Round bar center hole machining device

A processing device and center hole technology, applied in positioning devices, metal processing, metal processing equipment, etc., can solve the problems of round bar adjustment, affecting the accuracy and efficiency of processing holes, and high rework rate, so as to prevent shaking and dislocation and improve Practicality and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

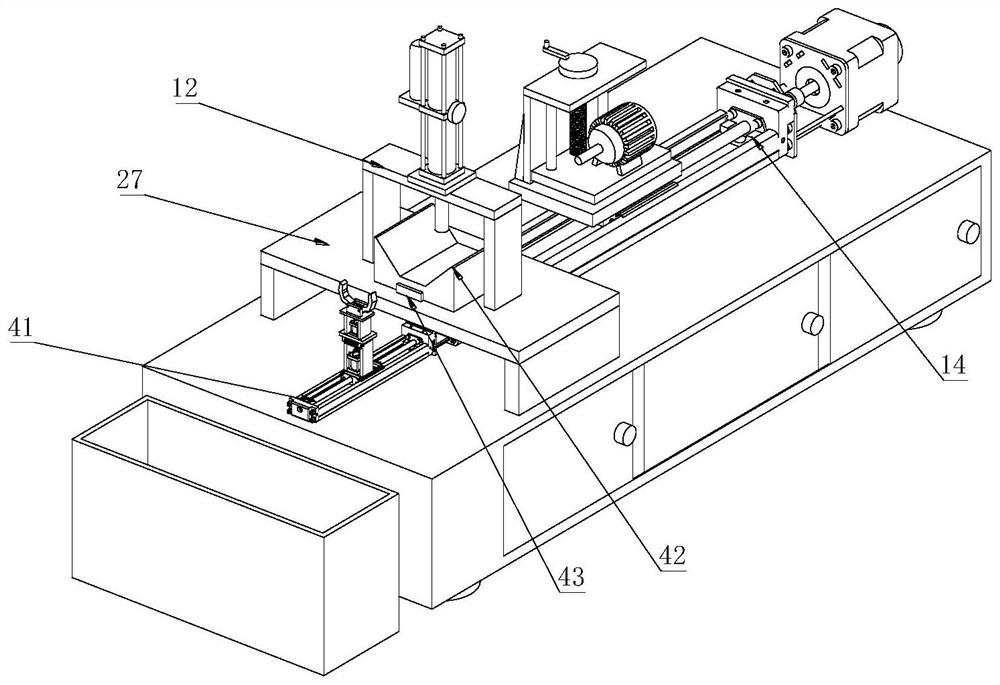

[0045] Such as figure 1 As shown, a round bar center hole processing device includes:

[0046] Workbench 1;

[0047] Compression limit assembly 3, the compression limit is set on one side of the top of workbench 1;

[0048] An adjustable drilling assembly 2, the adjustable drilling assembly 2 is arranged on the side of the top of the workbench 1 away from the compression limit assembly 3;

[0049] Clamping assembly 4, the clamping assembly 4 is arranged below the compression limit assembly 3;

[0050] Automatic blanking assembly 5, the automatic blanking assembly 5 is arranged on the side of the top of the workbench 1 close to the clamping assembly 4;

[0051] Wherein, the compression limit assembly 3 includes a mounting table 27, a fixed frame 12 and a gas-liquid conversion cylinder 11, the mounting table 27 is arranged on one side of the top of the workbench 1, and the fixed frame 12 is arranged on the side of the mounting table 27. At the top, the gas-liquid conversion ...

Embodiment 2

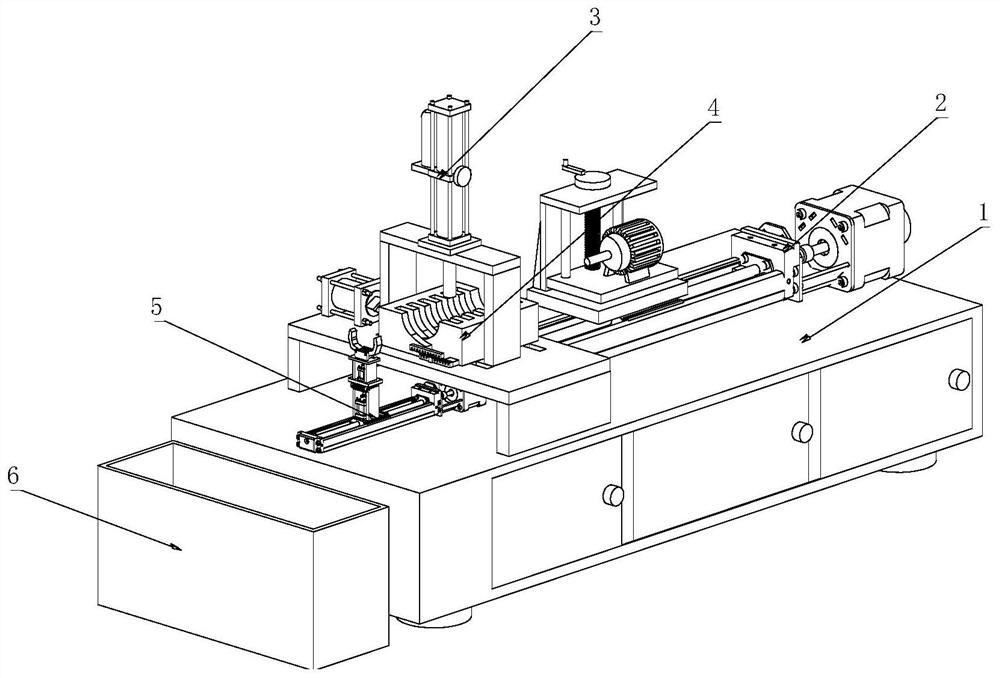

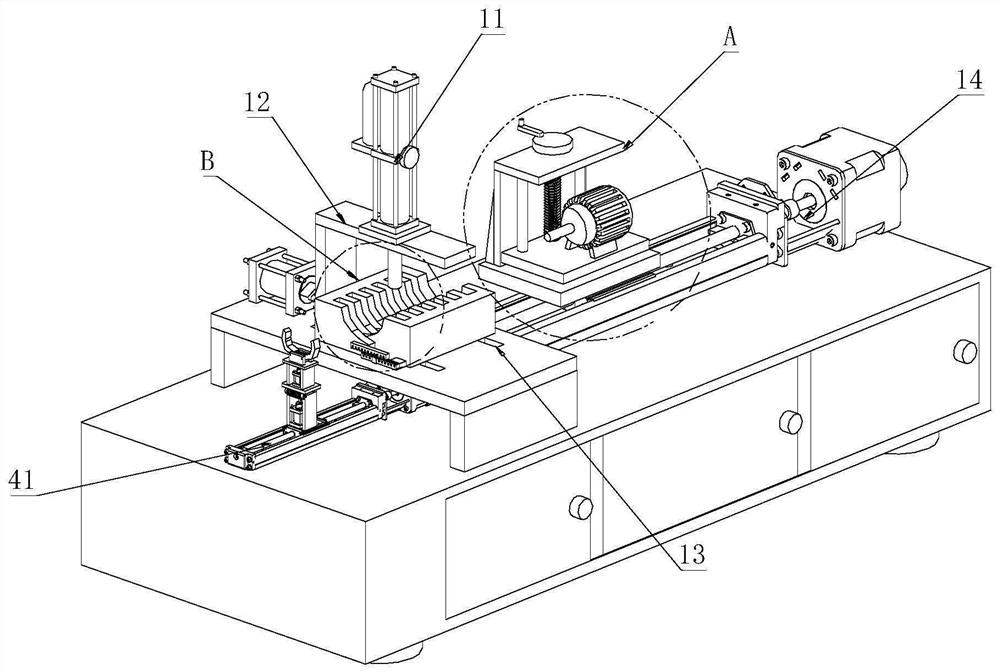

[0054] Such as Figure 2-9 As shown, a round bar center hole processing device includes:

[0055] Workbench 1;

[0056] Compression limit assembly 3, the compression limit is set on one side of the top of workbench 1;

[0057] An adjustable drilling assembly 2, the adjustable drilling assembly 2 is arranged on the side of the top of the workbench 1 away from the compression limit assembly 3;

[0058] Automatic blanking assembly 5, the automatic blanking assembly 5 is arranged on the side of the top of the workbench 1 close to the clamping assembly 4;

[0059] Wherein, the compression limit assembly 3 includes a mounting table 27, a fixed frame 12 and a gas-liquid conversion cylinder 11, the mounting table 27 is arranged on one side of the top of the workbench 1, and the fixed frame 12 is arranged on the side of the mounting table 27. At the top, the gas-liquid conversion cylinder 11 is vertically arranged on the top of the fixed frame 12, and the output shaft of the gas-liq...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap