Low-moisture environment-friendly quenching car for small coke oven, and operation process thereof

A low-moisture, coke-quenching car technology, used in coke ovens, petroleum industry, coke cooling, etc., can solve the problems of affecting the implementation results, threatening the health of operators, and high coke moisture, ensuring occupational health and avoiding excessive moisture. The effect of high and stable coke moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

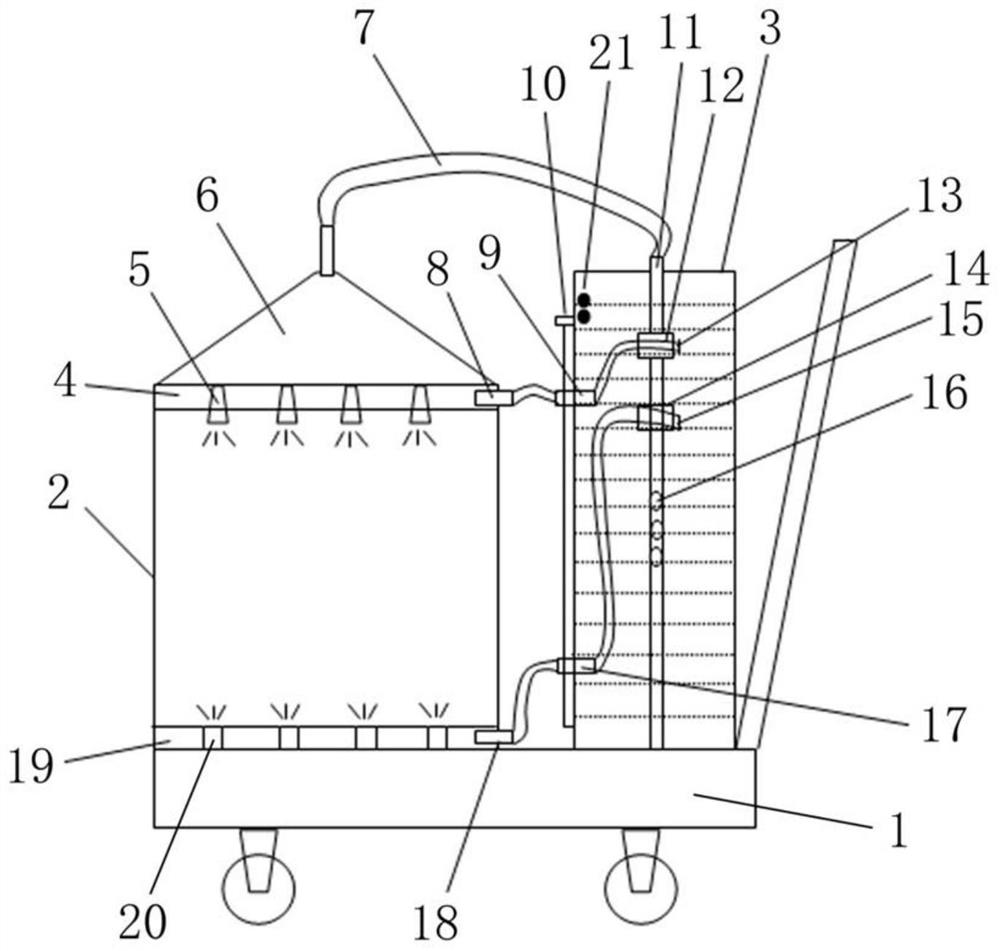

[0025] A low-moisture environment-friendly quenching car for small coke ovens, such as figure 1 As shown, it includes cart 1, coke quenching box 2, water tank 3, water supply pipe 4, atomizing nozzle 5, dust removal cover 6, dust removal hose 7, water supply pipe connection 8, water supply valve 9, water valve switch 10, positioning Rod 11, upper water pipe inlet location 12, upper water pipe hose 13, lower water pipe inlet location 14, lower water pipe hose 15, steam outlet 16, lower water valve 17, lower water pipe interface 18, lower water pipe 19, water outlet hole 20, The coke quenching box 2 and the water tank 3 are arranged side by side on the trolley 1;

[0026] The coke quenching box 2 is a box structure with an upper opening; the upper water pipe 4 is arranged on the top side of the coke quenching box 2 box body, and a plurality of atomizing nozzles 5 are arranged below the body of the upper water pipe 4; One end of the upper water pipe interface 8 extends into the ...

Embodiment 2

[0039] Based on the operation process of the low-moisture environmental protection coke quenching car for small coke ovens described in Example 1, the specific steps are as follows:

[0040] (1) Before connecting the red coke, adjust the water inlet positioning height of the upper water pipe to 10cm below the liquid surface, and adjust the water inlet positioning height of the lower water pipe to 12cm below the liquid surface.

[0041] (2) Put 1000°C red coke into the coke quenching box, cover it with a dust cover, open the upper water valve and the lower water valve at the same time through the water valve switch, and the coke quenching water in the water tank relies on gravity to pass through the upper and lower water pipes, hoses and The atomizing nozzle and water outlet are sprayed on the hot coke, and the steam generated passes through the dust cover, rubber hose and positioning rod, and is discharged into the water tank through the steam outlet for purification.

[0042] (...

Embodiment 3

[0044] Based on the operation process of the low-moisture environmental protection coke quenching car for small coke ovens described in Example 1, the specific steps are as follows:

[0045] (1) Before connecting the red coke, adjust the water inlet positioning height of the upper water pipe to 8cm below the liquid level, and adjust the water inlet positioning height of the lower water pipe to 10cm below the liquid surface.

[0046] (2) Put 1000°C red coke into the coke quenching box, cover it with a dust cover, open the upper water valve and the lower water valve at the same time through the water valve switch, and the coke quenching water in the water tank relies on gravity to pass through the upper and lower water pipes, hoses and The atomizing nozzle and water outlet are sprayed on the hot coke, and the steam generated passes through the dust cover, rubber hose and positioning rod, and is discharged into the water tank through the steam outlet for purification.

[0047] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com