A compound methanol evaporator

A methanol evaporator and composite technology, which is applied in the direction of evaporator accessories, evaporation, spray evaporation, etc., can solve the problems of lower methanol evaporation efficiency, the inability to change the methanol contact surface of the heat pipe, and increase the production cost, so as to reduce the production cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

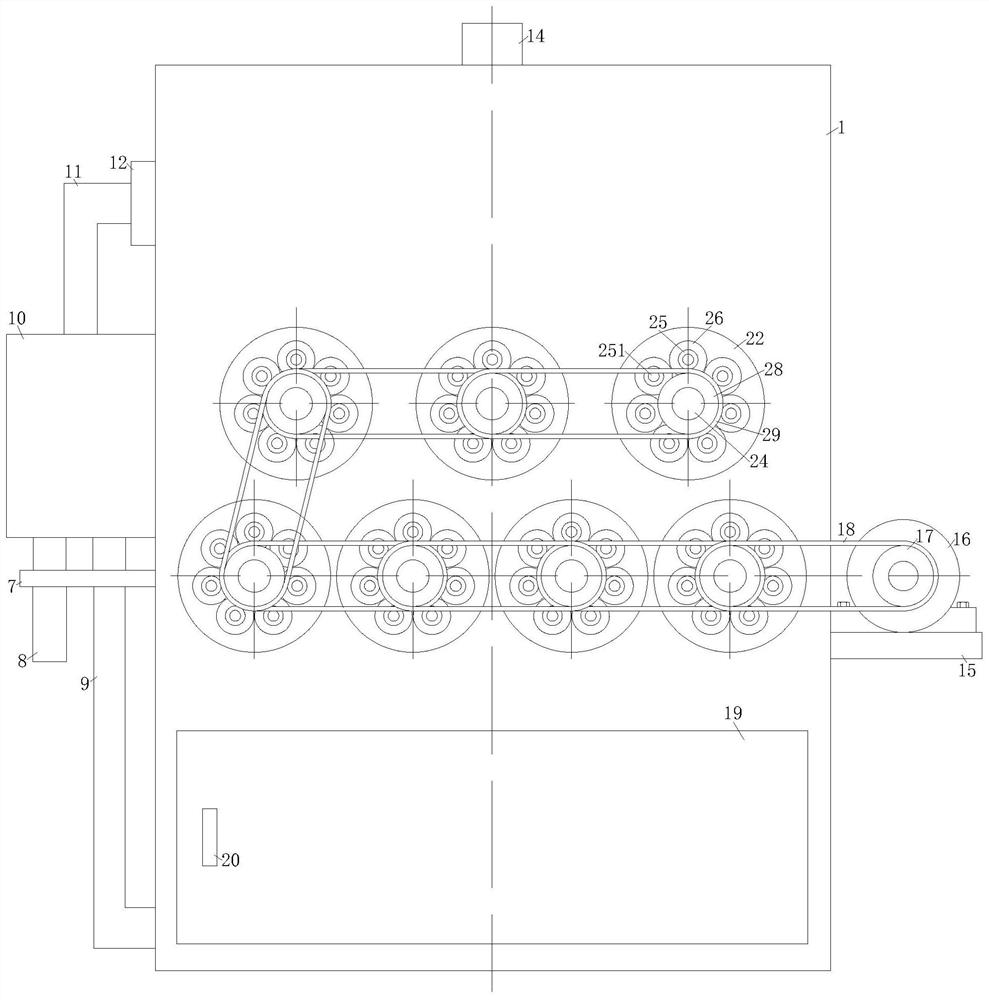

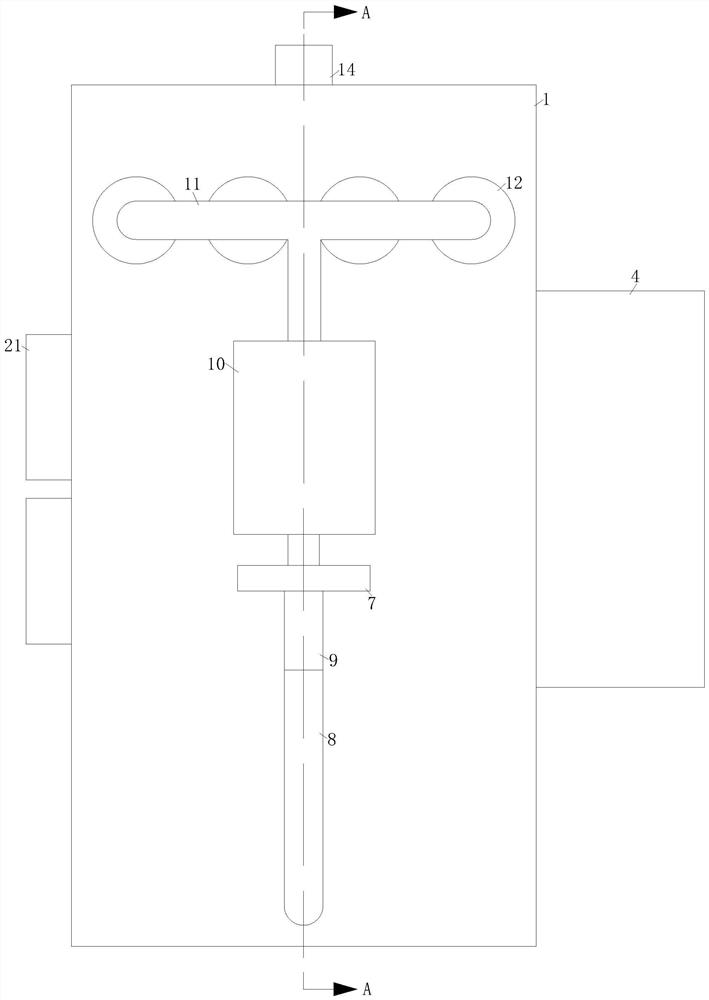

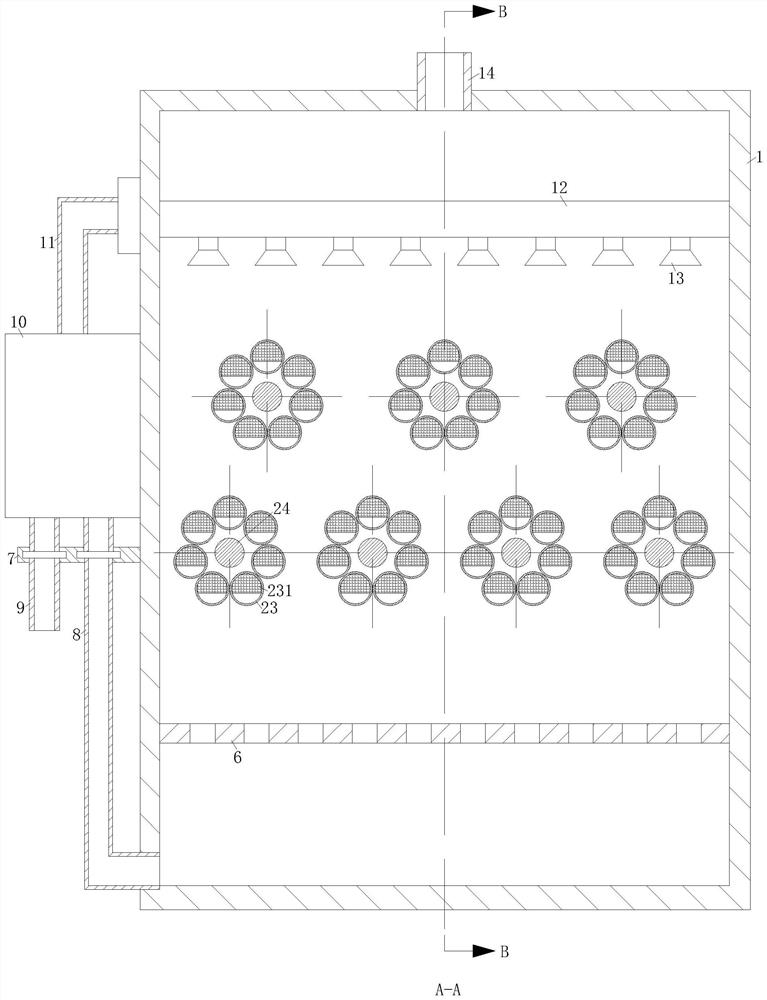

[0038] As an embodiment of the present invention, the evaporation mechanism 2 includes the first fixed block 21, the second fixed block 22, the heating pipe 23, the rotating shaft 24, the connection rod 25, the first -level gear 26, the second -level gear 27, the first -class leather wheel wheel 28 and first -class belt 29, the outer surface fixing of the back end of the box 1 has the first fixed block 21, the front surface of the box 1 of the box 1 has a second fixed block 22, the first fixed block 21 and the second fixed block 22 The side near the box 1 has multiple grooves 211, and multiple grooves 211 ring is distributed on one side of the fixed block. The other end of the pilot 22 is connected to the inner wall of the groove 211, respectively. The inner wall rotation of the groove 211 has a thermal conductance pipe 23, the heater 23 is close to the connection rod 25 of the one end of the second fixed block 22, and the connection rod 25 is 25, the connection rod 25 25 The othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com