Flat plate type two-stage centrifugal machine

A centrifuge and flat-plate technology, applied in centrifuges, centrifuges with rotating drums, etc., to eliminate resonance phenomena, improve quality and effect, and achieve good removal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

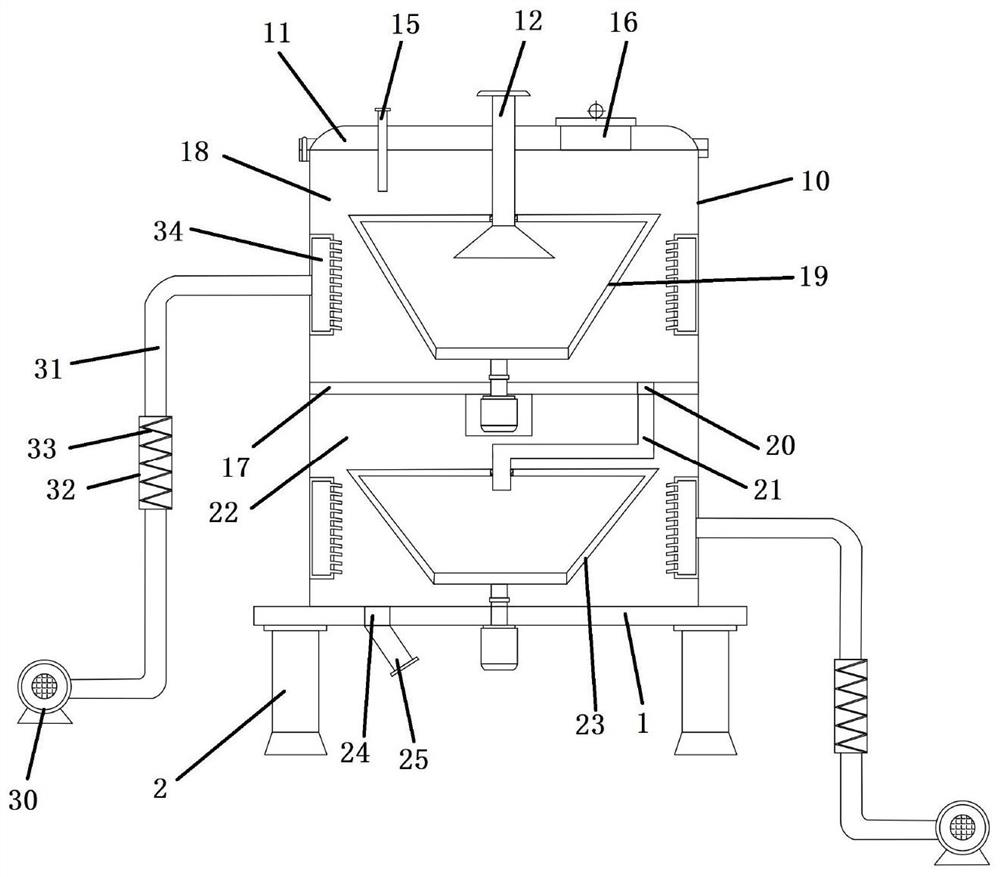

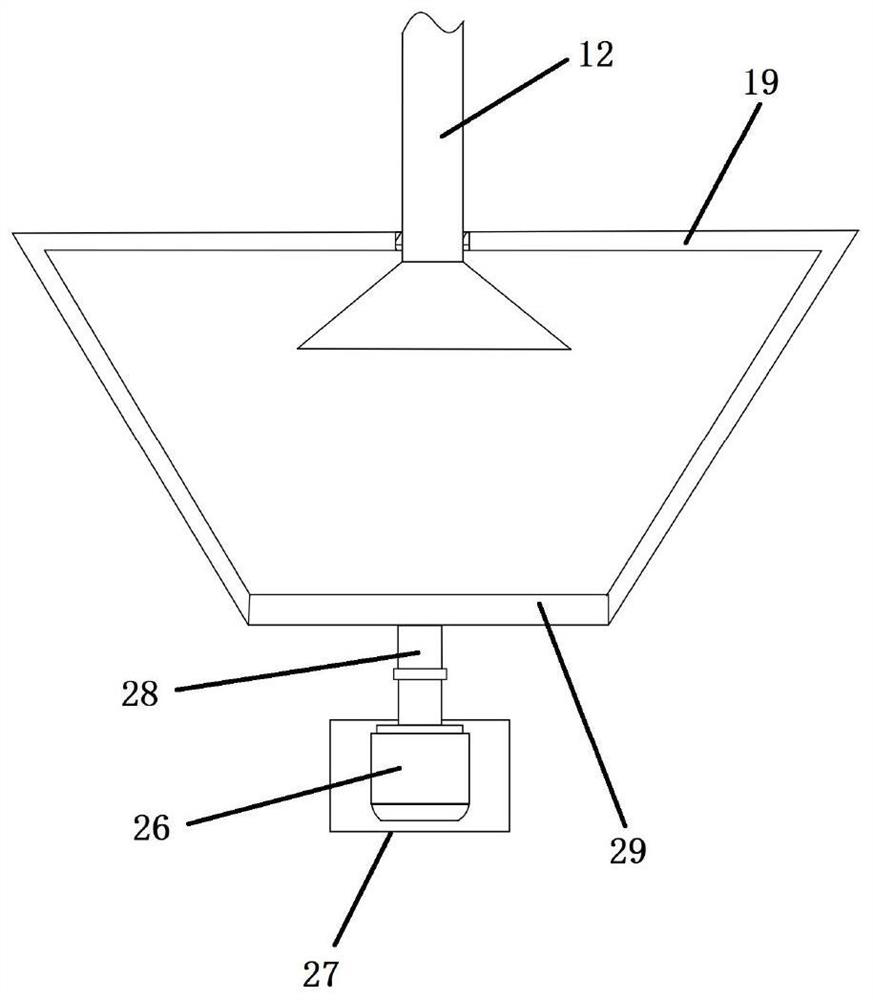

[0024] Embodiments of the present invention disclose a flat-plate double-stage centrifuge, such as figure 2 As shown, it includes a machine base 1, a casing 10, a partition plate 17, an upper cover 11 and a shock absorbing device 2. Vibration device 2, casing 10 top opening is provided with loam cake 11, loam cake 11 is provided with feed pipe 12, loam cake 11 is also provided with washing pipe 15 and observation hole 16, and dividing plate 17 is horizontally fixedly arranged on Inside the casing 10, it is divided into a first-level separation chamber 18 and a second-level separation chamber 22; the first-level separation chamber 18 is provided with an inverted cone-shaped first filter screen 19, and the first filter screen 19 is used to drive its The rotating first driving device is connected, and the top of the first filter screen 19 is provided with a first feeding port, and the lower end of the feeding pipe 12 is connected with the first feeding port in rotation and exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com