Bean cake making machine

A machine and bean cake technology, which is applied in the field of bean cake making machines, can solve the problems of low work efficiency, low manpower consumption, low bean cake work efficiency, and large manpower consumption, so as to improve production efficiency, prevent excessive production speed, and reduce manpower the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A bean cake making machine, such as figure 1 As shown, it includes a bottom plate 1, a motor base 2, a horizontal motor 3, a conveying mechanism 4 and a filling mechanism 5, the upper side of the front of the bottom plate 1 is provided with a motor base 2, and the upper side of the motor base 2 is equipped with a horizontal motor 3, and the bottom plate 1 The front part is provided with a conveying mechanism 4, which is connected to the output shaft of the horizontal motor 3, and the bottom plate 1 is provided with a filling mechanism 5, which cooperates with the conveying mechanism 4.

[0069]When people prepare to make bean cakes, the raw materials are first poured into the filling mechanism 5, and now the template is put into the conveying mechanism 4, and the horizontal motor 3 is started at this moment, and the conveying mechanism 4 will drive the template to move backwards. When the template moves to the lower side of the filler mechanism 5, the filler mechanism 5...

Embodiment 2

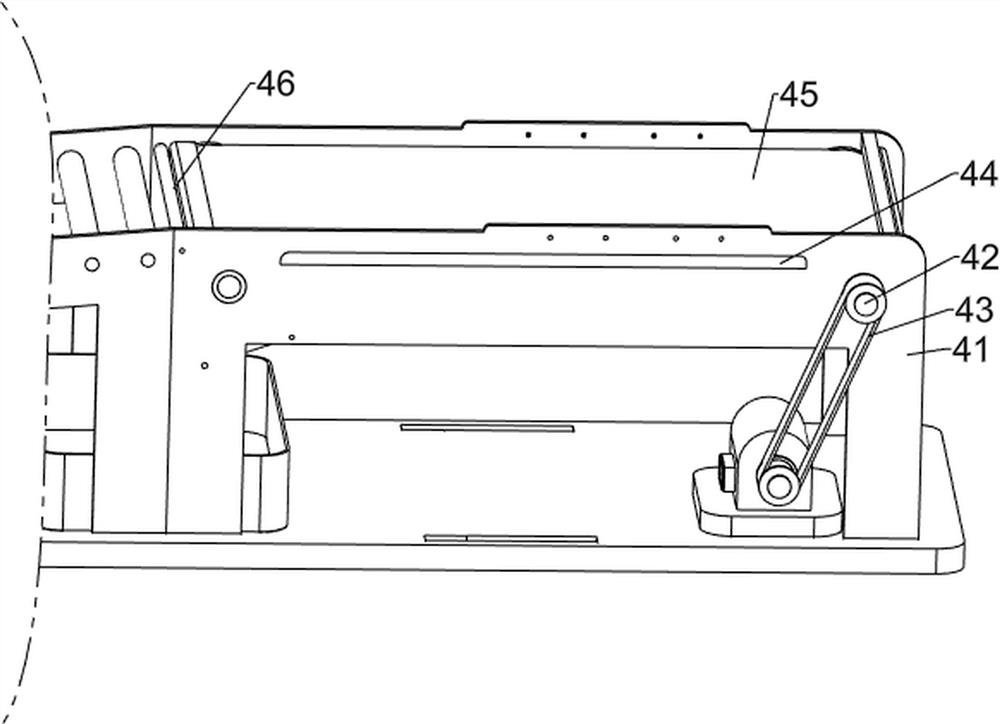

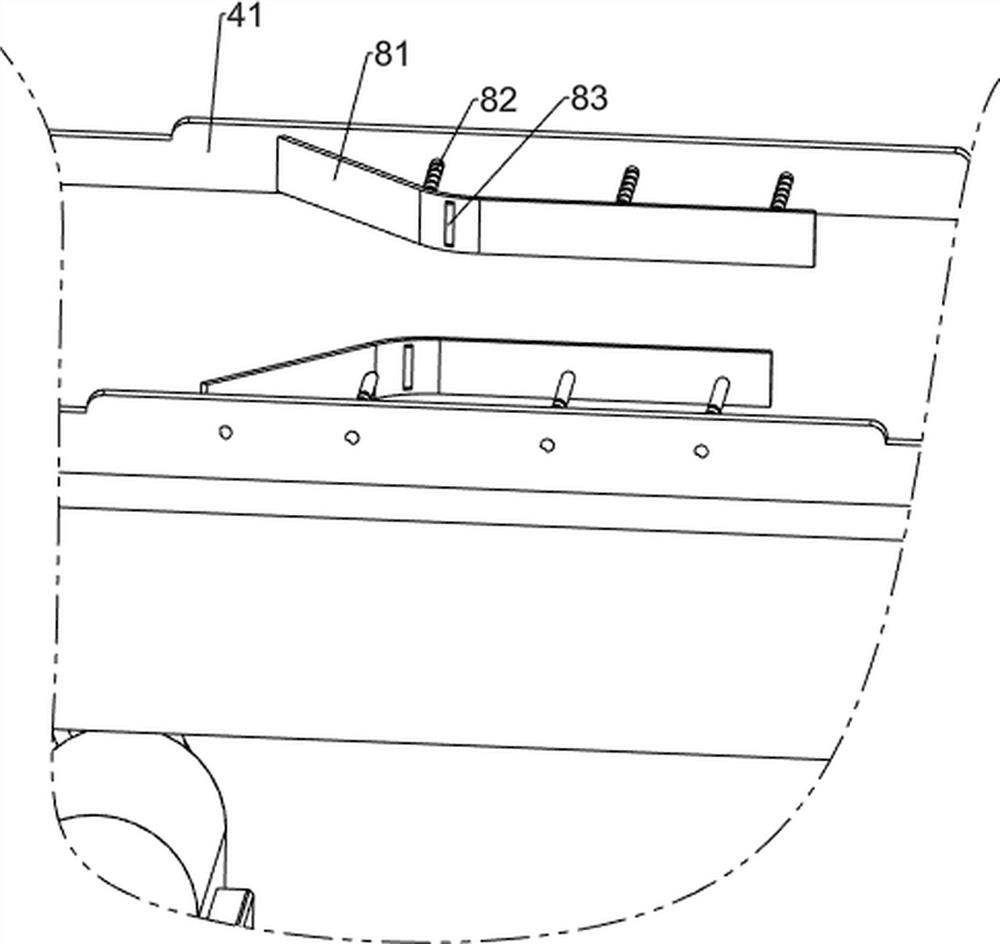

[0071] On the basis of Example 1, such as figure 2 with image 3 As shown, the conveying mechanism 4 includes a first support plate 41, a belt shaft 42, a first belt 43, a reinforcement plate 44, a second belt 45 and a first roller 46, and two first support plates are arranged on the upper side of the front part of the bottom plate 1. Plate 41, the first support plate 41 top rotation type is provided with two belt shafts 42, the left side of the belt shaft 42 of the front part is connected with the output shaft of the horizontal motor 3 with the first belt 43, the belt shafts 42 on the front and rear sides A second belt 45 is wound on the top, and a reinforcing plate 44 is provided on the upper side of the first supporting plate 41 on the left and right sides, and the reinforcing plate 44 cooperates with the second belt 45. The first roller 46 .

[0072] When people prepare to make bean cake, first raw material is poured in the filling mechanism 5, template is put into on t...

Embodiment 3

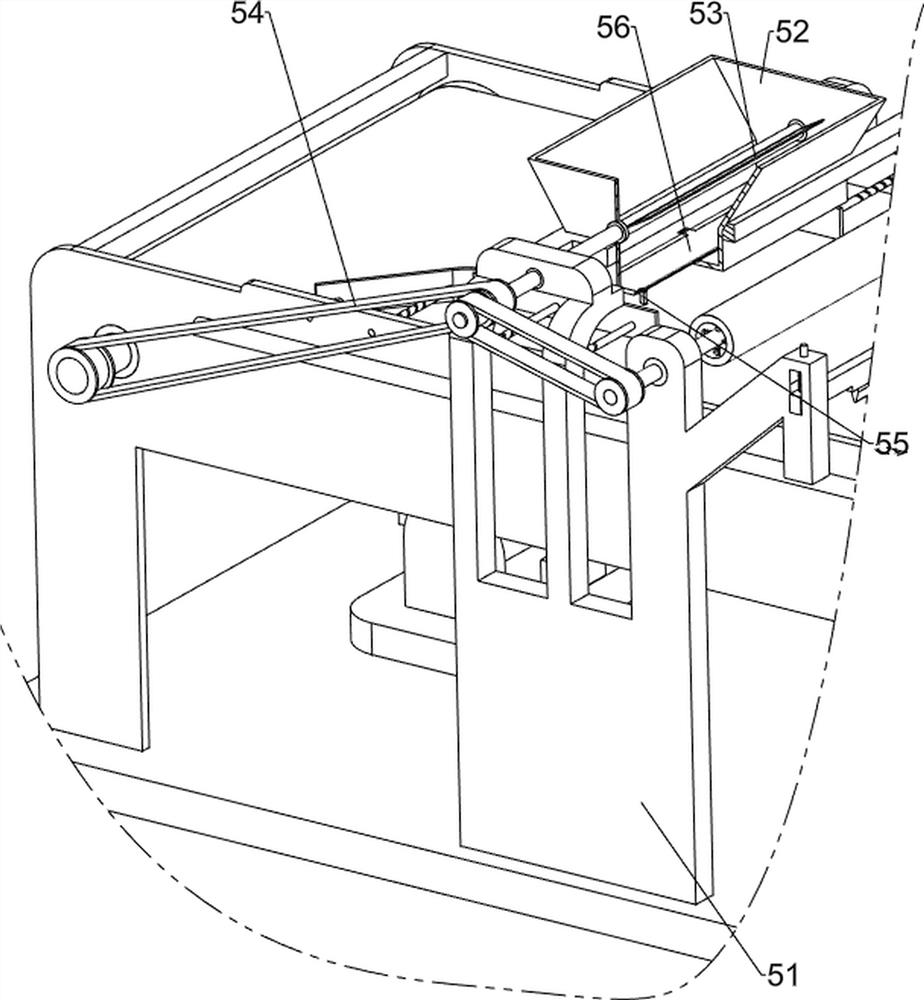

[0076] On the basis of Example 2, such as Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, it also includes an extruding mechanism 6, and the extruding mechanism 6 includes a first bearing 61, a first cylinder 62, a first spring 63, a round tube 64, a third belt 65 and a pulley 66, and the upper part of the second support plate 51 The inner side is provided with a first bearing 61, the first bearing 61 is provided with a first cylinder 62, the first cylinder 62 is connected with a plurality of first springs 63, the outside of the first spring 63 is provided with a round tube 64, and the first cylinder 62 is on the right side. Side and rotating plate 53 right sides are all provided with pulley 66, and the 3rd belt 65 is wound on the pulley 66 of front and back both sides.

[0077] When people are ready to make bean cakes, the raw materials are first poured into the first hopper 52, and the template is put on the second belt 45. At this time, the horizon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap