A permanent magnet linear synchronous motor with the same polarity

A permanent magnet linear synchronous, homopolar technology, applied in magnetic circuits, electromechanical devices, electrical components, etc. characterized by magnetic materials, can solve the problems of high processing cost and large secondary eddy current loss of permanent magnet linear synchronous motors, etc. Achieve the effect of low processing cost, simple processing and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

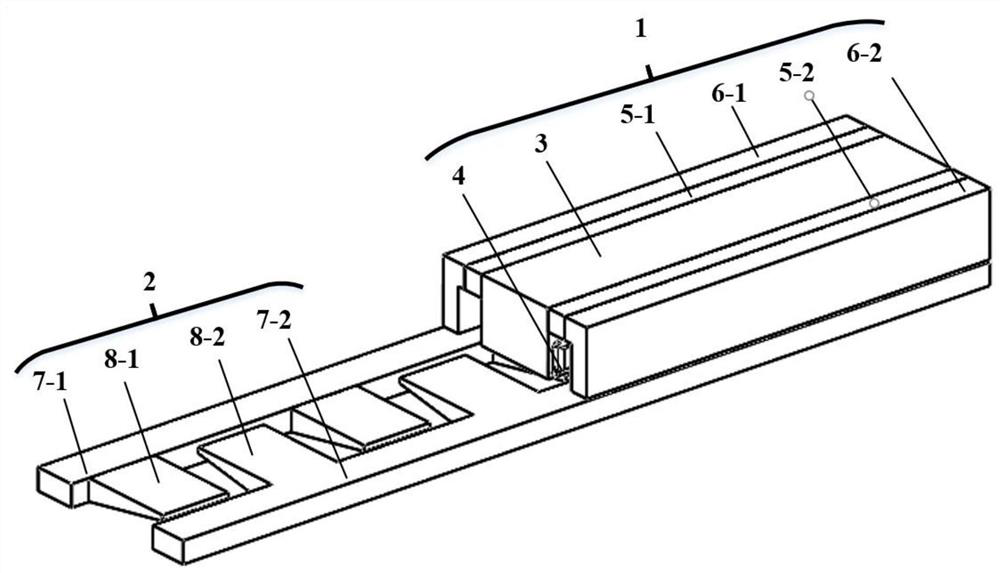

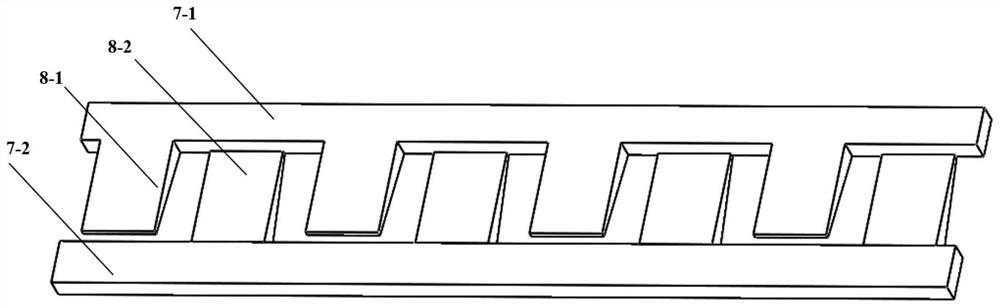

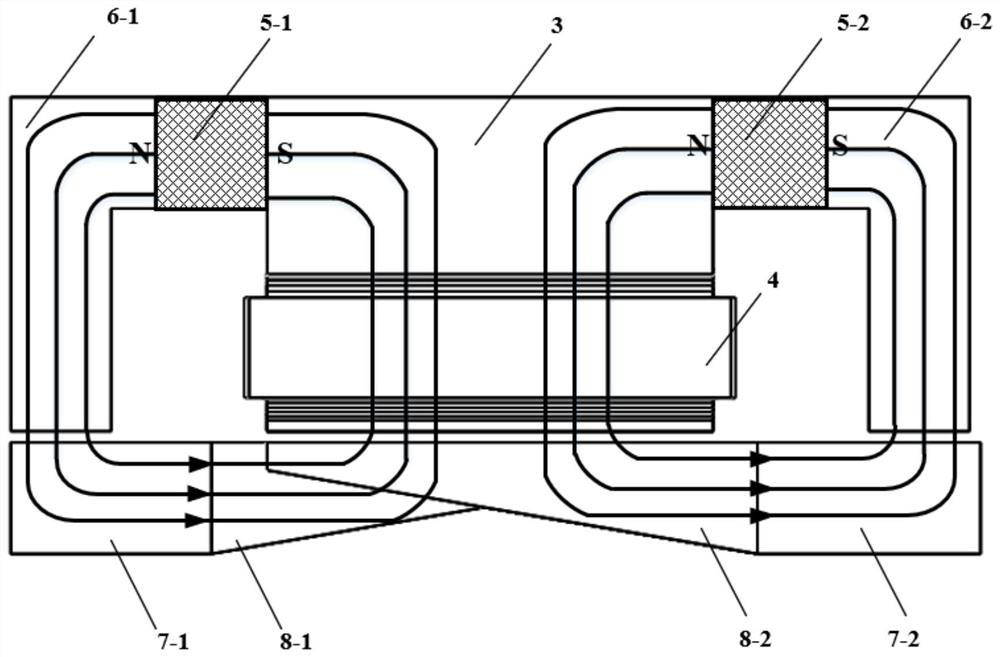

[0024] Such as figure 1 As shown, the unilateral homopolar permanent magnet linear synchronous motor provided by the present invention includes a primary 1, a secondary 2 and an air gap formed between the primary and the secondary. The number of slots of the primary iron core is 25, and the pitch of the primary armature winding 4 is 1, which is concentratedly wound on the primary iron core in a double-layer structure. The first permanent magnet 5 - 1 and the second permanent magnet 5 - 2 are arranged at both ends of the primary iron core 3 and are flush with the upper end of the primary iron core 3 . The first excitation core 6-1 and the second excitation core 6-2 are respectively arranged on the two ends of the first permanent magnet 5-1 and the second permanent magnet 5-2 and aligned. Such as figure 2 As shown, secondary 2 includes a secondary yoke core and an array of core teeth. The secondary yoke core includes a first secondary yoke core 7 - 1 and a second secondary y...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap