Valve control device

A valve control and valve technology, applied in the field of valve control devices, can solve problems such as safety accidents, pipeline transformation, and complex transformation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

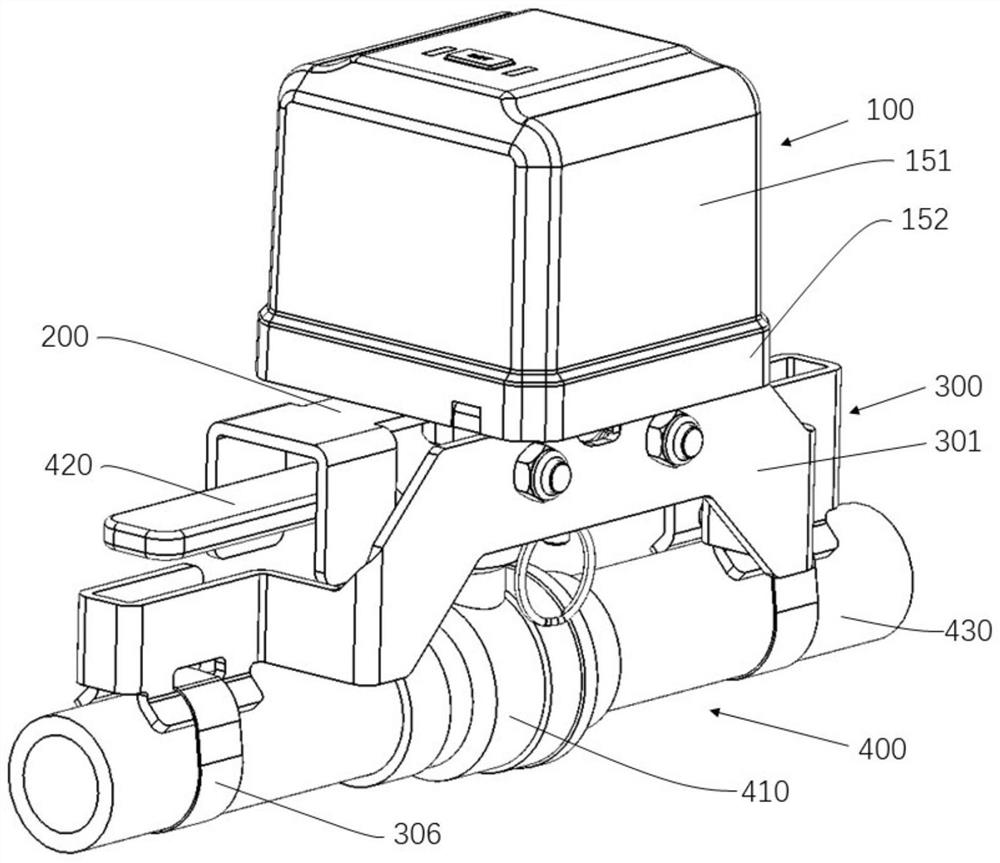

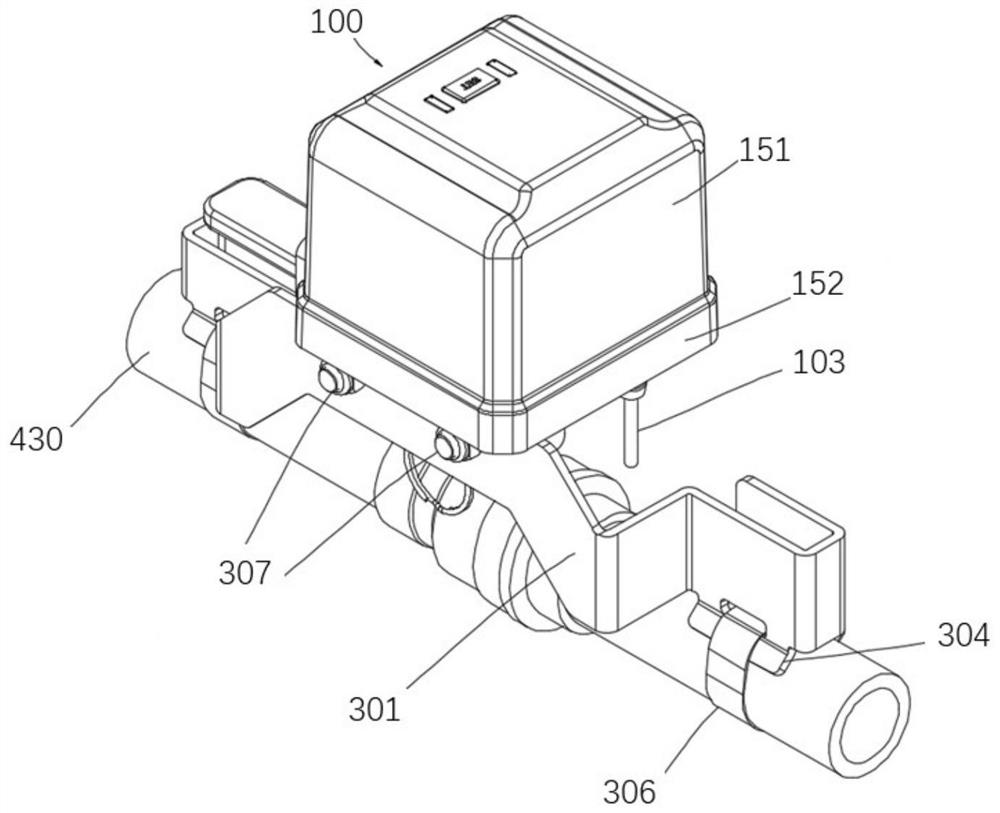

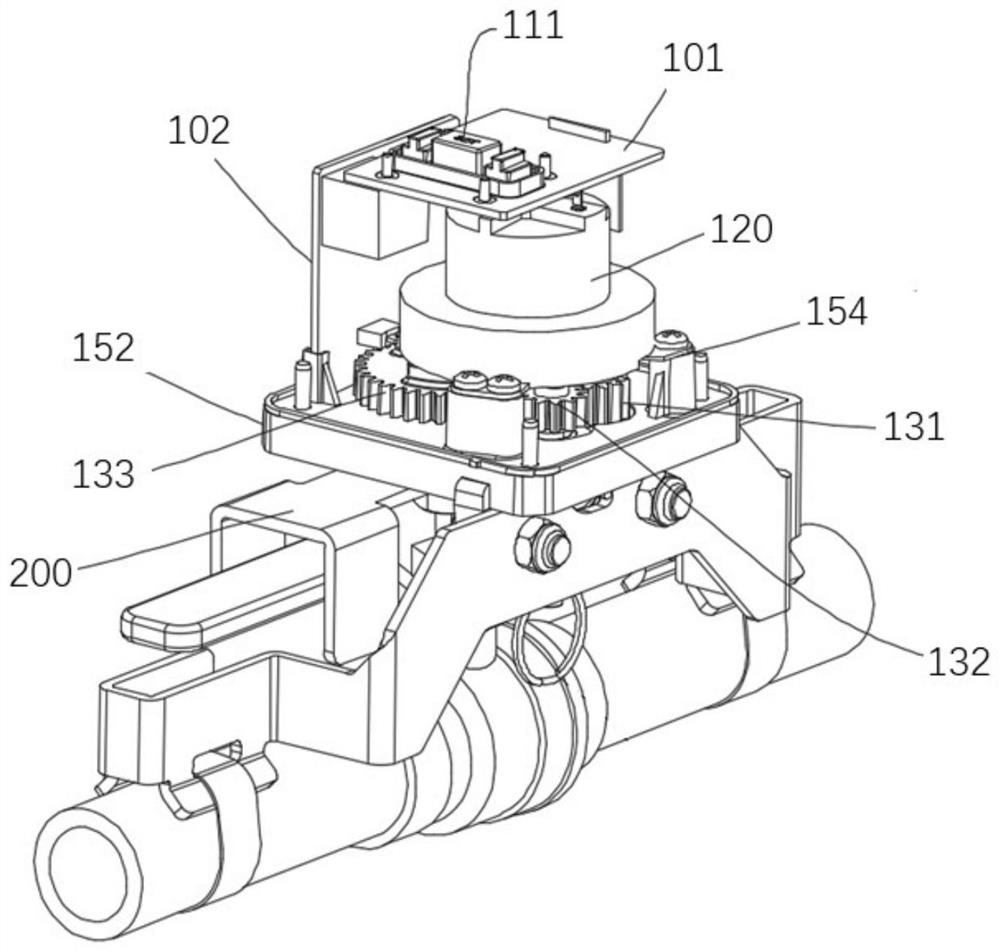

[0084] Such as figure 1 and figure 2 As shown, this embodiment provides a valve control device, including a control unit 100 , a first actuator 200 and a fixing mechanism 300 . The first actuator 200 is connected to the control part 100 , the control part 100 is fixed on the fixing mechanism 300 , and the fixing mechanism 300 is fixed on the valve assembly 400 . Wherein, the valve assembly 400 is an existing structure, including a valve 410, a handle 420 for controlling the valve 410, and a pipeline 430 connected to the valve 410. The pipeline 430 can be a pipeline for allowing water or gas to flow through. By manually rotating the handle 420 , the valve 410 can be opened and / or closed. The first actuator 200 is attached to the handle 420 , and the control unit 100 can control the movement of the first actuator 200 according to the received signal, and then the first actuator 200 drives the handle 420 to automatically open or close the valve 410 . The control part 100 and ...

Embodiment 2

[0109] Figure 15-Figure 20 Example 2 is shown. Compared with Embodiment 1, this embodiment differs only in the structure in which the actuator is attached to the handle 420 and the structure in which the bracket is fixed to the pipe 430 . Therefore, only the differences from Embodiment 1 will be described here.

[0110] In Embodiment 1, the first actuator 200 can only be attached to a handle of a specific size, and cannot be adapted to handles of different sizes. In order to solve this problem, in this embodiment, an adjustment mechanism is provided on the second actuator 210 . The adjustment mechanism includes a locking portion 213 , a first sliding block 215 and a second sliding block 225 . The first sliding block 215 is "L"-shaped, including a first sliding portion 216 and a first blocking portion 217, and a first slide groove 218 is obliquely arranged on the first sliding portion 216; A sliding blocking piece 215 has a similar structure, including a second sliding portio...

Embodiment 3

[0113] Figure 21 and Figure 22 Embodiment 3 is shown, compared with embodiment 1, the difference is only in the structure of the attachment of the actuator to the handle 420 .

[0114] Such as Figure 21 As shown, the fixing mechanism 300 includes a third bracket 331 and a fastening seat 340 separated from the third bracket 331 . Both ends of the third bracket 331 are respectively provided with second fixing parts, specifically, the second fixing parts of the third bracket 331 are configured as inserting pieces 332 . The fastening seat 340 includes a fourth “V”-shaped fastening surface 341 fitted with the pipe 430 , a through hole for passing through the second fastening belt 343 , and a slot 342 for inserting the insertion piece 332 . During installation, two identical fastening seats 340 are respectively fastened on the pipe 430 through the second fastening belt 343, and the positions of the two fastening seats 340 are corresponding to the two insertion pieces 332 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com