Linear motor

A technology of linear motors and coils, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of limited overcurrent capacity, small motor thrust density, and large equivalent air gap of the motor, so as to improve thrust and thrust density , Strong over-current capability, and the effect of reducing thrust fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

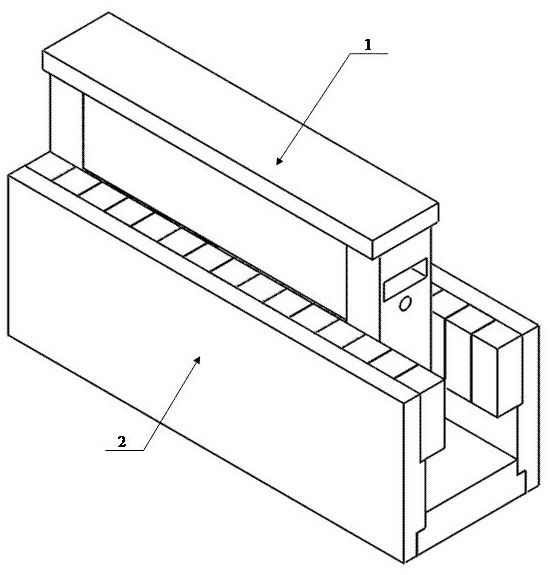

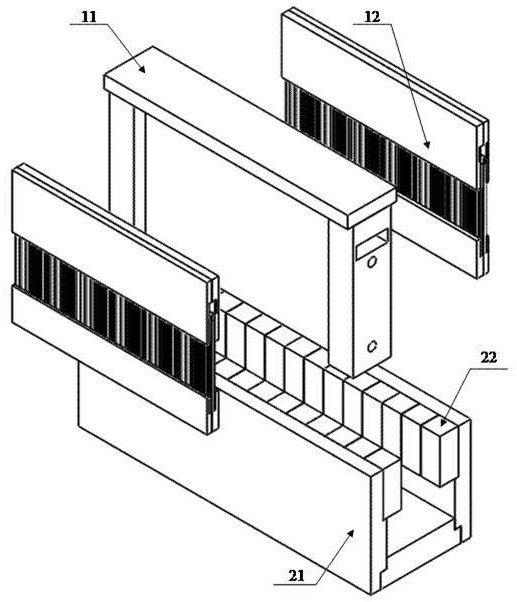

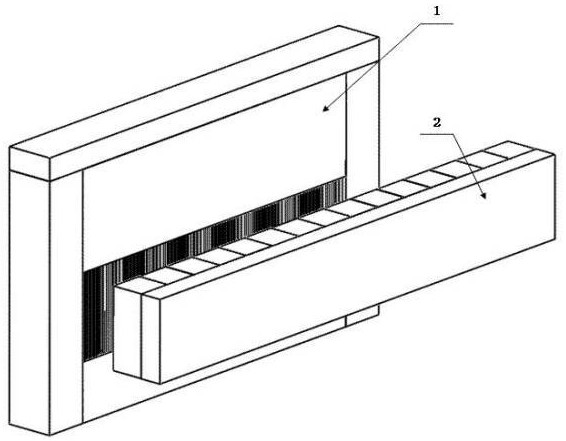

[0027] combine Figure 1 to Figure 3 As shown, a linear motor of the present invention includes a primary 1 and a secondary 2, and there is an air gap between the primary 1 and the secondary 2 . The secondary 2 includes a magnetic plate 21 and a magnetic pole 22 mounted on the magnetic plate 21 . The primary 1 is composed of a primary bottom plate 11 and a primary winding 12. The primary winding 12 is installed on one or both sides of the primary bottom plate 11 and is potted with thermally conductive and insulating curing glue to increase the rigidity and insulation of the primary 1 . Such as figure 2 As shown, when the primary winding 12 is installed on both sides of the primary bottom plate 11, a bilateral structure is formed. At this time, the secondary 2 is composed of two magnetic plates 21 respectively equipped with magnetic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap