Lightning protection device of water level sensor

A water level sensor and lightning protection technology, applied in the installation of cables, buoy liquid level indicators, installation of lighting conductors, etc. Lightning protection and other issues to achieve the effect of preventing lightning damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

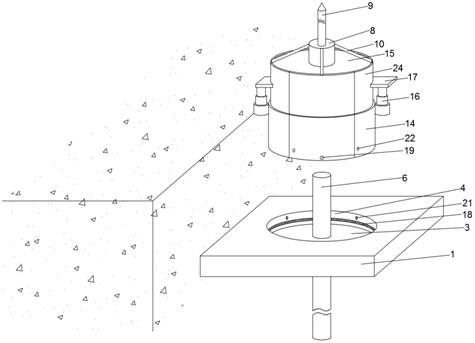

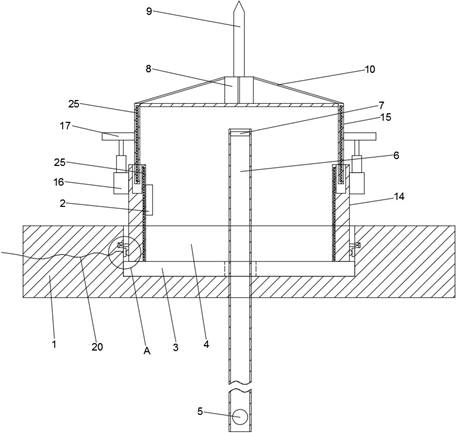

[0024] In order to better understand the technical content of the present invention, a specific embodiment is provided below, and the present invention is further described in conjunction with the accompanying drawings.

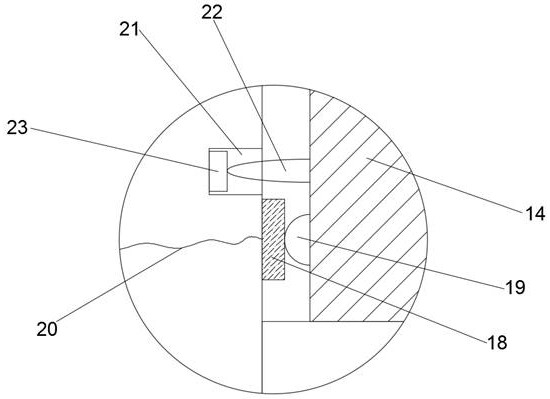

[0025] see Figure 1 to Figure 5 , a lightning protection device for a water level sensor provided by the present invention includes a float type water level sensor, a mounting plate 1, a lightning protection cover, a lightning detection mechanism, a main control unit 2 and an electric turntable 3, and the mounting plate 1 is set On the inner side wall of the reservoir, an installation groove 4 is arranged on its upper surface. The float type water level sensor includes a magnetic float 5, a measuring conduit 6 and a Hall sensor 7. The measuring conduit 6 vertically runs through the installation groove 4. The magnetic The floating ball 5 is arranged inside the part of the measuring conduit 6 below the mounting plate 1, the Hall sensor 7 is arranged on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com