Rotating wheel type cannon

A wheel-type, cannon technology, applied in the direction of the launch device, can solve the problems of reducing the mobility of the cannon, being easily detected by the enemy, and the low survival rate of the cannon, so as to improve the safety, mobility and concealment of soldiers. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

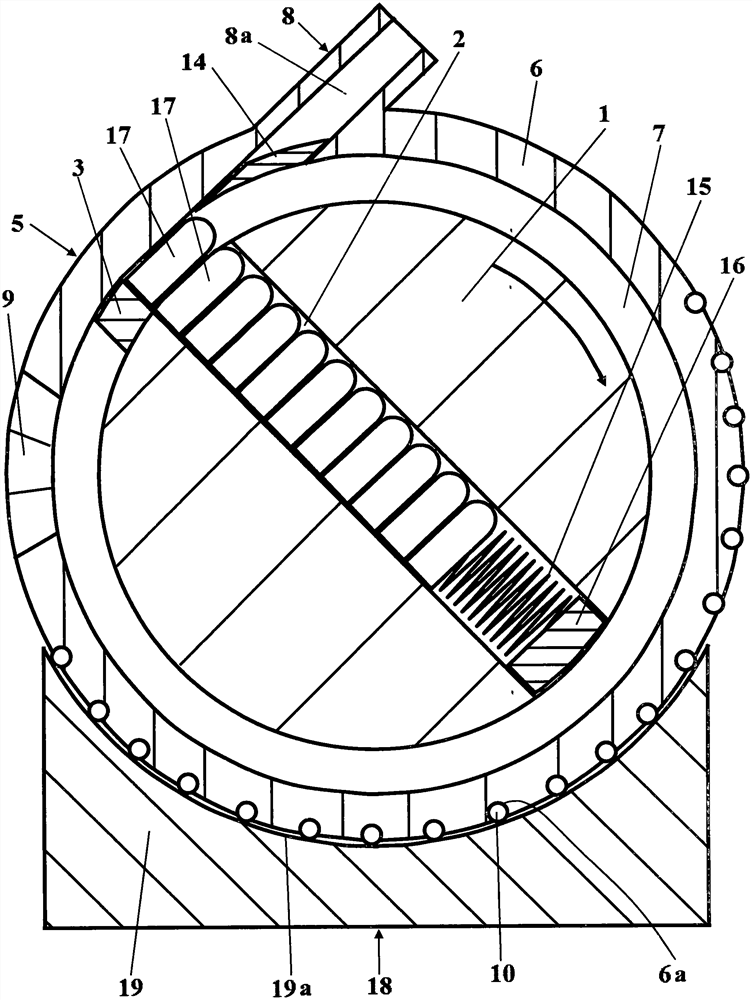

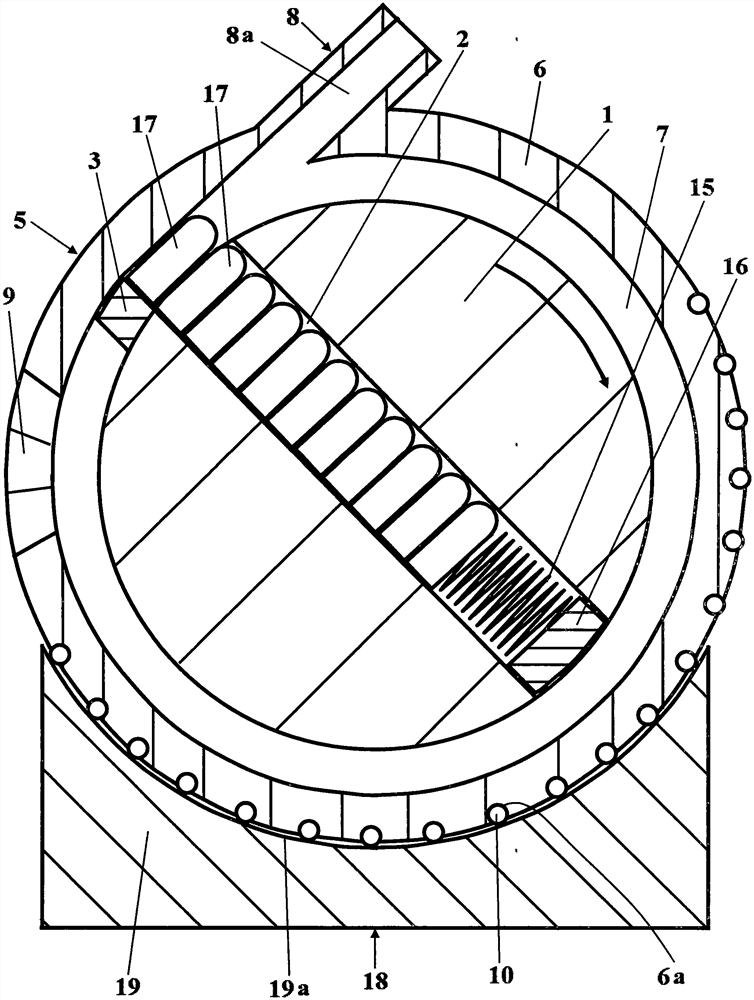

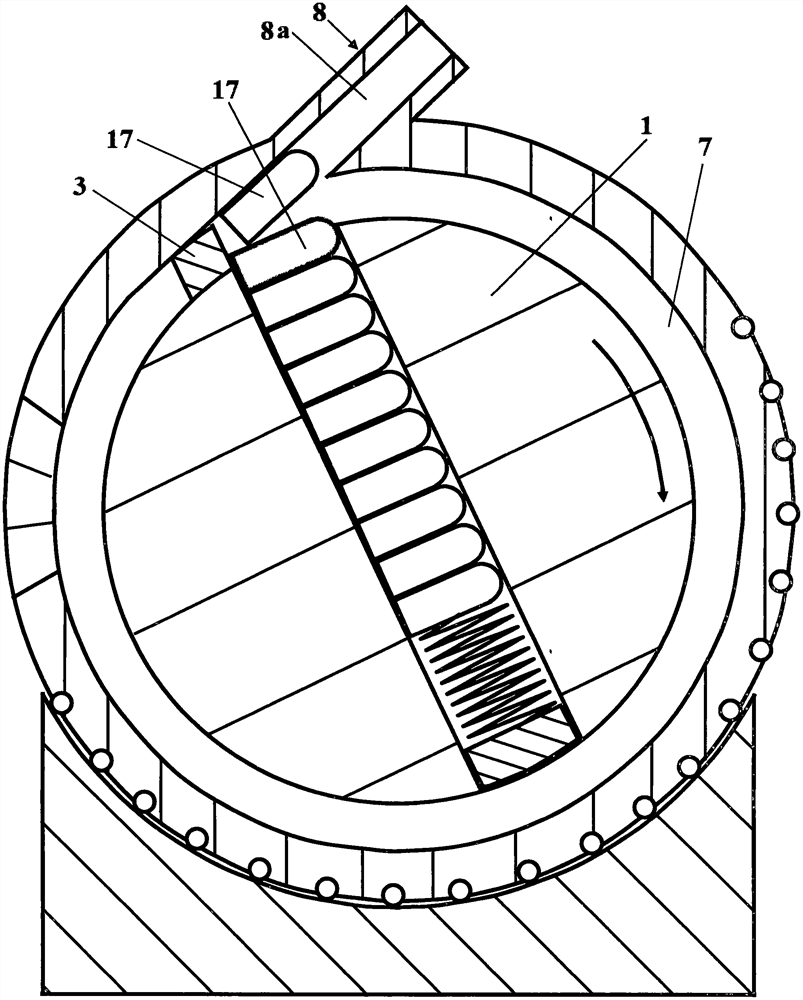

[0070] like Figure 1 to Figure 5 Shown in each figure, a kind of runner type cannon comprises runner 1, shell 5, gun mount 18, projectile 17, rotating shaft, ball pressing device and drive unit.

[0071] like Figure 1 to Figure 4 As shown in each figure, the projectile 17 does not contain a barrel and the propellant powder contained in the barrel, and it is composed of a cylindrical body and a streamlined warhead. The inner chamber of the body is filled with explosive powder. Install the fuze in.

[0072] like figure 1 , Figure 5 Shown, this runner 1, its axis is horizontal, and magazine chamber 2 is arranged inside it, and bullet holder 3 is fixedly connected on its peripheral surface.

[0073] like figure 1 , Figure 5 As shown, the magazine 2, which is a cuboid-shaped cavity for installing shells 17, runs through the runner 1 in the radial direction, and its open two ends are respectively the inlet end and the ejection end, and its center is located at the runner 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com