Scissors-fork type electric control material conveying box with overturning function

A scissor-type, electronically controlled technology, applied in the direction of lifting devices, lifting frames, etc., can solve problems such as difficult to meet market demand, low level of mechanical automation, and affecting production capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention will be described below with reference to the accompanying drawings, and the exemplary examples are intended to be construed as they are intended to limit the scope of the invention.

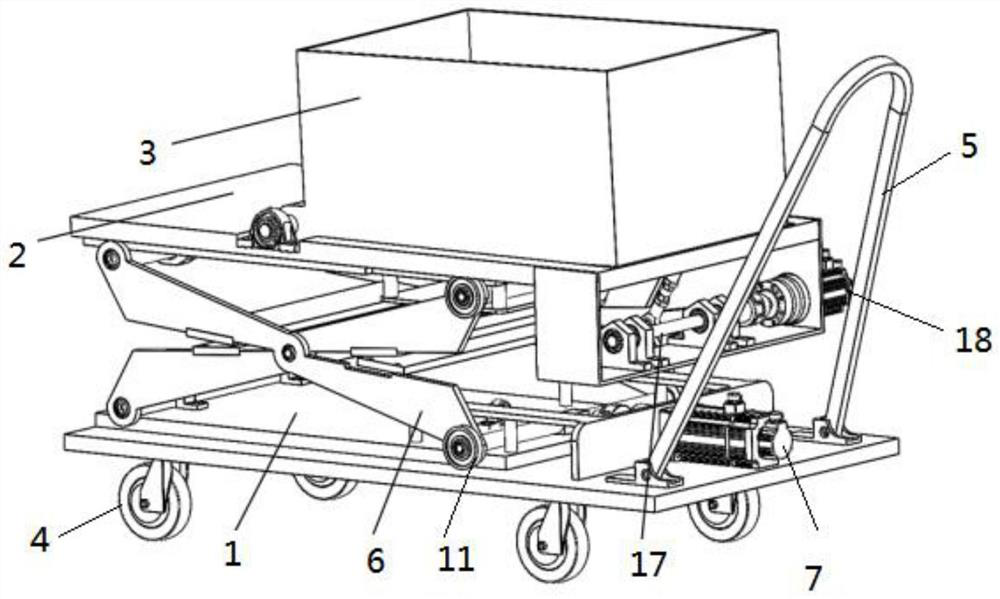

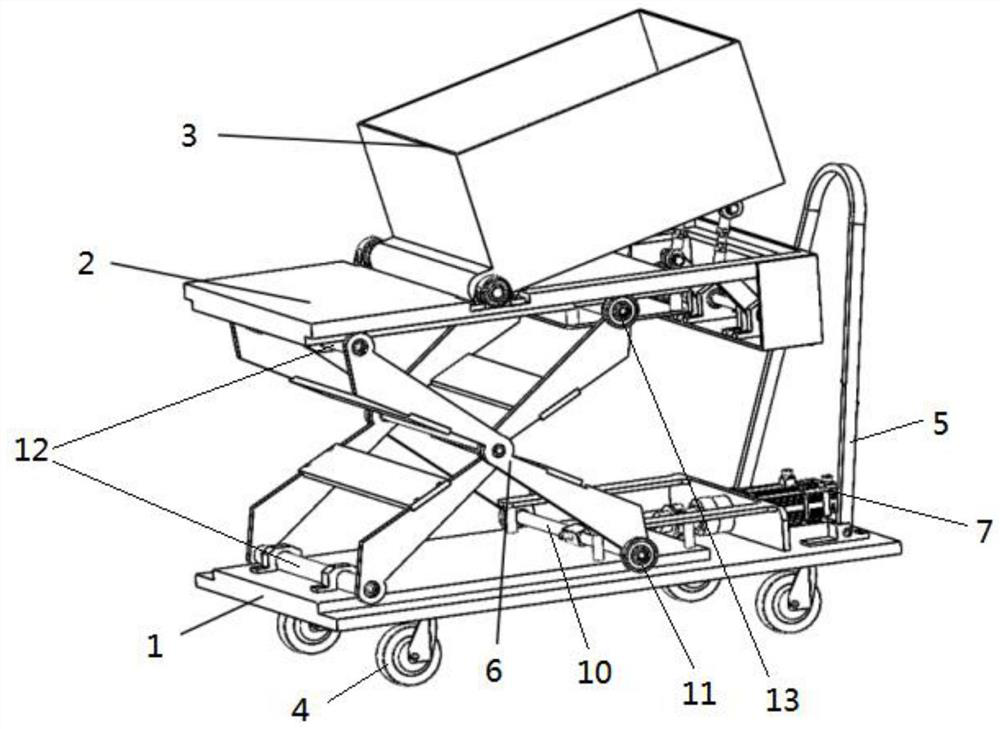

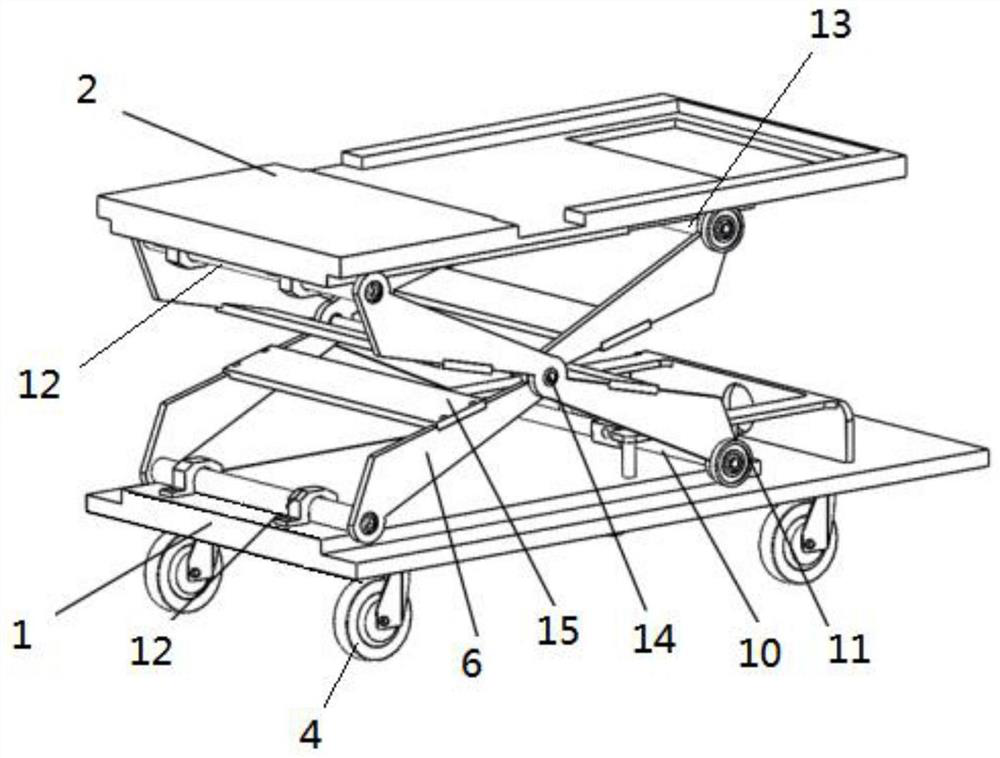

[0032] like figure 1 with 2 As shown, a scratched conduit is flipped, including carrier base 1, a lifting mechanism, a table 2, a flip device, and a material box 3. The carrier base 1 is mounted with a 10,000-way wheel 4, and the rear portion is mounted manually, the handle 5 drawn by the carrying base 1 is mounted. The lifting mechanism is mounted above the carrier base 1 and stretchable or contracted, the working table 2 mounted on the lifting mechanism and raises or decreases as the lift mechanism extends or contracted synchronously or decreases. The flip device is mounted below the rear end of the workbench 2, which can move up and down. The material box 3 is in the work table 2, and the front end bottom of the material box 3 is hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com