Efficient heat dissipation battery pack structure

A battery pack, high-efficiency technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of less cycle times, low energy density ratio, poor heat dissipation, etc., and achieve the effect of improving heat transfer and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

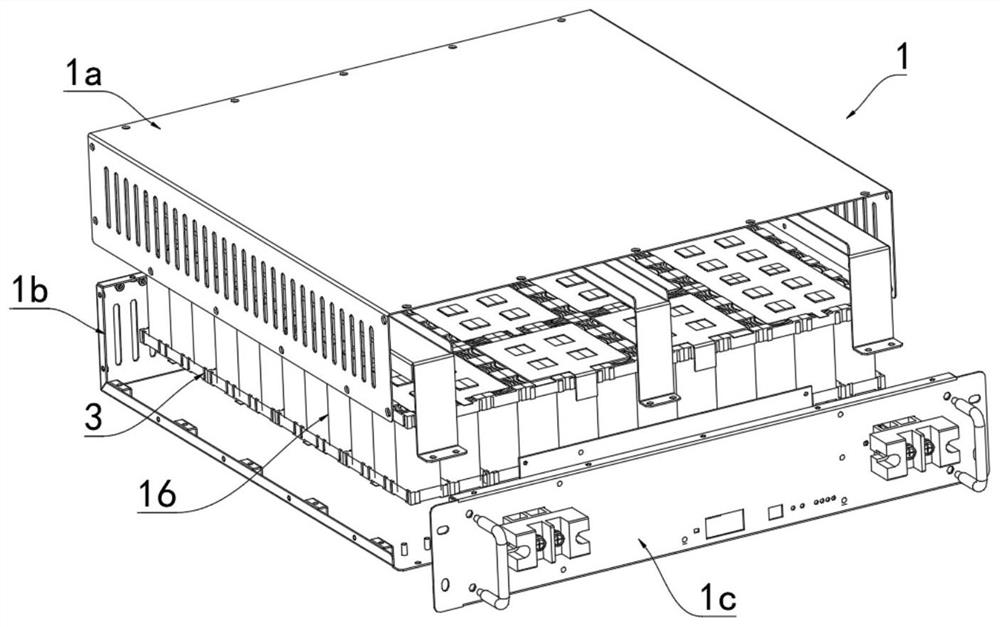

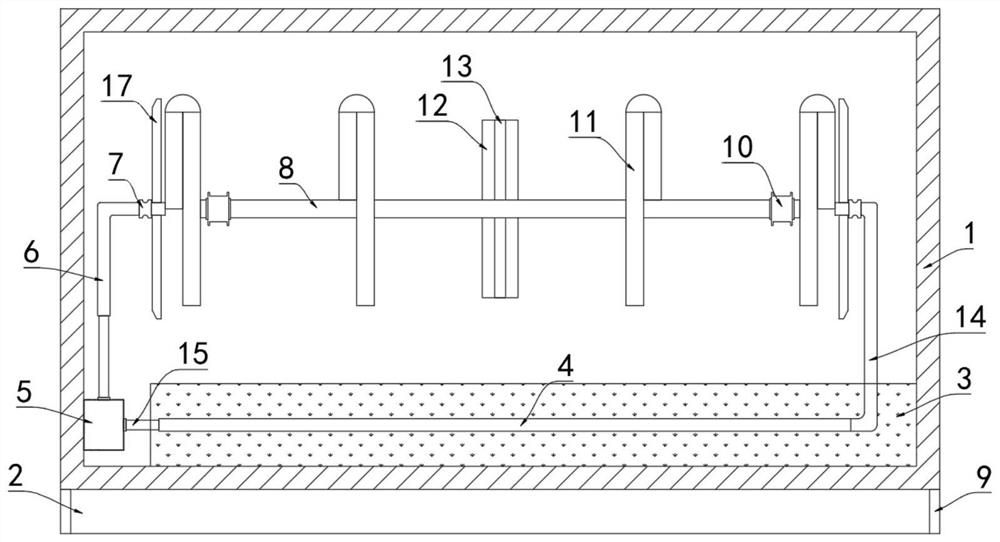

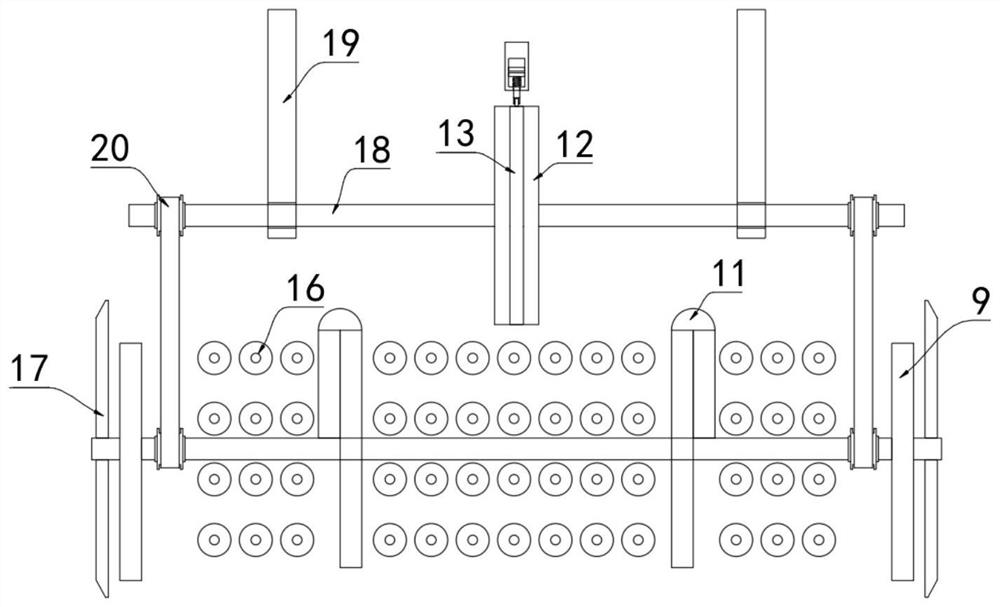

[0029] refer to Figure 1-6 , a high-efficiency heat dissipation battery pack structure, including a battery box 1, wherein the battery box 1 includes an upper box cover 1a, a lower box body 1b, and a panel 1c, and the upper box cover 1a, lower box body 1b, and panel 1c are composed of two pairs are connected by bolts, and a positive terminal and a negative terminal are installed on the panel 1c, then a positive current collector and a negative current collector corresponding to the positive terminal and the negative terminal are installed on the battery pack 16 .

[0030] The inner bottom of the battery box 1 is equipped with a thermally conductive silica gel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com