Contact pin and socket

A contact pin and contact terminal technology, applied in electronic circuit testing, measuring devices, instruments, etc., can solve the problems of hollow processing of upper contact members, lower yield, and inability to properly accommodate springs, etc., to shorten the overall length and take into account the durability. Sexual and mass-producible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in this specification, for the sake of convenience, the central axis of the contact pins is vertical, and the first needle head is arranged on the upper side, and the second needle head is arranged on the lower side. However, the way of disposing the contact pins and the socket including the contact pins is of course not limited to this way.

[0074]

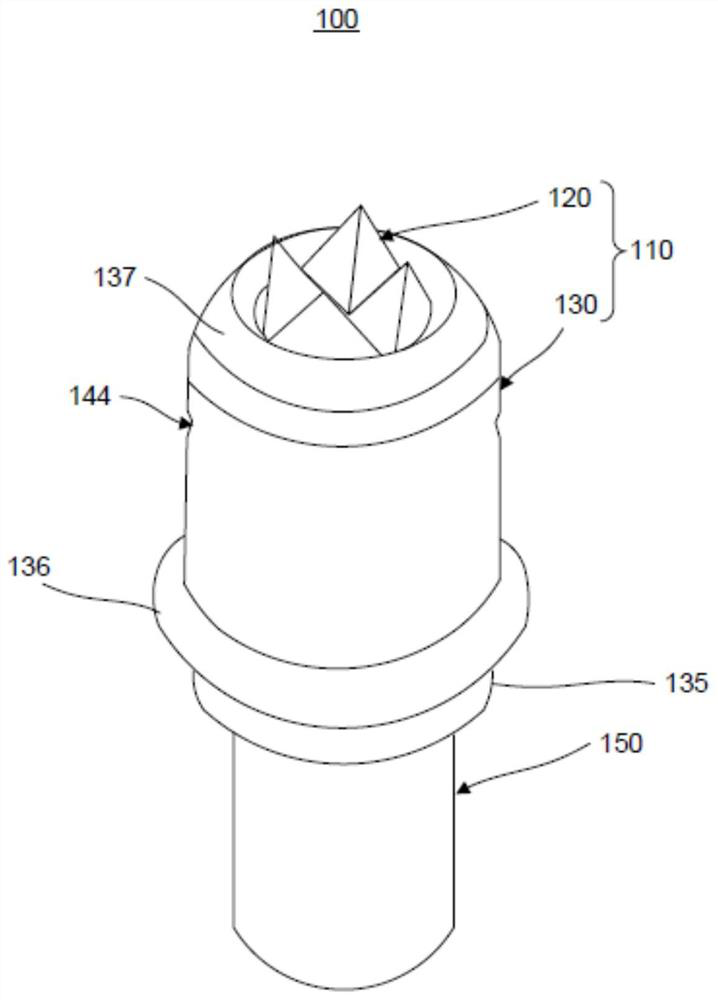

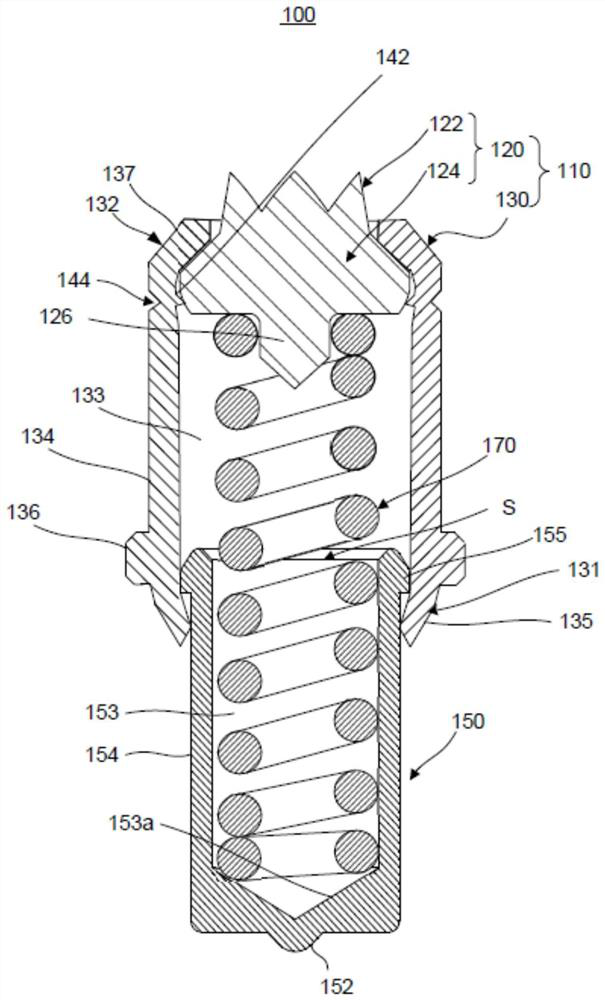

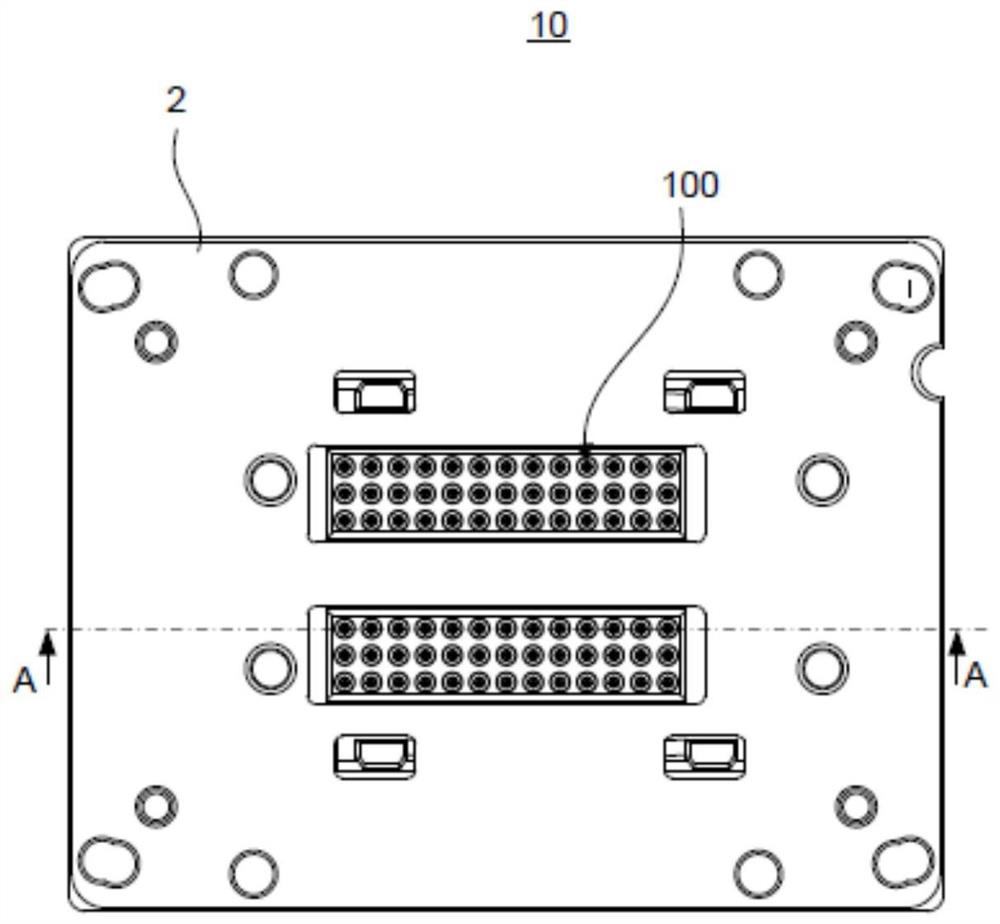

[0075] figure 1 is an external perspective view of the contact pin 100 in the non-use state according to the embodiment of the present invention, figure 2 It is a longitudinal sectional view explaining the structure of the main part of this contact pin.

[0076] figure 1 and figure 2 The illustrated contact pins 100 electrically connect the first electrical component and the second electrical component.

[0077] The contact pin 100 includes a first needle 110 contacting the first electrical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com