Electronic product full-automatic aging system and method

An electronic product, fully automatic technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problem of low aging efficiency of electronic products, and achieve the effect of easy management, reduced manpower requirements, and easy efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

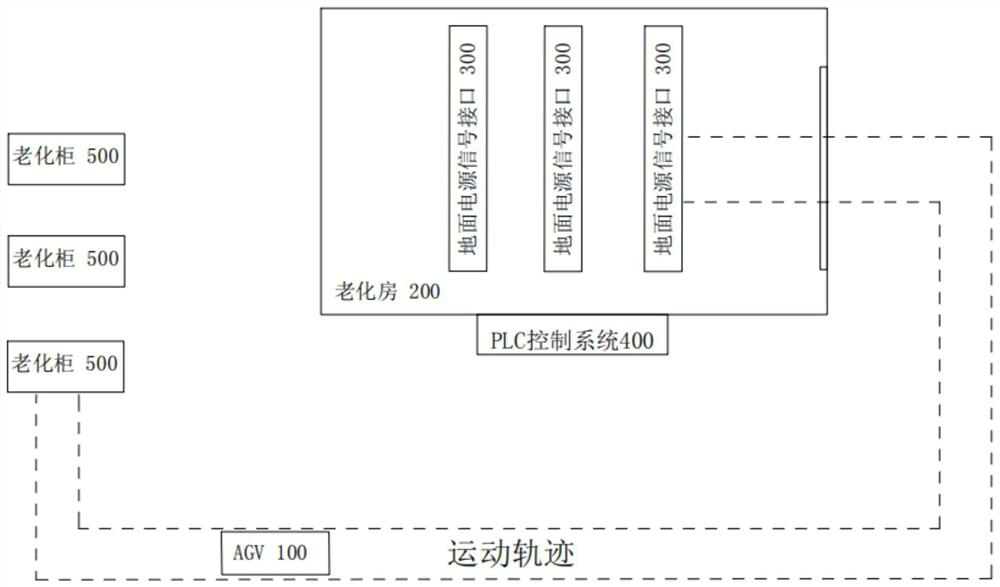

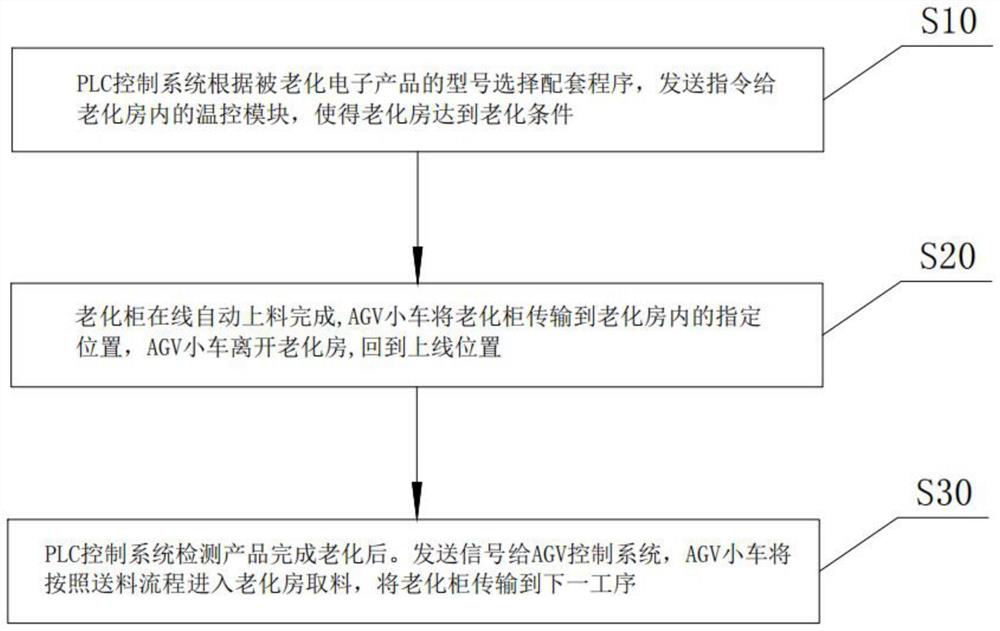

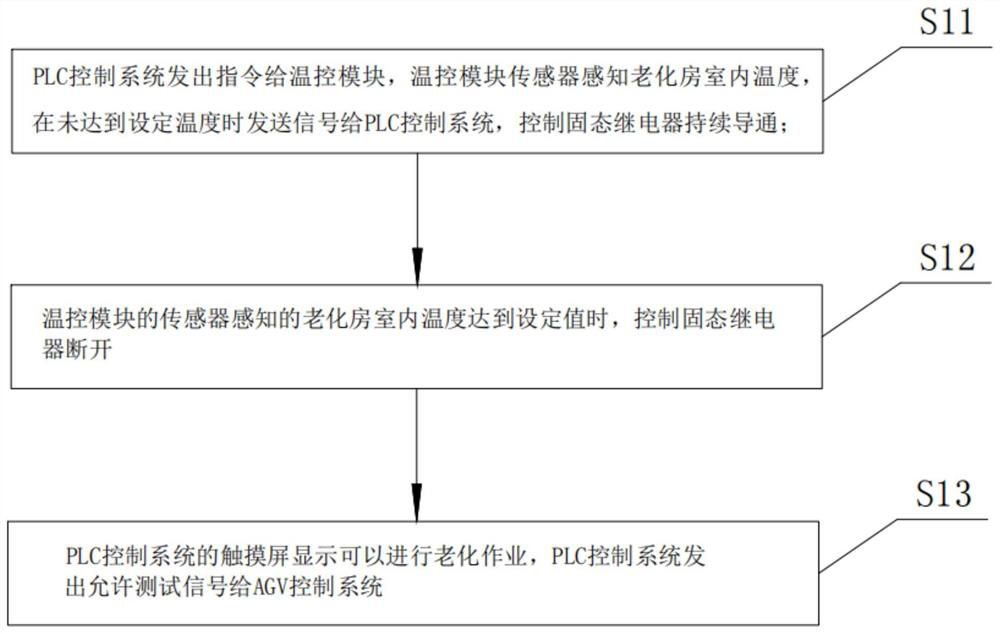

[0040] Such as figure 1 As shown, this embodiment provides a technical solution: a fully automatic aging system for electronic products, including AGV100, aging room 200, ground power signal interface 300, PLC control system 400 and multiple identical aging cabinets 500; wherein,

[0041] The aging cabinet 500 includes multiple sets of aging fixtures for clamping and fixing products to be aged and signal input interfaces matching the products to be aged;

[0042] The AGV100 and the PLC400 control system transmit signal instructions wirelessly;

[0043] The ground power signal interface 300 is arranged in the agin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com