Multi-sorting type garbage and waste recovery equipment in building construction

A technology for construction and waste, which is applied in the field of waste and waste recycling equipment in construction, and can solve the problems of waste of resources, inaccurate operation effects, and consumption of human resources for manual sorting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

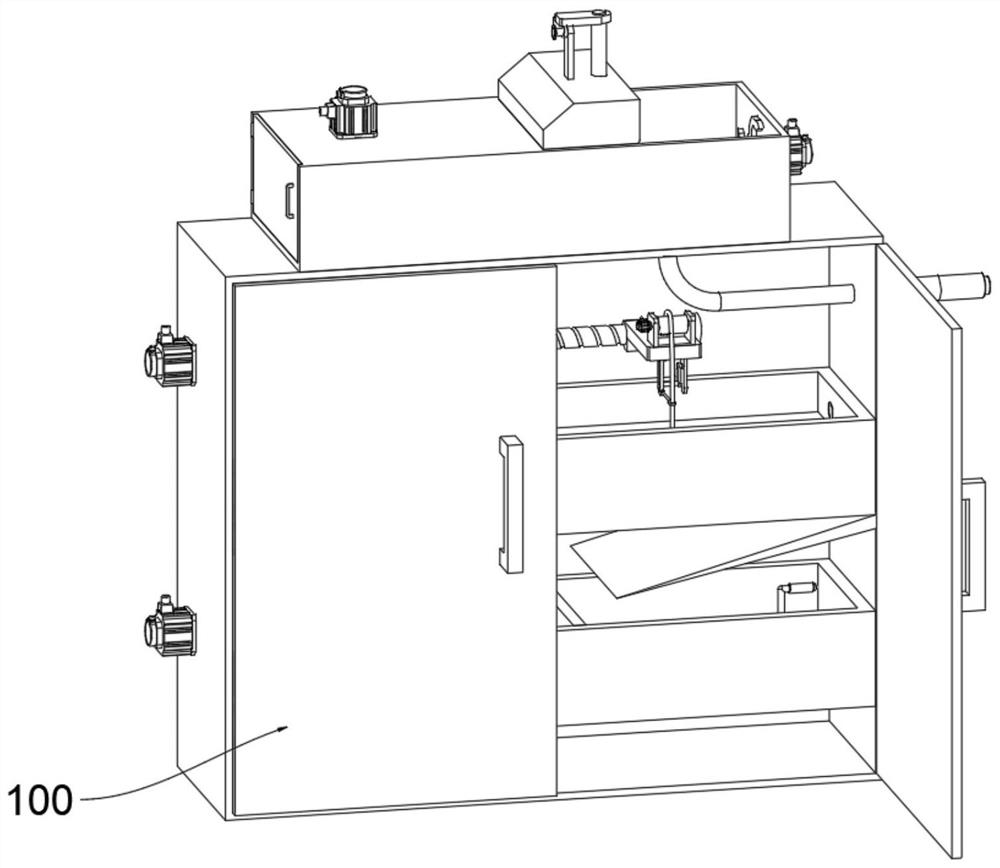

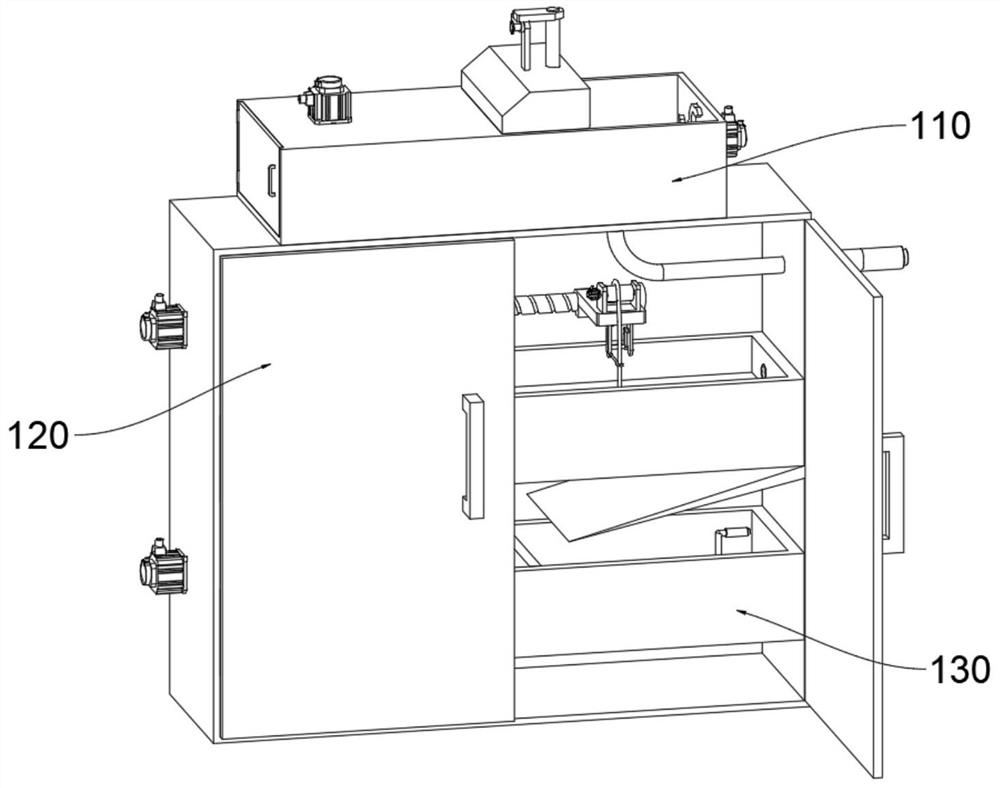

[0043] see Figure 1-Figure 8As shown, the purpose of this embodiment is to provide a multi-sorting waste recycling equipment in building construction, including a sorting device 100, and the sorting device 100 at least includes:

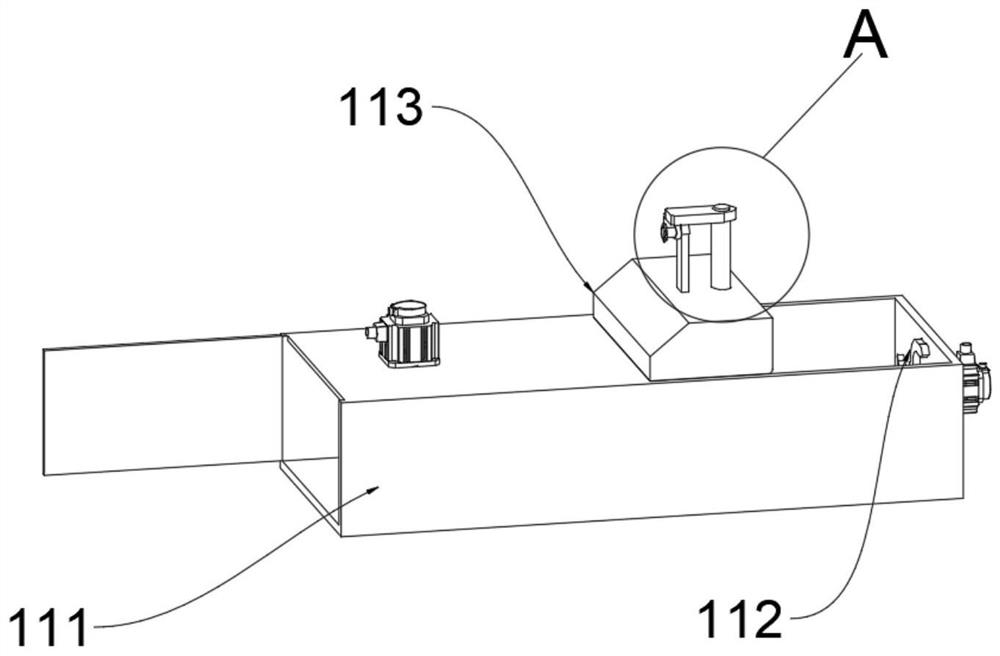

[0044] The light material sorting body 110, the light material sorting body 110 includes the light material sorting box 111 provided, the inside of the light material sorting box 111 is connected with the leaf fan 112 through the rotation of the outer motor provided on the outer wall, close to the light material sorting box The middle part of 111 is provided with feeding chamber 113, and the interior of feeding chamber 113 is installed with a plurality of turning boards 1141 through the turning rod 114, and the turning boards 1141 are connected through the rod body;

[0045] When the light material sorting body 110 of the present invention is actually used, first the external motor is connected to the power supply to drive the leaf fan 112 to rotate...

Embodiment 2

[0052] In order to reduce the accumulation of light materials inside the feeding chamber 113, the difference between this embodiment and Embodiment 1 is that please refer to Figure 9 Shown:

[0053] Among them, one end of the surface of the light material sorting box 111 is connected with a rotating shaft 116 through the top motor provided, and the surface of the rotating shaft 116 is provided with a belt rod 117 through the sleeved end plate, and the bottom of the belt rod 117 is provided with a belt plate for discharging. 118, so that after the light material is discharged through the feeding chamber 113, the top motor drives the rotating shaft 116 to operate the belt rod 117 to displace the belt plate 118 to discharge the discharged light material so that it can be discharged to the outside and reduce the light material stored in the feeding as much as possible. The inside of cavity 113.

[0054] Secondly, one end of the light material sorting box 111 is hinged with a cov...

Embodiment 3

[0056] In order to make the practical effect of the immersion box 125 better, the difference between this embodiment and Embodiment 2 is that please refer to Figure 10 Shown:

[0057] Wherein, the immersion box 125 is a hollow structure, and the interior of the immersion box 125 is provided with a hinged inner panel 1251, and the end of the inner panel 1251 is provided with a turntable, so that the inner panel 1251 is turned downward by the action of the turntable, and the magnetic attraction inside After the process, the waste metal is discharged downward again; secondly, the inside of the immersion box 125 can be passed into water flow, and then a certain amount of acid solution or rust remover can be put in, so that the rusty metal produced on the surface can be derusted , so that the sorted metal can be convenient for secondary utilization and recovery, and the water flow can be opened and discharged through the water pipe provided at one end of the immersion box 125 afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com