Silage harvesting system and silage harvester

A technology of silage and frame, which is applied in the direction of harvesters, harvesting platforms, agricultural machinery and implements, etc. It can solve the problems of poor material handling capacity, etc., achieve the effect of long throwing distance, increase feeding amount, and realize the effect of front and rear positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

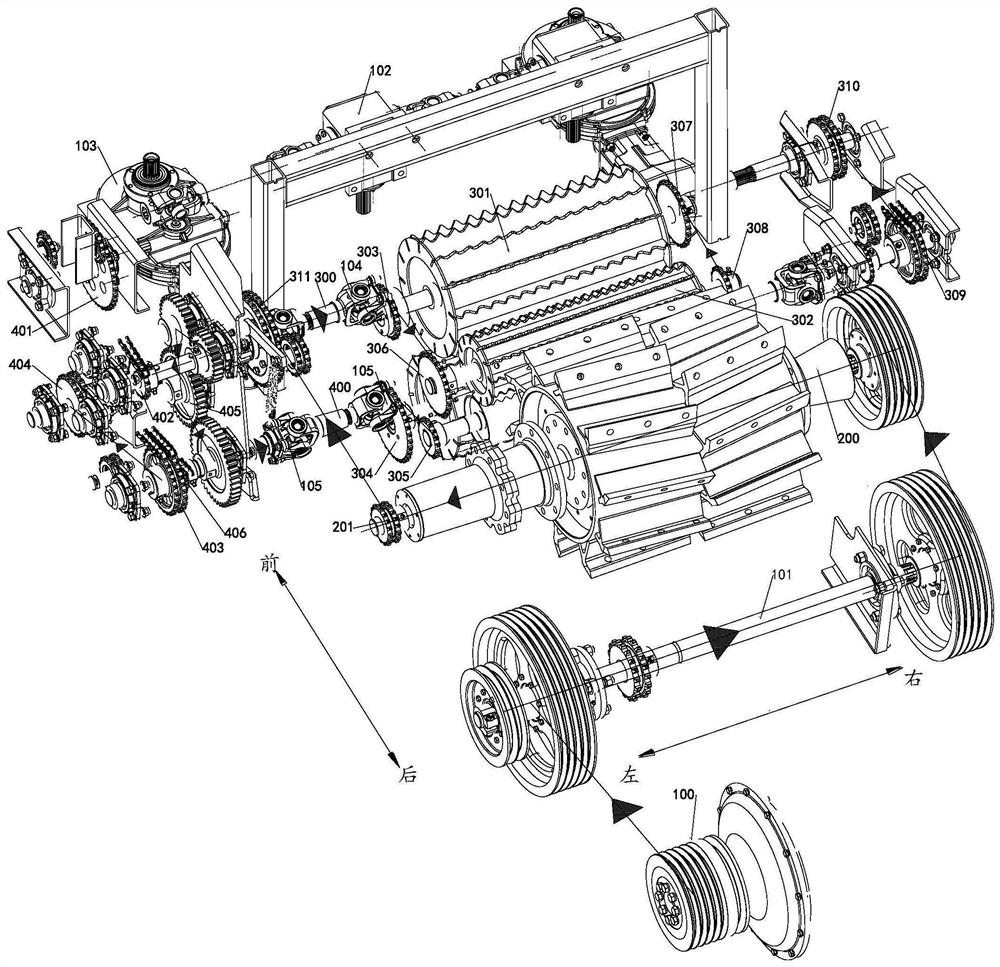

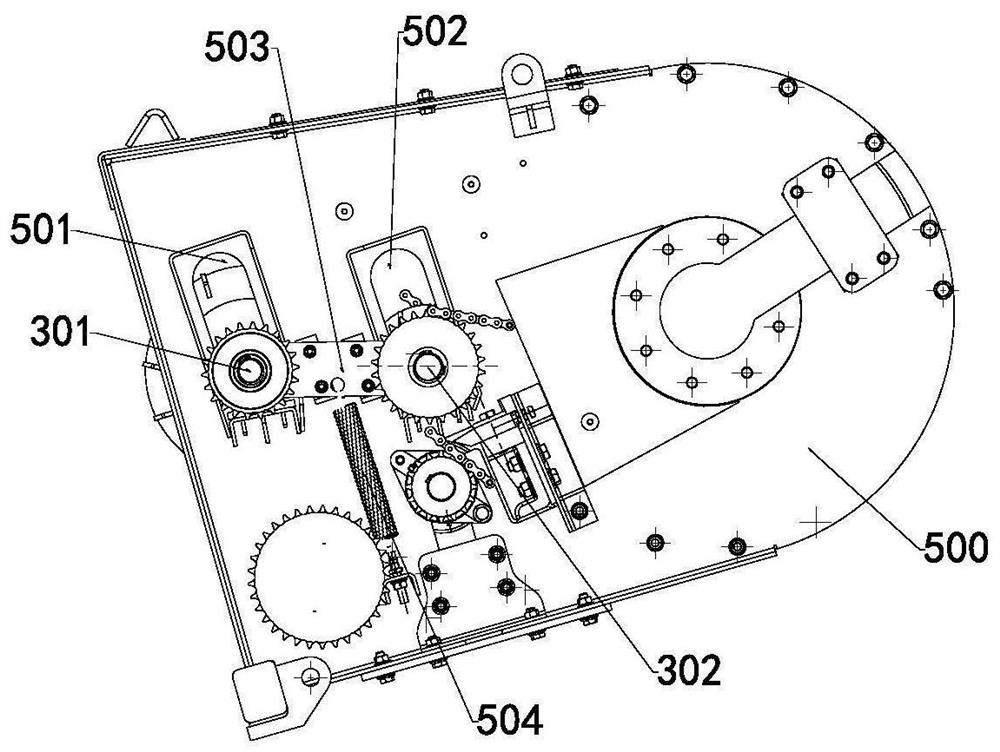

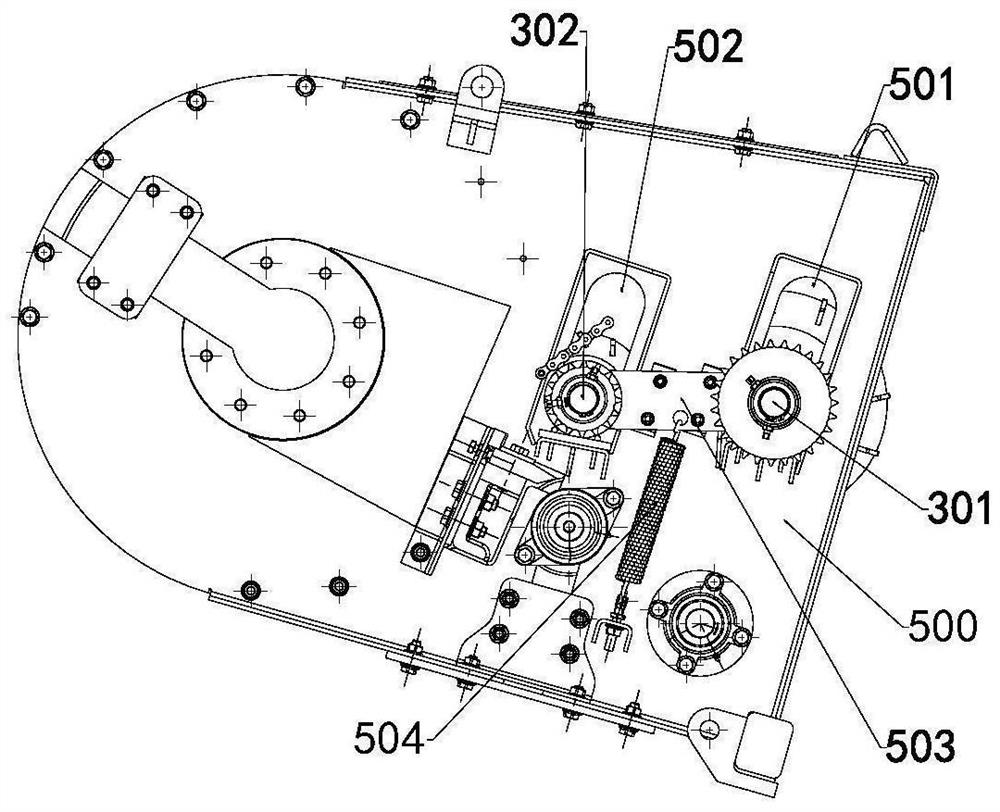

[0064] Such as Figure 1 to Figure 6 As shown, a kind of silage harvesting system of the present embodiment comprises frame 500 and silage header 810 installed on frame 500, conveying module, feeding module 312, chopping module 202, throwing module 811 and throwing barrel 812, the conveying module is located at the rear side of the silage header 810 and transports the harvested crops backwards, the feeding module 312 is located at the rear side of the transporting module and feeds the crops backwards, the chopped The module 202 is located at the rear side of the feeding module 312 and sends the fed crops to the throwing module after being chopped. The throwing cylinder 812 is installed on the rear side of the throwing module 811. The module 811 is located at the rear side of the shredding module 202 and throws the shredded material through the throwing cylinder 812 . It can be thrown into the grass collecting box 813 on the rear side of the silage harvesting system by the thr...

Embodiment 2

[0091] Such as Figure 5 As shown, a kind of green and yellow silage harvester of the present embodiment includes the silage harvesting system, and also includes a fringe harvesting platform 800, and the bottom of the fringe harvesting platform 800 is connected to the silage header by U-shaped bolts 804. On the frame 500 of 810, the rear side top of the ear harvesting platform 800 is connected with the frame 500 of the silage header 810 through the first adjustment pull rod 805, and the bottom middle position of the ear harvesting platform 800 is adjusted by the second adjustment. The pull rod 806 is connected with the frame 500 of the silage header 810; the bottom of the front end of the ear picking header 800 is provided with a plurality of mounting plates 803, and each of the mounting plates 803 is respectively provided with at least one U-shaped Bolts 804 , both ends of the U-shaped bolts 804 are respectively locked and fixed on the installation plate 803 by nuts.

[0092...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com