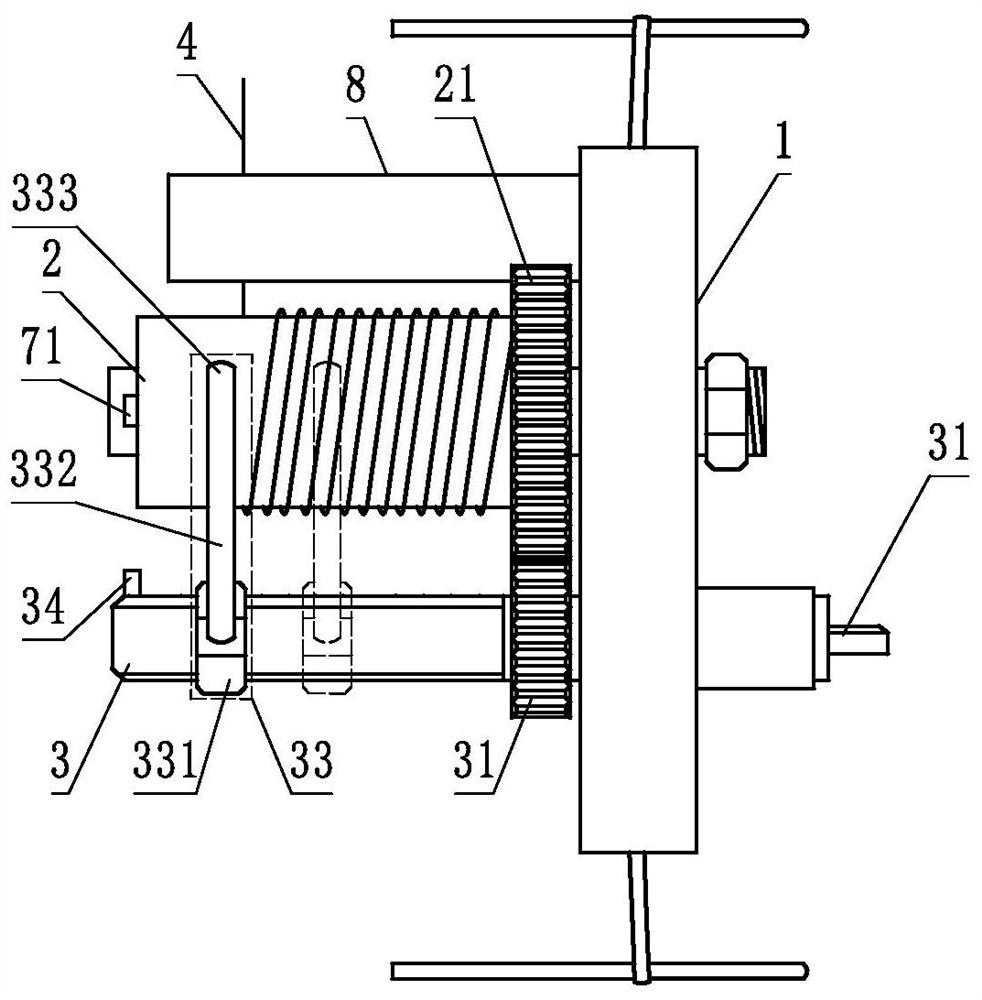

[0040] Compared with Embodiment 1, the difference of this embodiment is that a counting assembly is provided, and the power mechanism is a motor. The counting assembly includes an encoder 71 and a controller 72, see Figure 3-4 , in this embodiment, the controller 72 can be arranged on the fixed seat 1, the encoder 71 is arranged on one side of the winding roller 2 and can rotate with the winding roller 2, and the encoder 71 and the signal input of the controller 72 The motor is connected to the signal output end of the controller 72. When using, first set the required length parameters of the binding wire 4 in the controller 72 according to the needs. In this embodiment, it is preferable to set multiple sets of length parameters of the binding wire 4. The length parameters of the binding wire 4 correspond to different switching modes. In this way, it is convenient for the staff to operate and improve the production efficiency of the binding wire 4. At the same time, the corres...

Embodiment 3

[0044] Compared with the embodiment 1 or 2, the difference of this embodiment is that the winding roller 2 is provided with a wire withdrawal assembly 9, the wire withdrawal assembly 9 includes an outer sleeve 91 and an inner sleeve 92, and the outer sleeve 91 is provided with a spring. Tube 93, the inner sleeve 92 is nested in the outer sleeve 91 and can be telescopically moved in the outer sleeve 91 under the action of the spring tube 93. In this embodiment, in order to fix the state of the inner sleeve 92 in the outer sleeve 91, To avoid its rotation, preferably the inner sleeve 92 and the outer sleeve 91 are connected by a spring tube 93; the outer sleeve 91 is provided with a plurality of through holes 911, and the inner sleeve 92 is provided with a resilient connecting rod 921, the connecting rod 921 One end is provided with a protrusion 922, and the protrusion 922 can expand and contract in the through hole 911 of the outer sleeve 91. In this embodiment, preferably, two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com