Composite membrane with heterostructure separation layer and preparation method of composite membrane

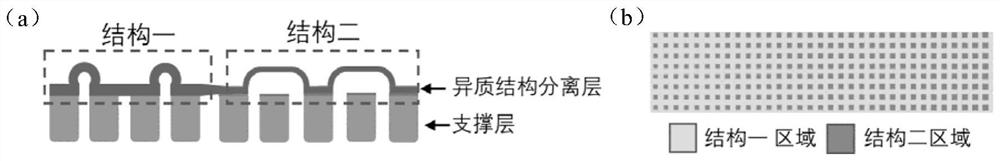

A technology of heterostructure and separation layer, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem that the spatial distribution of permeability of composite membrane is difficult to control accurately, and achieve precise control of size and spatial distribution. , to improve flexibility and controllability, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

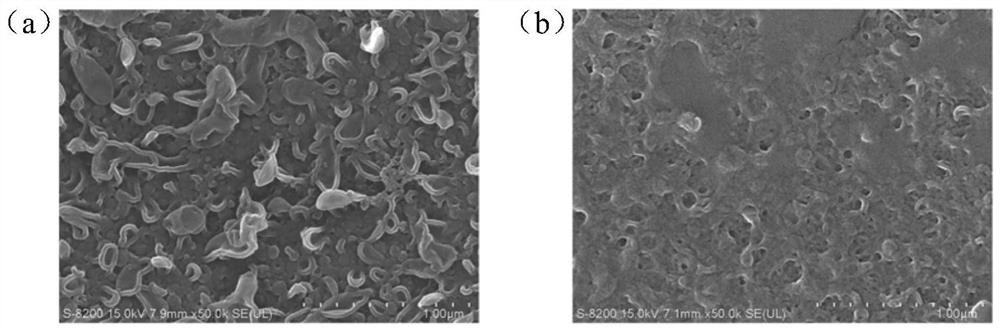

Method used

Image

Examples

Embodiment 1

[0052] This embodiment 1 provides a method for preparing a composite membrane with a heterogeneous structure separation layer, comprising the following steps:

[0053] (1) m-phenylenediamine is dissolved in water to obtain the first aqueous phase solution, and the mass concentration of m-phenylenediamine is 2%;

[0054] (2) Soak five pieces of polysulfone ultrafiltration basement membranes in the first aqueous phase solution, take them out after soaking for 1 minute, and dry the residual aqueous phase solution on the surface with an air knife;

[0055] (3) Dissolving piperazine in water to obtain a second aqueous phase solution, and adding it to a blank ink cartridge of an inkjet printing device as printing ink, the mass concentration of piperazine is 0.1%;

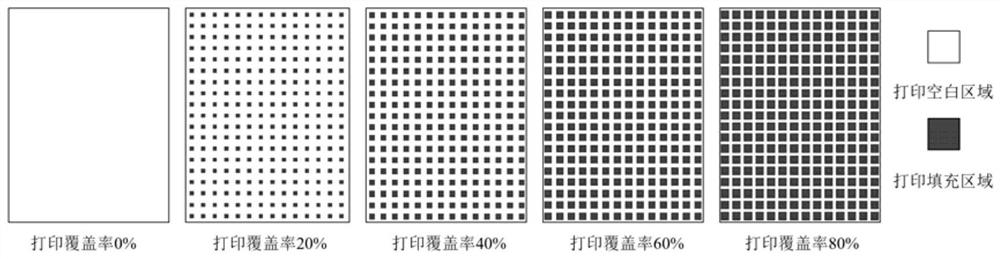

[0056] (4) if figure 2 As shown, design 5 checkerboard printing patterns, in which the proportions of filled areas are 0%, 20%, 40%, 60% and 80% respectively, and are obtained in step (2) according to the designed patte...

Embodiment 2

[0064] This embodiment 2 provides a method for preparing a composite membrane with a heterogeneous structure separation layer, comprising the following steps:

[0065] (1) Dissolve tannic acid and ferric chloride hexahydrate in deionized water to form tannic acid-iron complex intermediate layer precursor solution, and add it to the blank ink cartridge of inkjet printing equipment as printing ink, tannic acid and The mass concentration of ferric chloride hexahydrate is 0.1%;

[0066] (2) Design 5 checkerboard printing patterns, in which the proportion of filling area is 0%, 20%, 40%, 60% and 80% respectively; by inkjet printing according to the designed pattern in the polyethersulfone ultrafiltration The base film surface spraying step (1) described intermediate layer precursor liquid, forms 5 base films with patterned intermediate layer and intermediate layer coverage different, wherein the spraying position of precursor liquid depends on the position of printing pattern filli...

Embodiment 3

[0076] This embodiment 3 provides a method for preparing a composite membrane with a heterogeneous structure separation layer, comprising the following steps:

[0077] (1) disperse graphene oxide in deionized water to form an intermediate layer precursor, and add it to a blank ink cartridge of an inkjet printing device as printing ink, and the mass concentration of graphene oxide is 0.2%;

[0078] (2) Refer to Figure 4 , design a printing pattern in which the proportion of the filling area gradually changes from 5% to 95% along the lateral direction, and print the intermediate layer precursor solution described in step (1) onto the surface of the polyacrylonitrile ultrafiltration base membrane with a length of 1 meter according to the pattern, wherein The spraying position of the precursor liquid depends on the position of the printed pattern filling area;

[0079] (3) ethylenediamine is dissolved in water to obtain an aqueous phase solution of ethylenediamine, and the mass ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap