Large-bulk high-quality scintillation crystal and preparation method and application thereof

A scintillation crystal, high-quality technology, applied in the direction of crystal growth, chemical instruments and methods, measuring devices, etc., to achieve the effect of good crystal quality, small refractive index, and short decay time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

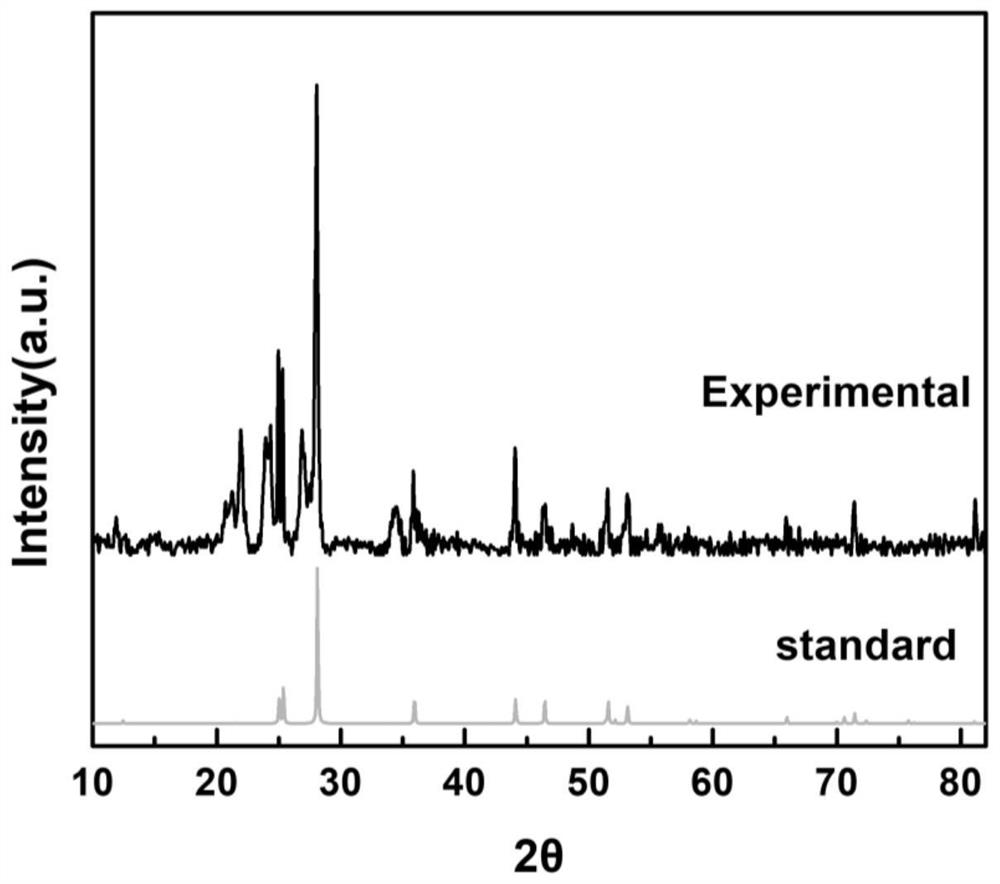

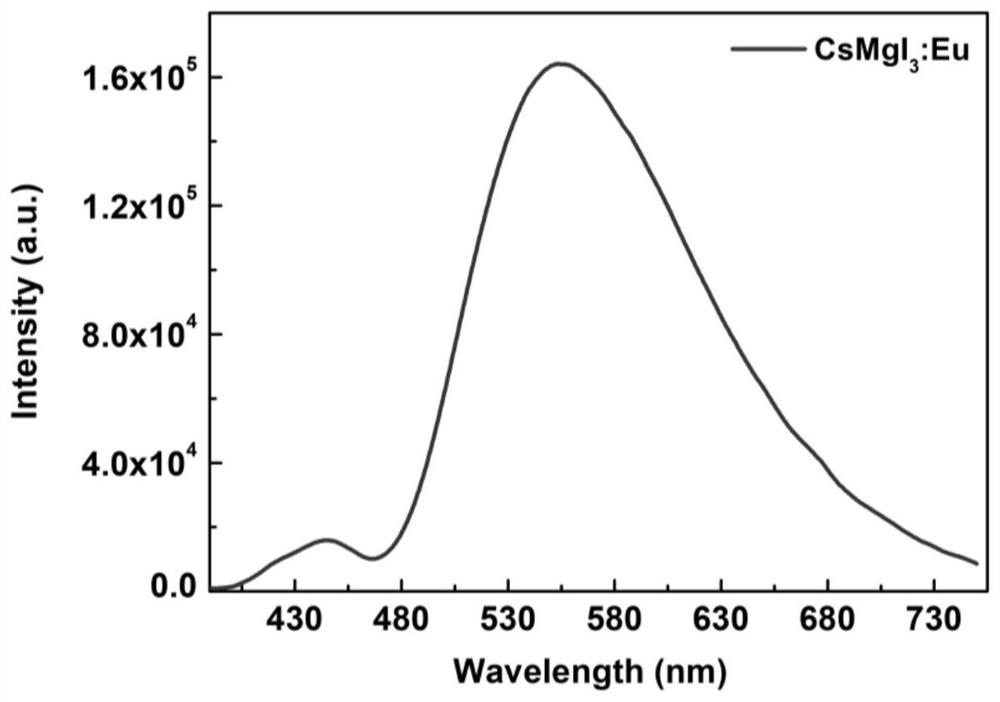

[0063] CsMg 0.99 Eu 0.01 I 3 The preparation of bulk crystals, the steps are as follows:

[0064] 1) CsI, MgI in the glove box 2 and EuI 2 Mix evenly according to the stoichiometric ratio, put it into a quartz tube and seal it, and the vacuum degree reaches 10 –6 mbar.

[0065] 2) Put the sealed quartz tube into a resistance furnace, heat up to 450°C at a rate of 100°C / h, then cool down to 100°C at a rate of 50°C / h, and then heat up to 450°C at a rate of 100°C / h , after three cycles, keep the temperature at 450°C for 10 hours, and then lower it to 25°C at a rate of 15°C / h to obtain CsMg 0.99 Eu 0.01 I 3 Polycrystalline;

[0066] 3) will contain CsMg 0.99 Eu 0.01 I 3 Put the polycrystalline quartz tube into the crucible drop furnace, heat up to 420°C, keep it warm for 10 hours, adjust the position of the quartz tube so that the temperature at the bottom of the quartz tube at the spontaneous nucleation area or the seeding area is 1-5°C higher than the melting point, ...

Embodiment 2

[0072] CsMg 0.95 Eu 0.05 Cl 3 The preparation of bulk crystals, the steps are as follows:

[0073] 1) In the glove box, mix CsCl, MgCl2 and EuCl2 evenly according to the stoichiometric ratio, put them into a quartz tube and seal it, and the vacuum degree reaches 10 -6 mbar.

[0074] 2) Put the sealed quartz tube into a resistance furnace, heat up to 650°C at a rate of 100°C / h, then cool down to 100°C at a rate of 50°C / h, and then heat up to 650°C at a rate of 100°C / h , after three cycles, keep the temperature at 650°C for 10 hours, and then lower it to 25°C at a rate of 15°C / h to obtain CsMg 0.95 Eu 0.05 Cl 3 Polycrystalline;

[0075] 3) will contain CsMg 0.95 Eu 0.05 Cl 3 Put the polycrystalline quartz tube into the crucible drop furnace, raise the temperature to 615°C, keep it warm for 10 hours, adjust the position of the quartz tube so that the temperature at the bottom of the quartz tube at the spontaneous nucleation area or the inoculation area is 1-5°C higher t...

Embodiment 3

[0080] CsMgCl 3 The preparation of bulk crystals, the steps are as follows:

[0081] 1) In the glove box, mix CsCl and MgCl2 evenly according to the stoichiometric ratio, put them into a quartz tube and seal them, and the vacuum degree reaches 10 –6 mbar.

[0082] 2) Put the sealed quartz tube into a resistance furnace, heat up to 650°C at a rate of 100°C / h, then cool down to 100°C at a rate of 50°C / h, and then heat up to 650°C at a rate of 100°C / h , after three cycles, keep the temperature at 650°C for 10 hours, and then lower it to 25°C at a rate of 15°C / h to obtain polycrystalline CsMgCl3;

[0083] 3) Put the polycrystalline quartz tube containing CsMgCl3 into the crucible descending furnace, heat up to 615°C, keep it warm for 10 hours, adjust the position of the quartz tube so that the temperature at the bottom of the quartz tube at the spontaneous nucleation area or the inoculation area is higher than the melting point by 1- 5°C, the temperature gradient in the single cr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap