Agricultural ventilator wind collector and design method thereof

A design method and technology for air collectors, which are applied in agricultural machinery, mechanical equipment, machines/engines, etc., can solve problems such as use by ordinary technicians, improve ventilation energy efficiency ratio, improve internal flow pattern, and increase gain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

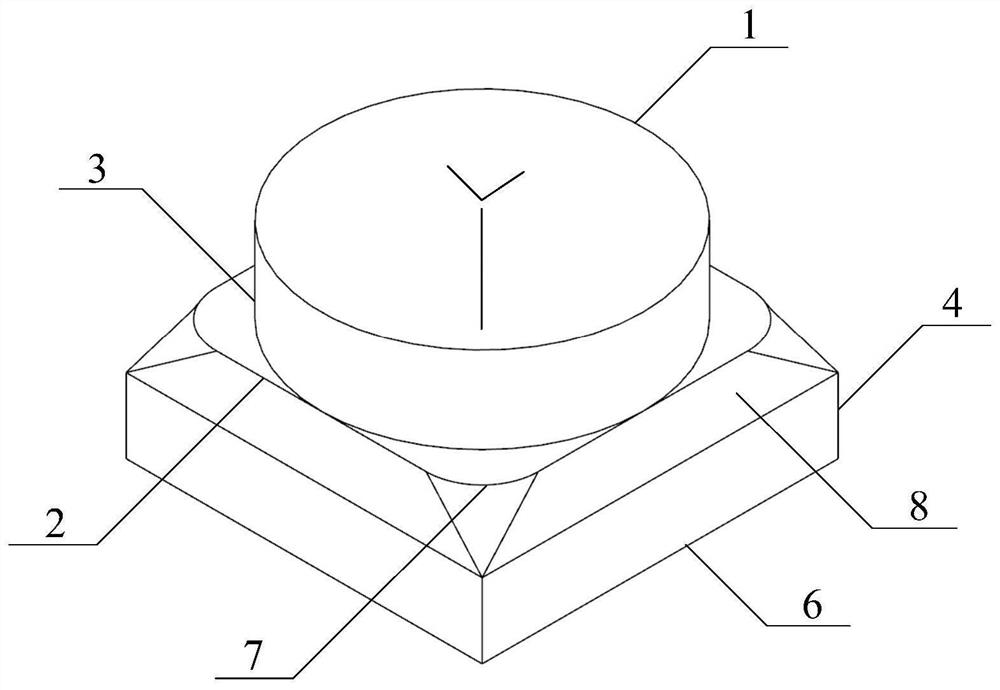

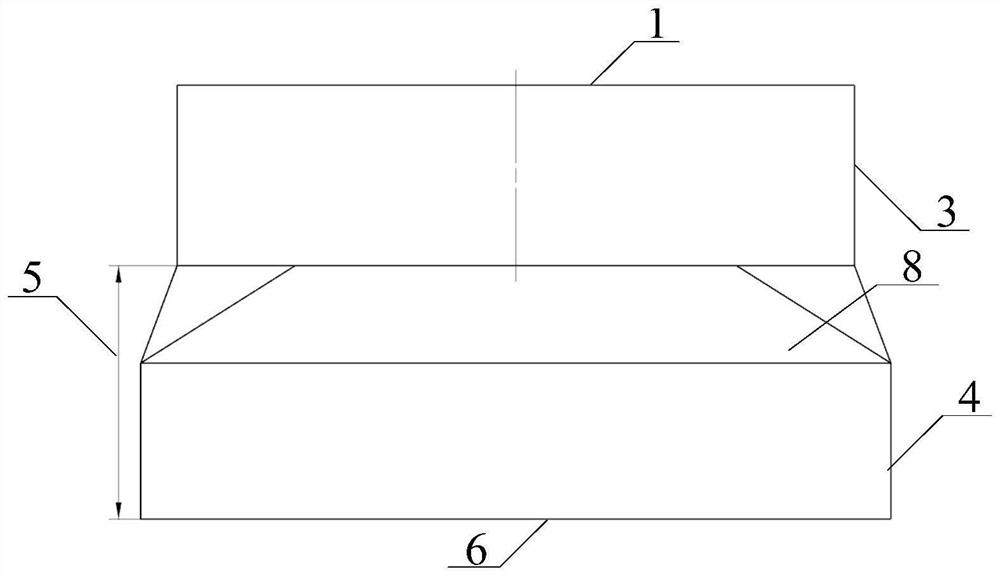

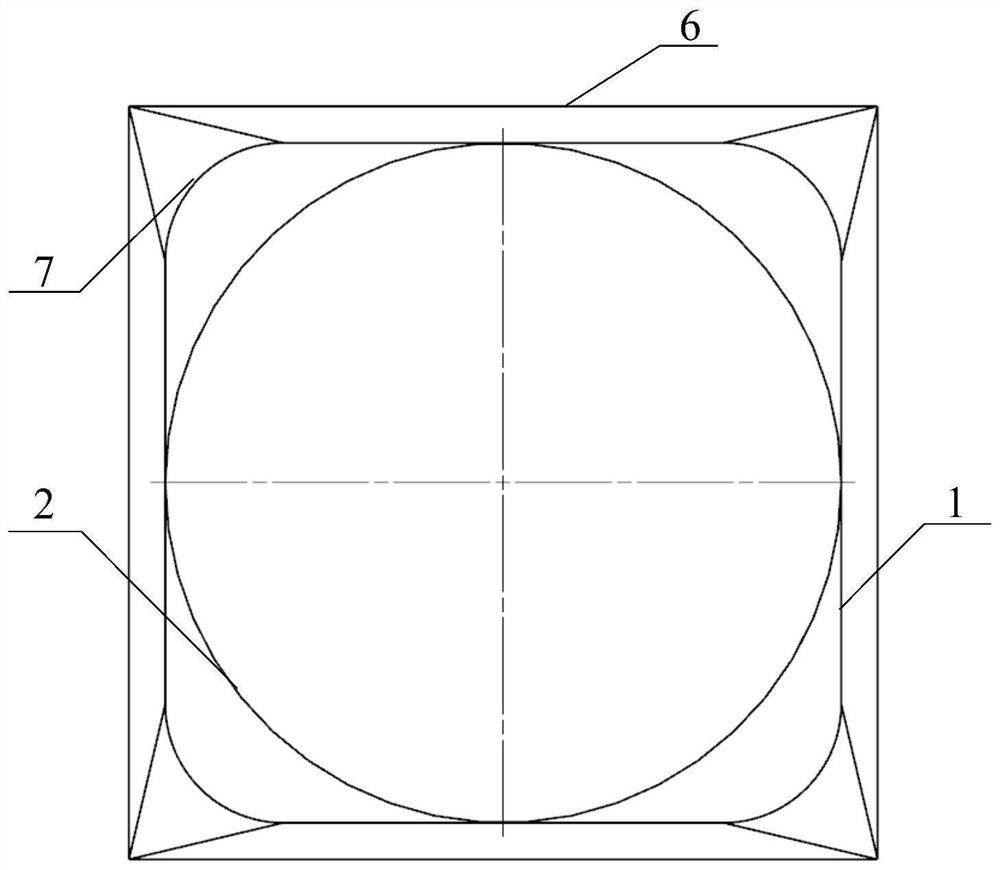

[0090] A 24-inch agricultural fan air collector structure such as Figure 1a , Figure 1b with Figure 1c Shown (the 24-inch agricultural ventilator is hereinafter referred to as the prototype). The speed of the fan is 825r / min, the diameter of the air collector outlet 1 is 683mm, the length of the inlet straight section 4 is 130mm, the length of the inlet side 6 is 762mm, and the radius of the air collector fillet 7 is 100mm.

[0091] Under design conditions, the prototype has a ventilation volume of 9352.698m3 / h and a ventilation energy efficiency ratio of 18.76m 3 / (h·W).

[0092] In order to improve the above-mentioned 24-inch agricultural fan collector, the following steps are taken:

[0093] S1. Measure the diameter of the air collector outlet 1 of the 24-inch agricultural fan air collector X3

[0094] After measurement, the diameter X3 of the air collector outlet 1 is 683 mm.

[0095] S2. Determine the weight of ventilation volume and ventilation energy efficiency ...

Embodiment 2

[0120] A 24-inch agricultural axial flow fan adopts the following steps:

[0121] S1. Measure the diameter of the air collector outlet 1 of the 24-inch agricultural fan air collector X3

[0122] After measurement, the diameter X3 of the air collector outlet 1 is 685mm.

[0123] S2. Determine the weight of ventilation volume and ventilation energy efficiency ratio

[0124] Set the weight of ventilation volume and ventilation energy efficiency ratio to 5:6.

[0125] S3. Determine the target ventilation volume or target ventilation energy efficiency ratio

[0126] Determine the ventilation volume of the air collector of the agricultural ventilator as 9353.116×125%=11691.395m 3 / h, ventilation energy efficiency ratio is 19.01×125%=23.76m 3 / (h·W).

[0127] S4. Solve the structural parameters of the air collector

[0128] For the air collector of a 24-inch agricultural fan, the function model of the ventilation volume, ventilation energy efficiency ratio and the structural pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com