Winding type spiral line spoiler for restraining wind direction vibration of steel pipe tower web member

A helical and winding technology, applied to towers, protective buildings/shelters, building types, etc., can solve complex, unreliable fixation, high vibration frequency, etc., to reduce the correlation of vibration, reduce The effect of spatial correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

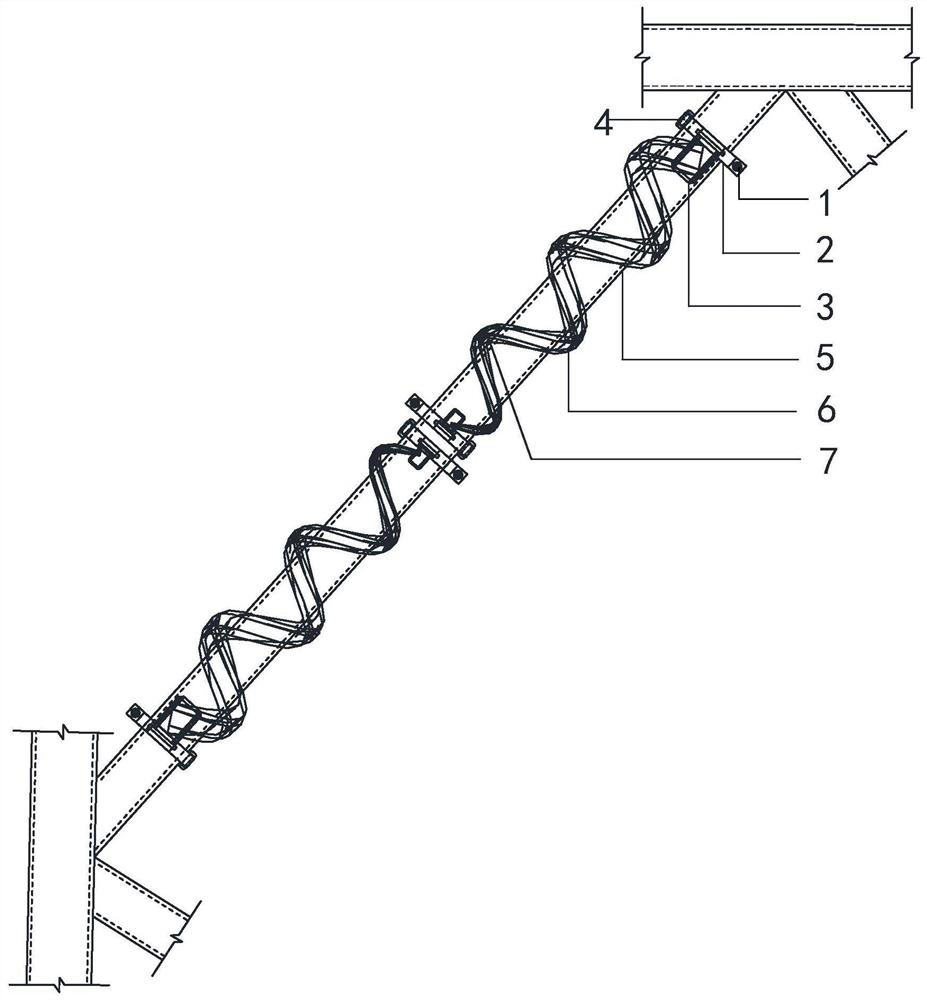

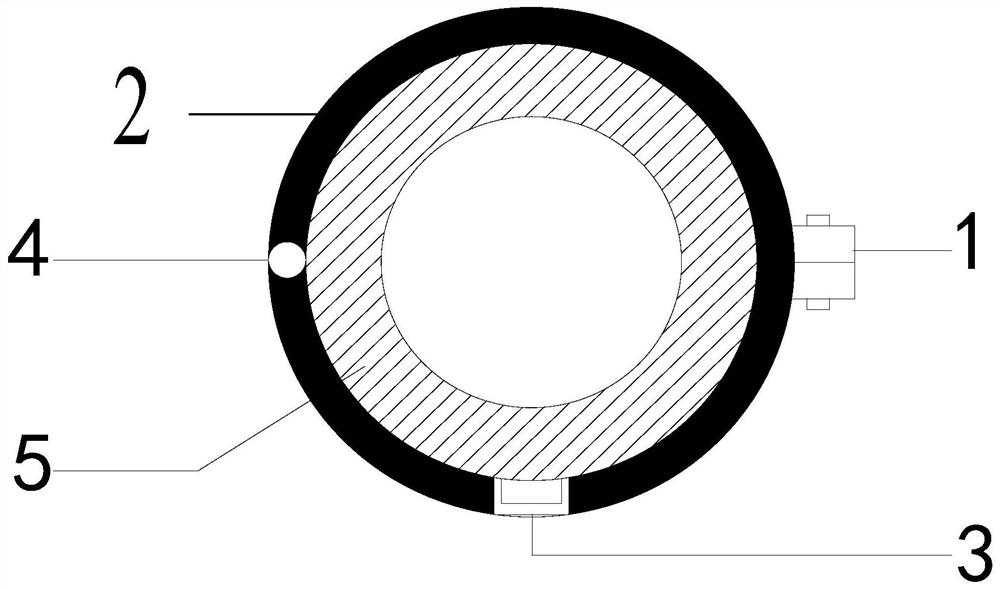

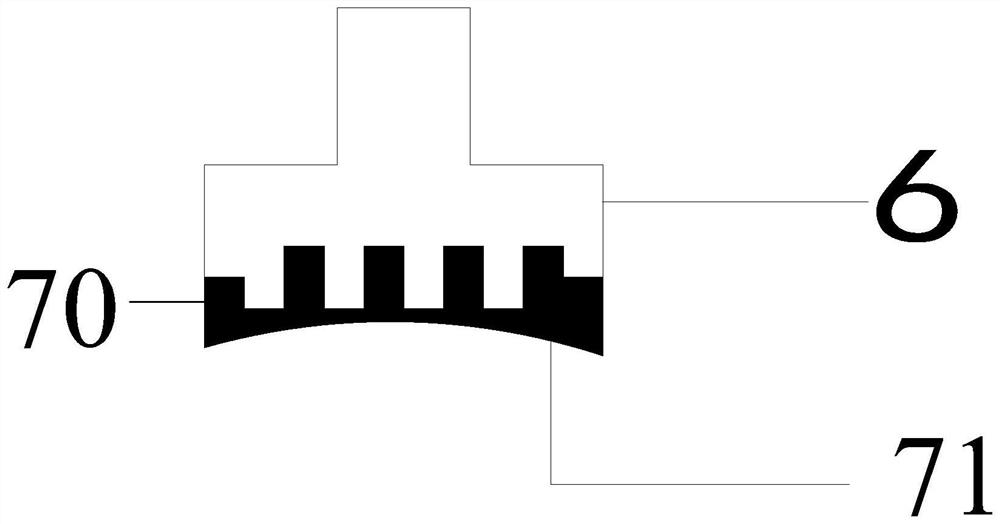

[0043] figure 1 It is a structural schematic diagram of a winding helical spoiler for suppressing wind direction vibration of a steel pipe tower web according to an embodiment of the present invention; figure 2 It is a helical cross-sectional view of a winding helical spoiler for suppressing the wind direction vibration of steel pipe tower web pole according to the embodiment of the present invention; image 3 It is a structural diagram of a positioning member for a wound helical spoiler used to suppress wind direction vibration of a steel pipe tower web according to an embodiment of the present invention. As shown in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com