Waste-toner-free cartridge

A powder box and box body technology, which is applied in the field of electronic imaging equipment consumables, can solve the problems of waste powder agglomeration, limited volume, affecting charging and power consumption effects, etc., and achieve the effect of avoiding damage and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

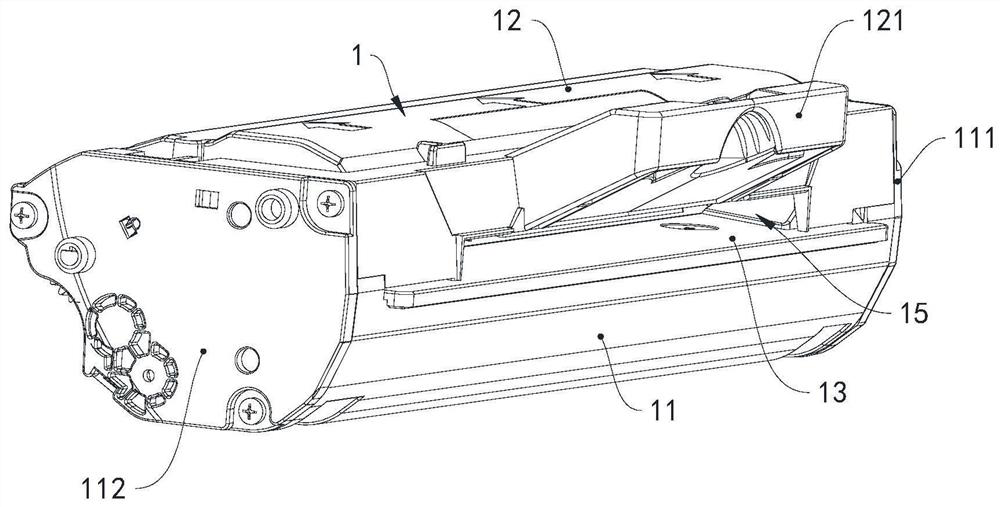

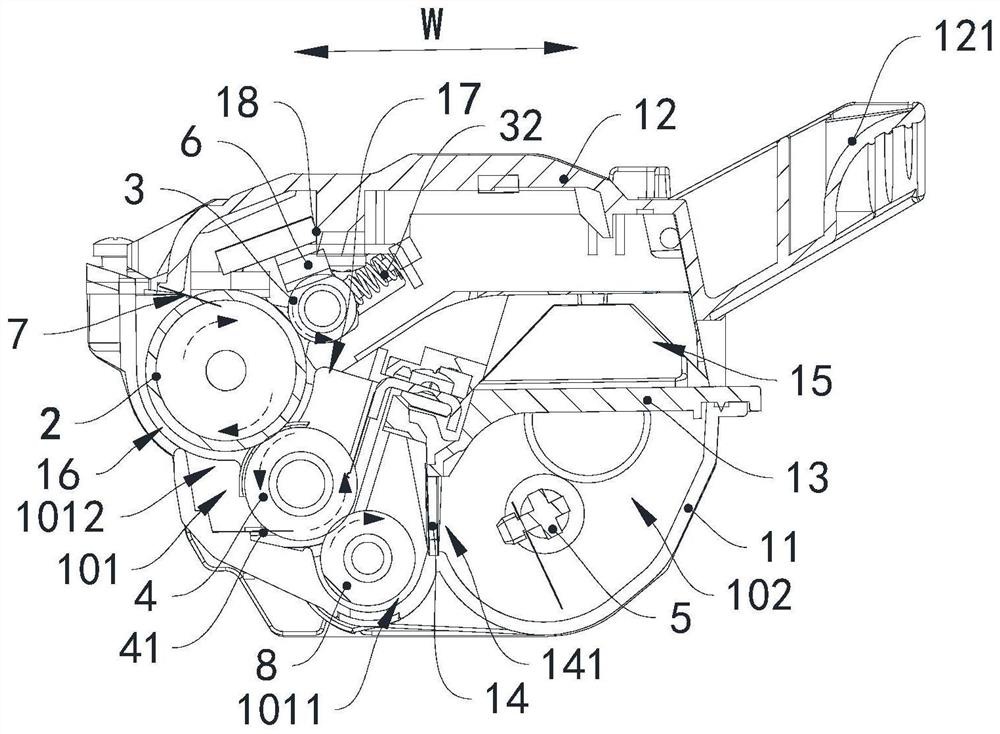

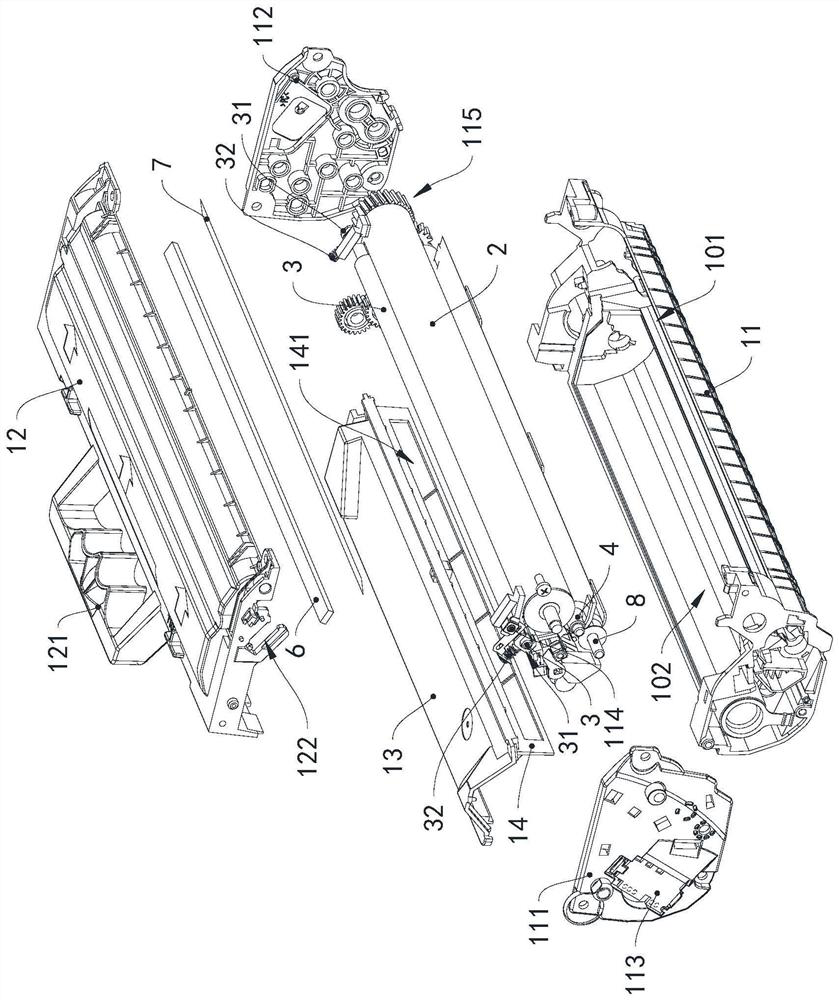

[0043] see Figure 1 to Figure 3 , The non-waste toner powder box of this embodiment includes a box body 1, a photosensitive drum 2, a charging roller 3, a developing roller 4, a powder feeding roller 8, a stirring frame 5, a cleaning member 6 and a powder knife 9. The cleaning member 6 is a cleaning brush.

[0044] The box body 1 includes a powder bin frame 11 , a first cover part 12 , a second cover part 13 , a conductive end cover 111 and a driving end end cover 112 , and the first cover part 12 and the powder bin frame 11 enclose an accommodating cavity 101 , the second cover part 13 and the powder bin frame 11 enclose the toner containing chamber 102, the powder bin frame 11 is provided with a partition wall 14, the partition wall 14 and the second cover part 13 are integrally formed, and the partition wall 14 is provided with The communication opening 141 , the accommodating chamber 101 and the toner accommodating chamber 102 are separated by the partition wall 14 and c...

no. 2 example

[0054] As an explanation of the second embodiment of the non-waste toner box of the present invention, only the differences from the above-mentioned first embodiment of the non-waste toner box will be described below.

[0055] see Figure 4 to Figure 7 , the box body 21 further includes a frame body 214 and a third cover part 215 of the powder replenishment bin. The toner supply bin frame body 214 is connected above the second cover part 213, the toner replenishment bin frame body 214 and the third cover part 215 enclose the toner replenishment bin 203, the toner replenishment bin 203 is located above the toner accommodating chamber 202 and The laser channel 216 communicates with the toner storage cavity 202 and is located between the second cover part 213 and the frame body 214 of the toner supply bin. The first cover member 212 and the third cover member 215 are arranged along the width direction W of the case body 21 .

[0056] Two powder filling ports 2131 are opened on ...

no. 3 example

[0060] As the description of the third embodiment of the waste toner box without waste toner of the present invention, only the differences from the first embodiment of the waste toner box without waste toner will be described below.

[0061] In this embodiment, the cleaning brush is made of fibers with conductive carbon black. The cleaning member is electrically connected to the charging roller electrode.

[0062] The cleaning member can conduct electricity, which can change the electrical properties of the toner. For example, under normal circumstances, when the photosensitive drum is exposed and developed, the toner on the surface of the photosensitive drum is charged negatively, but the electrical property may change during the working process. If it is not treated, the toner in the developing chamber will form agglomerates due to the attractive force between the positive and negative charges after the waste toner enters the developing chamber, which will affect the printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com