A kind of air flotation method and its blue-green algae pressure reuse treatment system

A treatment system and reuse technology, applied in the field of water purification, can solve the problems of large bubble rising volume, unsatisfactory water purification effect, and reduced bubble floc capacity, etc., to achieve the effect of convenient collection and improvement of air flotation purification processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

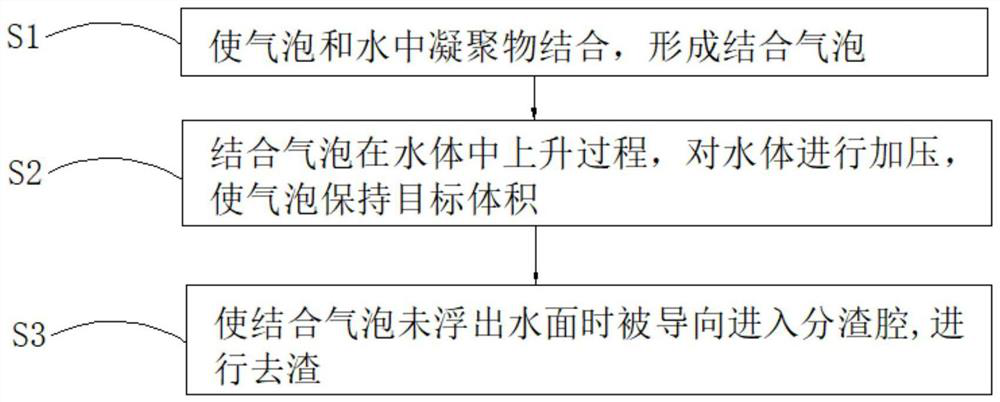

[0040] refer to figure 1 , a kind of air flotation method, comprises the following steps:

[0041]S1: Combine air bubbles with condensate in water to form combined air bubbles;

[0042] S2: Combining the rising process of the air bubbles in the water body, pressurizing the water body to keep the air bubbles at a target volume, preferably, the diameter of the air bubbles is 10-100 μm;

[0043] S3: The combined air bubbles are guided into the slag removal chamber when they have not surfaced to remove slag.

[0044] This air flotation method adjusts the pressure that the bubbles bear when they do not surface the water, maintains the target volume during the rise of the bubbles in the water body, maintains the specific surface area of the small bubbles and the adhesion to the flocs in the water body, and improves the air flotation purification treatment. Effect.

[0045] The air flotation method in this embodiment can be used for the purification of water bodies, including th...

Embodiment 2

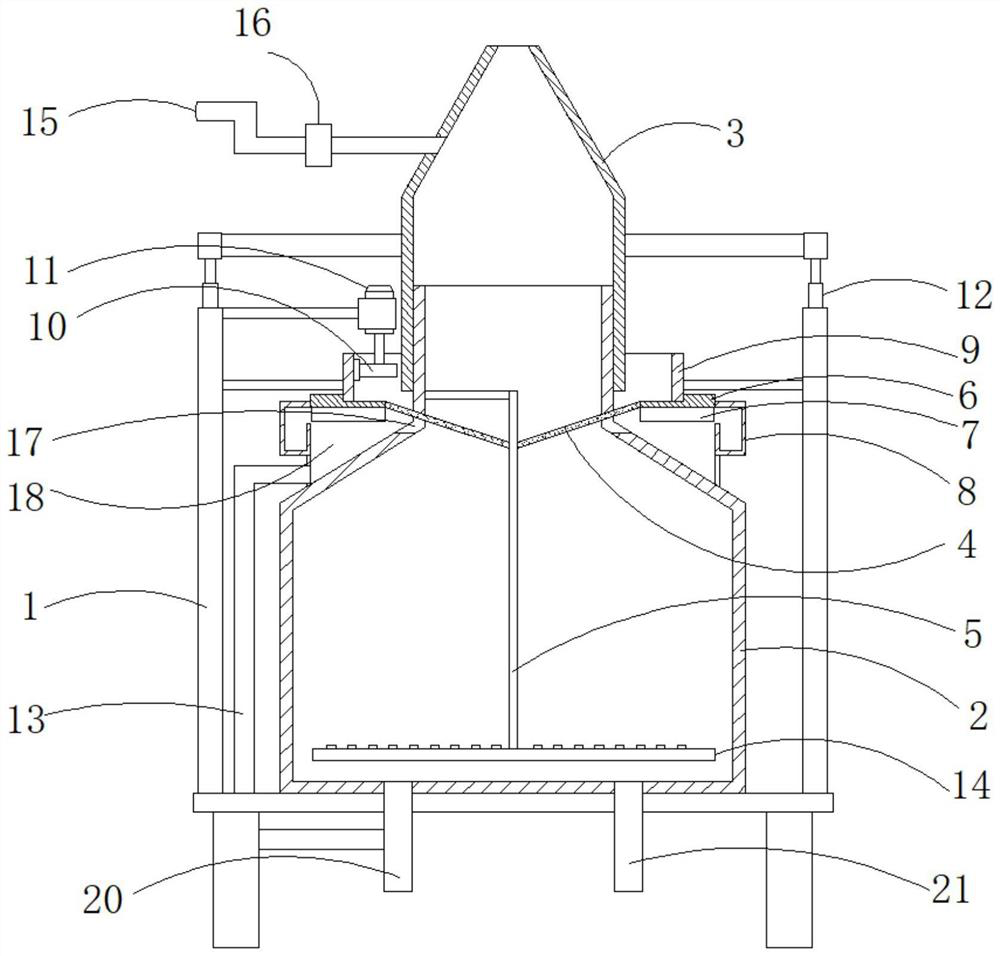

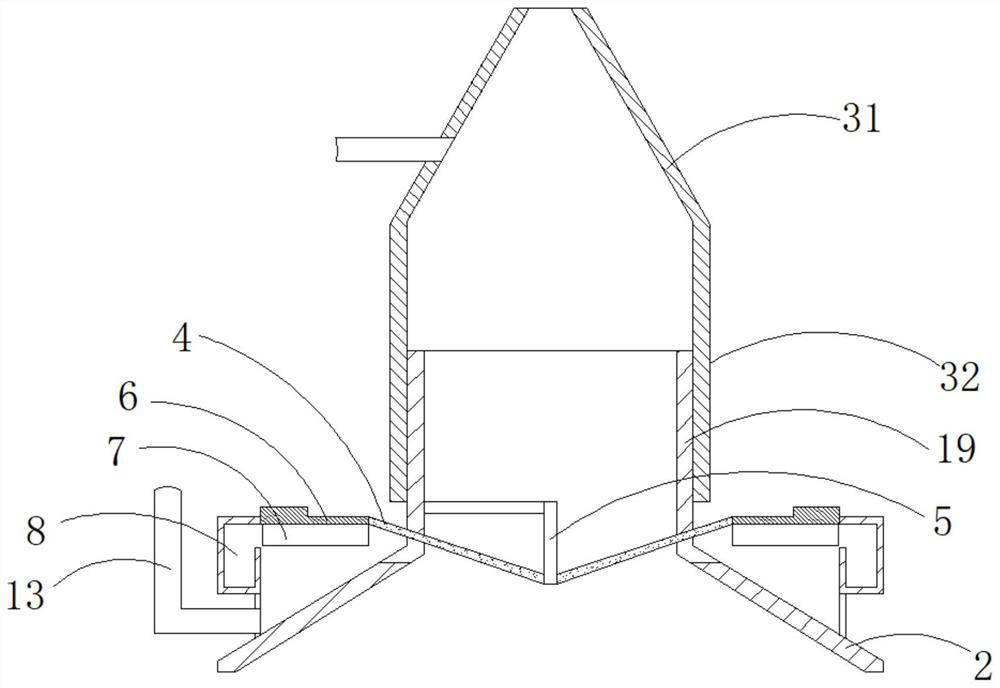

[0047] A kind of cyanobacteria pressurized reuse treatment system based on the air flotation method in embodiment 1 is disclosed in the present embodiment, refer to figure 2 and image 3 , the cyanobacteria pressurized reuse treatment system frame 1 in the present embodiment, the air flotation box 2 and the pressurized cylinder 3 are arranged on the said frame 1, the said pressurized cylinder 3 is located above the air flotation box 2, and the said pressurized The cylinder 3 communicates with the atmosphere.

[0048] Specifically, the air flotation box 2 is fixedly connected with the frame 1, the upper end of the air flotation box 2 is provided with a cylindrical fixed connection part 19, and the pressurized cylinder 3 includes a conical cavity 31 on the upper part and a The lower sliding connection part 32 is in sliding and sealing connection with the fixed connection part 19, and the lifting cylinder 12 for adjusting the position of the pressure cylinder 3 in the vertical ...

Embodiment 3

[0063] In this example, refer to Figure 6 and Figure 7 , and the embodiment 2 is different in that the outer wall of the rotating ring 9 is provided with an outer ring gear and a driven wheel 22 which engage with each other. The driving impeller 24 arranged on the shaft, the inlet pipe 25 and the outlet pipe 26 of the return pipe 13 are biased on the side of the driving impeller 24, the positions of the inlet pipe 25 and the outlet pipe 26 are corresponding, and the inside of the return pipe 13 The liquid enters the inside of the driving disc 23 from the inlet pipe 25, and then comes out from the outlet pipe 26. The liquid can push the driving impeller 24 to rotate, and the driving impeller 24 drives the driven wheel 22 to rotate, and the driven wheel 22 drives the rotating ring 9 and the rotating cover plate 6 Rotate, the driving plate 7 on the bottom surface of the rotating cover plate 6 guides the air bubbles and flocs on the upper surface of the slag sorting box 18, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com