Steel bar structure manufacturing system and method

A manufacturing method and manufacturing system technology, applied in the field of steel bar material processing, can solve the problems of low material utilization rate, more waste of power and gas consumption, and more residual waste, so as to improve enterprise production efficiency, reduce manual labor intensity, and simplify the system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

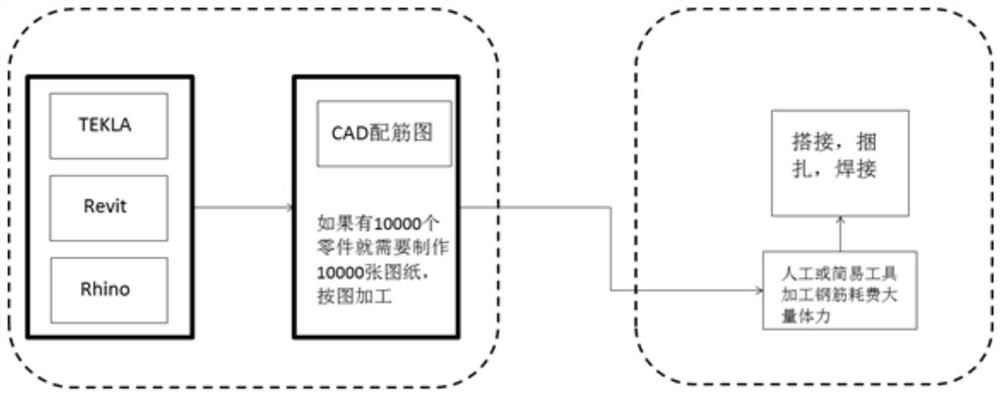

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific diagrams.

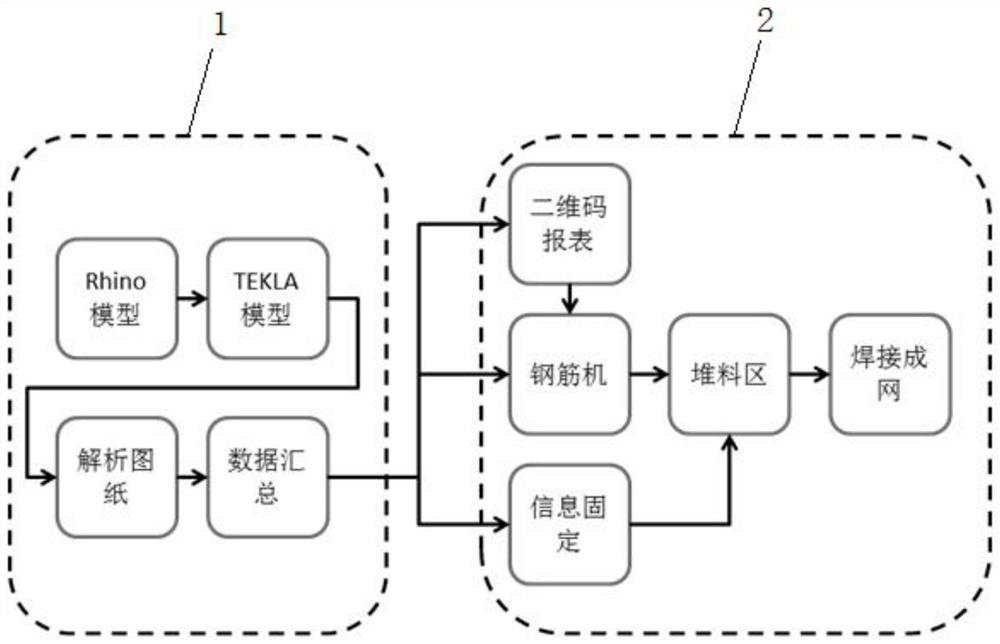

[0034] The first embodiment of the present invention discloses a steel structure manufacturing system, such as figure 2 As shown, it includes BIM design terminal 1 and CAM production terminal 2. The BIM design terminal 1 includes Rhino model software, TEKLA model software, analytical drawing software and data summary software connected in sequence. CAM production terminal 2 includes steel bar machine equipment, two The two-dimensional code report module, the information fixing module, the stacking area and the welding netting equipment, the data summary software are respectively connected to the two-dimensional code report module, the reinforcement machine equipment and the information fixing module, and the reinforcement machine equipment is respectively conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap