A solid rocket motor free-filling grain-pressing structure and using method

A technology of solid rockets and motors, which is applied in the direction of rocket motor devices, machines/engines, mechanical equipment, etc. It can solve the problems of abnormal internal ballistics and spring falling off, and achieve the effect of simple structure, not easy to fall off, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

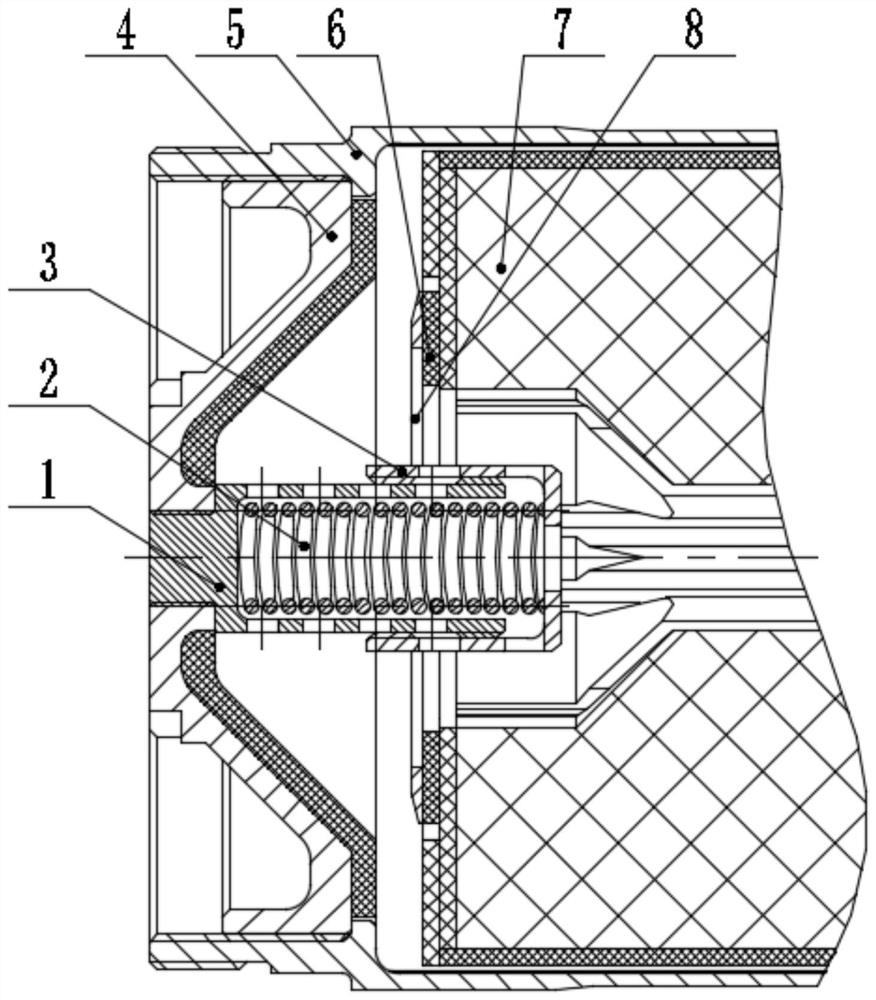

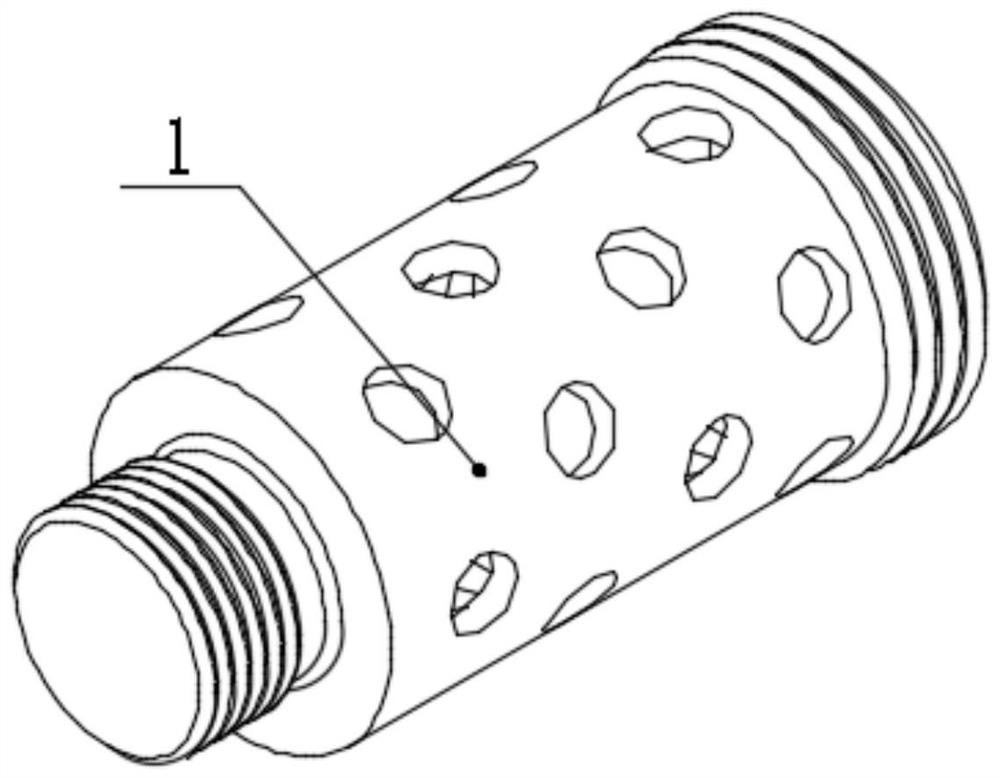

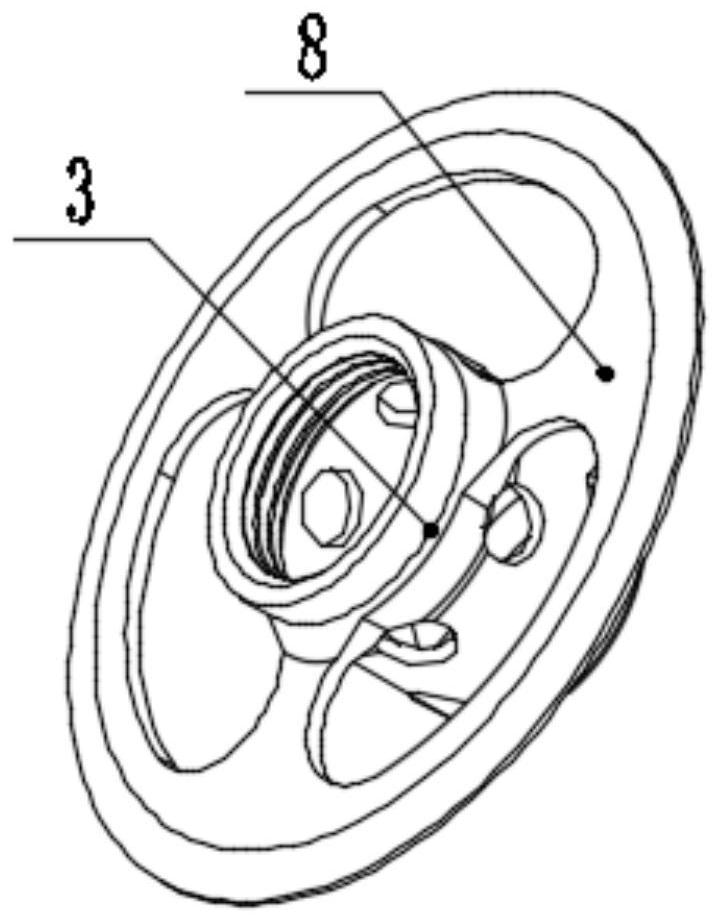

[0025] like Figures 1 to 3 As shown in the figure, the present embodiment provides a solid rocket motor free-filling grain compression structure, including a combustion chamber 5, and the combustion chamber 5 is sequentially provided with a blocking cover 4, a conduit 1, and a grain compression ring 3 from left to right. And free-filling powder column 7, a drug pressing spring 2 is arranged in the conduit 1, one end of the conduit 1 is threadedly connected with the blocking cover 4, and the other end is slidably connected with the drug column pressing ring 3.

[0026] The use process of the present invention is as follows:

[0027] Put the medicine compression spring 2 in the catheter 1, and the medicine column compression ring 3 compresses the medicine compression spring 2 and screwed into the catheter 1 until the medicine column compression ring 3 is sheathed outside the catheter 1 and moves freely. Next, screw the conduit 1 into the central thread of the cap 4 . Finally,...

Embodiment 2

[0029] The right end of the catheter 1 is provided with an external thread, the left end of the drug column pressing ring 3 is provided with an internal thread matching the external thread, and the inner wall of the drug column pressing ring 3 on the right side of the internal thread is a smooth surface.

[0030] After the grain compression ring 3 is screwed into the outer thread of the catheter 1, it can be sleeved on the catheter 1 and move freely, and at the same time, it will not fall off due to the resistance of the thread. This also ensures that the grain compression ring 3 can move freely with the deformation of the grain compression spring 2 and the grain and has a certain pre-tightening force.

[0031] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0033] The side wall of the catheter 1 is provided with a number of first ventilation holes, the first ventilation holes communicate with the inner cavity of the blocking cover 4, and the right end face and the side wall of the grain compression ring 3 are provided with a number of second ventilation holes, and the grain pressure The outer surface of the tightening ring 3 is provided with a medicine pressing surface 8 specially used for pressing the freely packed grain 7 . The first vent hole communicates with the second vent hole, and the second vent hole communicates with the free-filling grain column 7 .

[0034] The first vent hole and the second vent hole are provided mainly to facilitate the circulation of gas.

[0035] Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com