Method for synthesizing lacthydrazide

A technology of lactic hydrazide and hydrazine hydrate, applied in the fields of organic synthesis, pharmaceutical and chemical industry, can solve the problems of high price and non-renewable, and achieve the effect of high-value degradation and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for synthesizing lactohydrazide, the method is as follows:

[0017] (1) Put 10 g of polylactic acid and 30 mL of hydrazine hydrate into a 50 ml reactor. The reactor was heated to 40°C at 6°C / min and kept at 40°C for 12 hours.

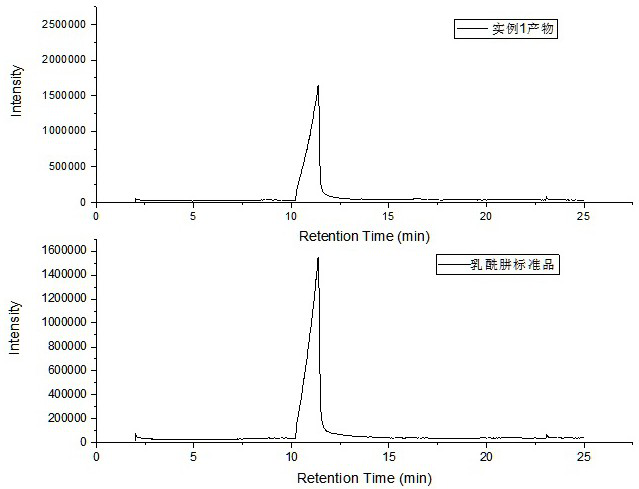

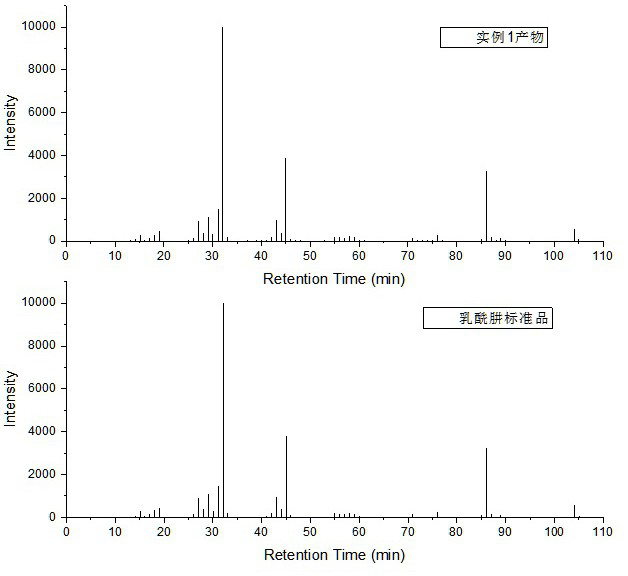

[0018] (2) Cool to room temperature after the reaction to obtain a homogeneous reaction solution; the homogeneous reaction solution was vacuum rotary evaporated at 90° C. to remove the residual hydrazine hydrate solution, and filtered to obtain 13.9 g of a white product. GC-MS analysis of the white product dissolved in methanol (see figure 1 ) and mass spectrometry (see figure 2 ), the product was determined to be lactohydrazide.

Embodiment 2

[0020] A method for synthesizing lactohydrazide, the method is as follows:

[0021] (1) Take 10 g of polylactic acid and 20 mL of hydrazine hydrate in a 50 ml reactor. The temperature of the reactor was raised to 60°C at 6°C / min and kept at 60°C for 12 h.

[0022] (2) Cool to room temperature after the reaction to obtain a homogeneous reaction solution; after quantitative analysis by GC-MS, the solution contains 12.8g of lactohydrazide.

Embodiment 3

[0024] (1) Take 10 g of polylactic acid and 20 mL of hydrazine hydrate in a 50 ml reactor. The reactor was heated to 30°C at 6°C / min and kept at 30°C for 24h.

[0025] (2) Cool to room temperature after the reaction to obtain a homogeneous reaction solution; after quantitative analysis by GC-MS, the solution contains 12.7g of lactohydrazide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com