Splicing assembly type building concrete prefabricated part

A prefabricated concrete, prefabricated technology, applied in construction, building materials, building structures, etc., can solve the problems of reducing labor, inconvenient work for operators, affecting the service life of prefabricated concrete, etc., and achieving the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

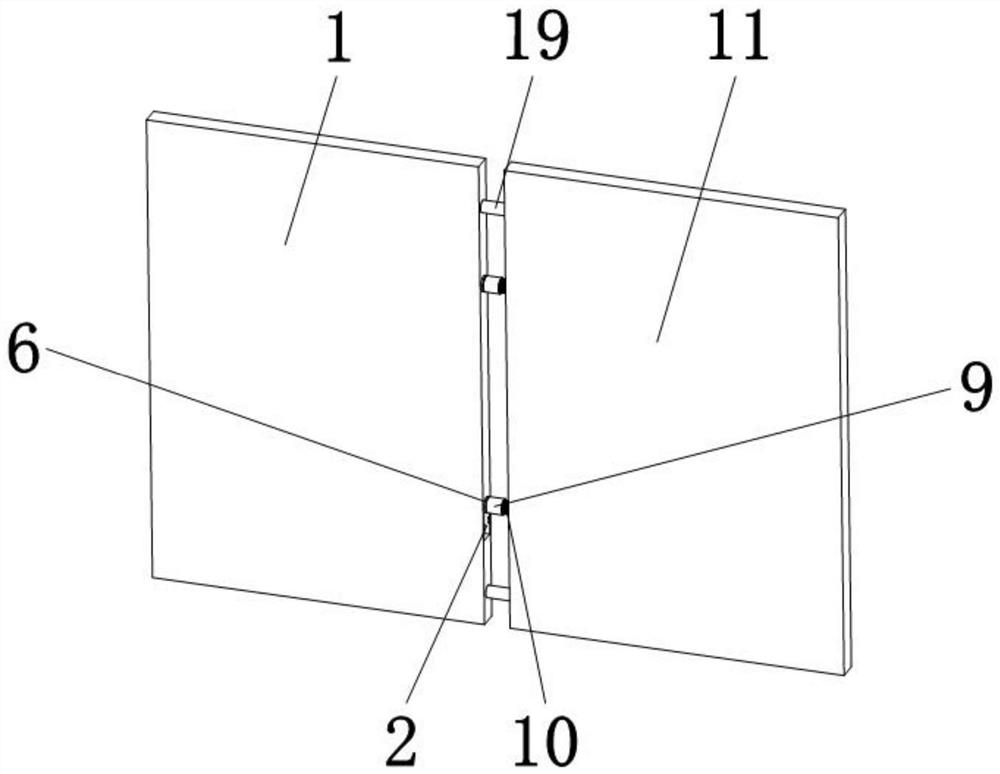

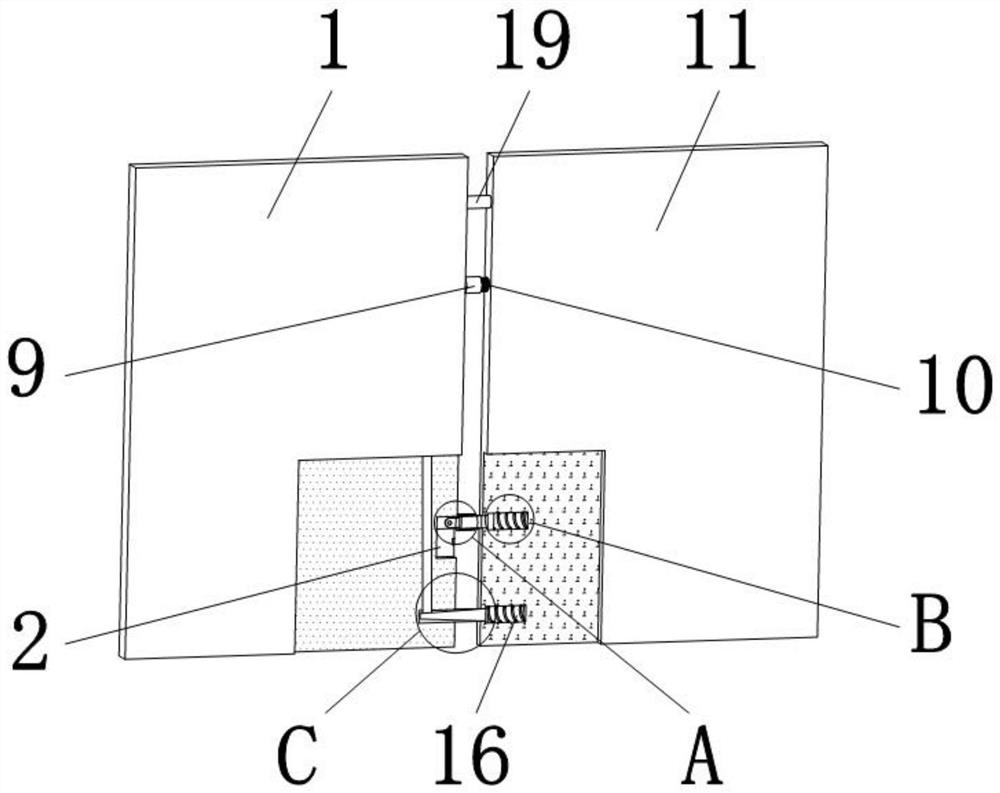

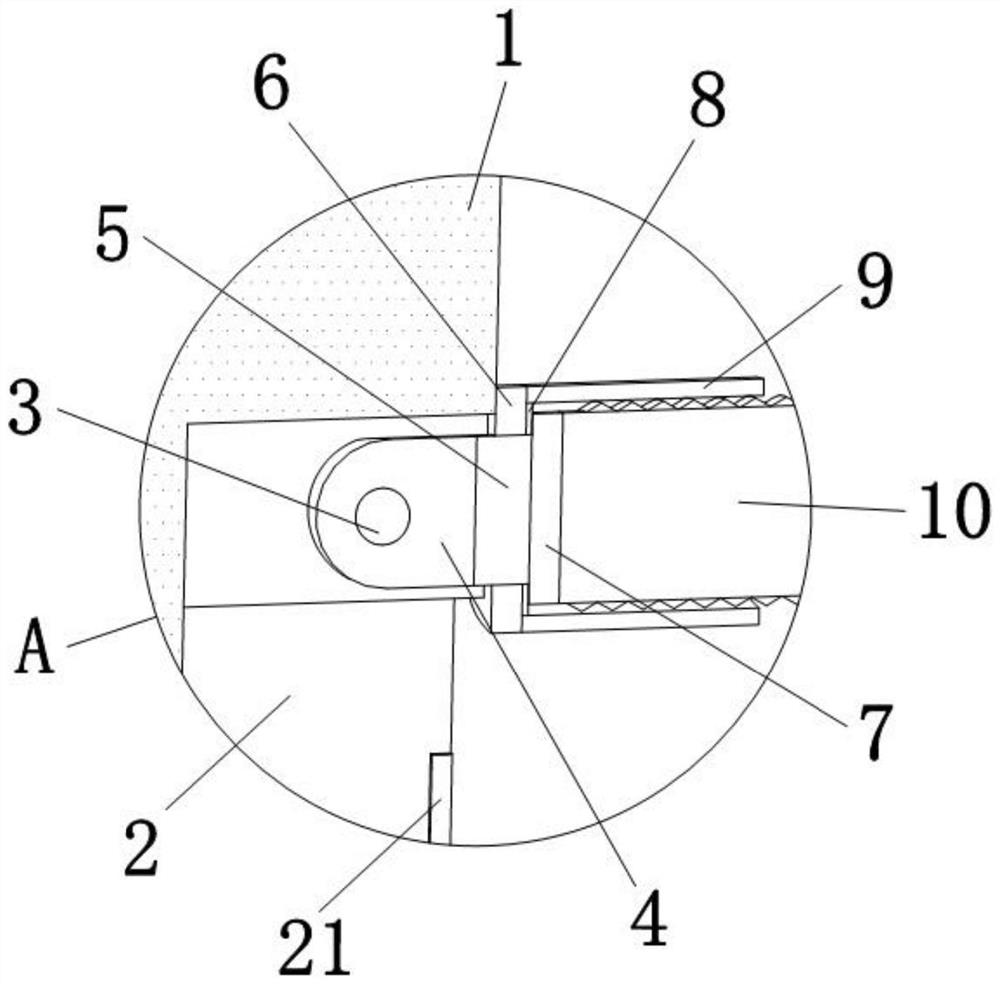

[0036] Such as Figure 1 to Figure 5 As shown, the present invention provides a spliced and assembled building concrete prefabricated part, including a main board 1, the upper and lower ends of the right side of the main board 1 are provided with a fixing groove 2, and the top of the inner cavity of the fixing groove 2 is fixedly sleeved with a fixed shaft 3, which is fixed The outer surface of the shaft 3 is movably socketed with a rotating block 4, one side of the rotating block 4 is provided with a connecting device, and one side of the connecting device is provided with a threaded sleeve 9, and the connecting device includes a connecting block 5, and the connection between the connecting block 5 and the rotating block 4 One side is fixedly connected, the outer surface of the connecting block 5 is movably sleeved with a fixed block 6, one side of the fixed block 6 is fixedly connected with the threaded sleeve 9, the right end of the connecting block 5 is provided with an a...

no. 2 example

[0044] Based on the splicing and assembly type prefabricated building concrete parts provided by the first embodiment, the splicing of the main board 1 and the sub-board 11 is mainly carried out by using the threaded fitting method of the threaded rod 10 and the threaded sleeve 9, so manual work is required during assembly. Twist the threaded rod 10 between the sub-plates 11, but in actual use, this operation process will cause a gap between the main board 1 and the sub-plate 11, thereby reducing the splicing tightness and aesthetics of the concrete prefabricated parts. In order to solve this problem, Ensure that there is no gap between the main board 1 and the sub-board 11 in actual use, combined with Figure 6-8 , the spliced and assembled building concrete prefabricated part also includes: the first installation block 14 is provided with feed teeth, the first installation block 14 can drive the thread teeth 10 to rotate and feed, and the middle part of the sub-plate 11 is ...

no. 3 example

[0051]Based on the spliced and assembled building concrete prefabricated parts provided by the second embodiment, the tight fixation between the components can be realized in actual use, but in special cases such as earthquakes and strong winds, the main board 1 and the sub-board 11 will follow. Shaking will eventually cause damage. Therefore, in order to solve the problem of shock absorption of the device, the original tight fixed connection method is released by means of the cooperation and linkage of various parts during the shaking process, and converted into an elastic matching method between the parts, thereby improving the device. Therefore, this kind of spliced and assembled building concrete prefabricated part also includes: one side of the notch 22 is provided with a lead pendant groove 32, the top of the lead pendant groove 32 is provided with a sling 33, and the bottom of the sling 33 is provided with a Lead pendant 34, the tensile performance of sling 33 is cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com