Patents

Literature

33results about How to "Avoid lowering production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

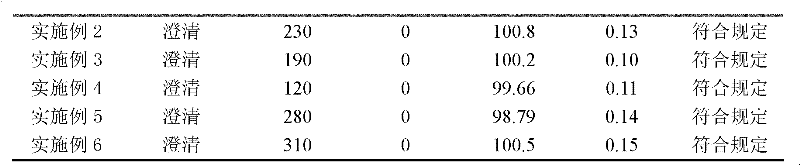

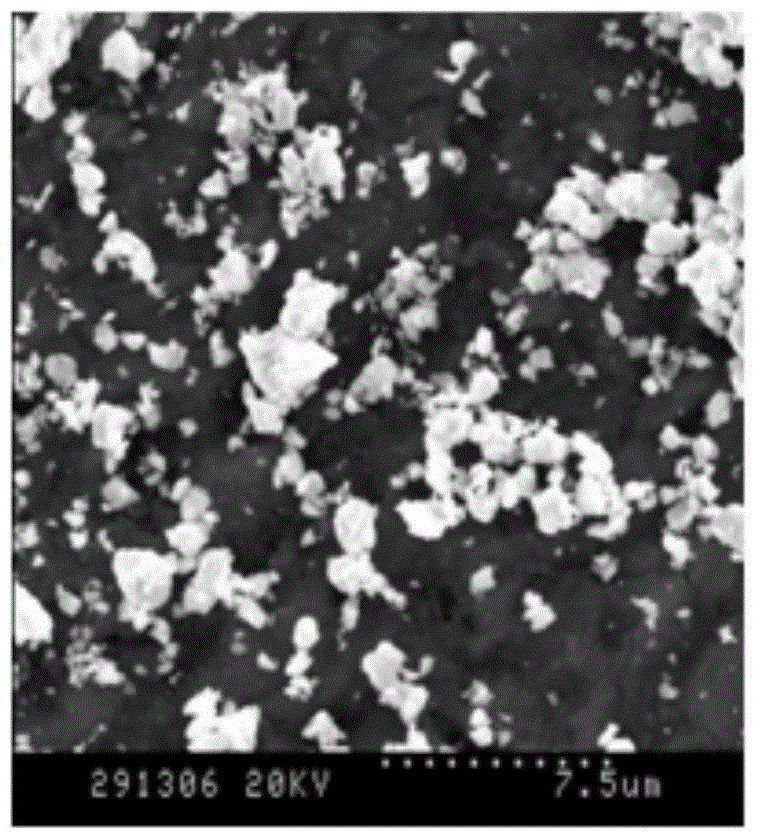

High specific gravity tungsten alloy material and preparation method thereof

The invention provides a high specific gravity tungsten alloy material and a preparation method thereof. The preparation method comprises the following steps: 1) ball-milling tungsten powder to prepare modified tungsten powder; 2) ball-milling mixed nickel powder and iron powder to prepare a nanocrystalline ferronickel solid solution; 3) mixing the modified tungsten powder and the nanocrystalline ferronickel solid solution in a weight ratio of 93:7 and compressing to form a blank; 4) liquid sintering the blank to prepare a sintered blank with the relative density of 93.9-99.8%; 5) mixing superfine graphite powder and nano silicon dioxide powder in a weigh ratio of (60-90):(20-40) and ball-milling, and compressing till the relative density is 80-90% and preparing a lubricating medium; and 6) putting the sintered blank in the lubricating medium for thermal hydrostatic extrusion and carrying out thermal treatment on the sintered blank after thermal hydrostatic extrusion to prepare the high specific gravity tungsten alloy material. The strength of the high specific gravity tungsten alloy material prepared by the method is greatly improved while good ductility is still maintained.

Owner:HARBIN INST OF TECH +1

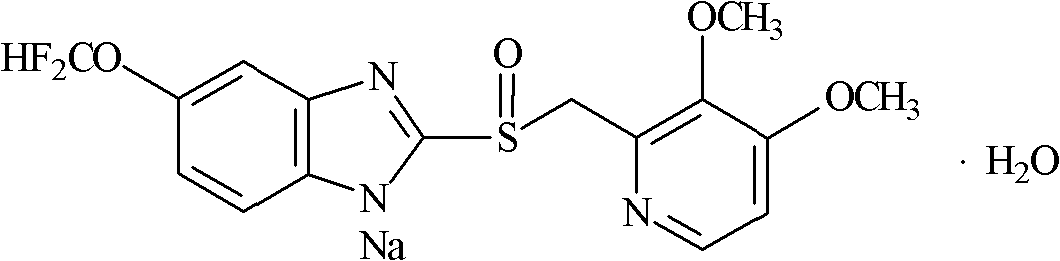

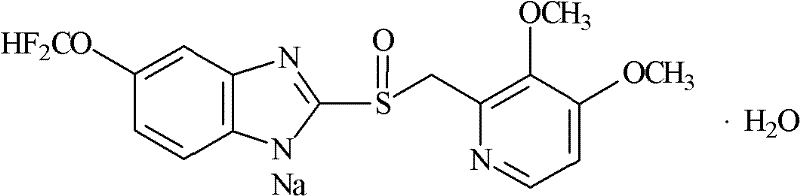

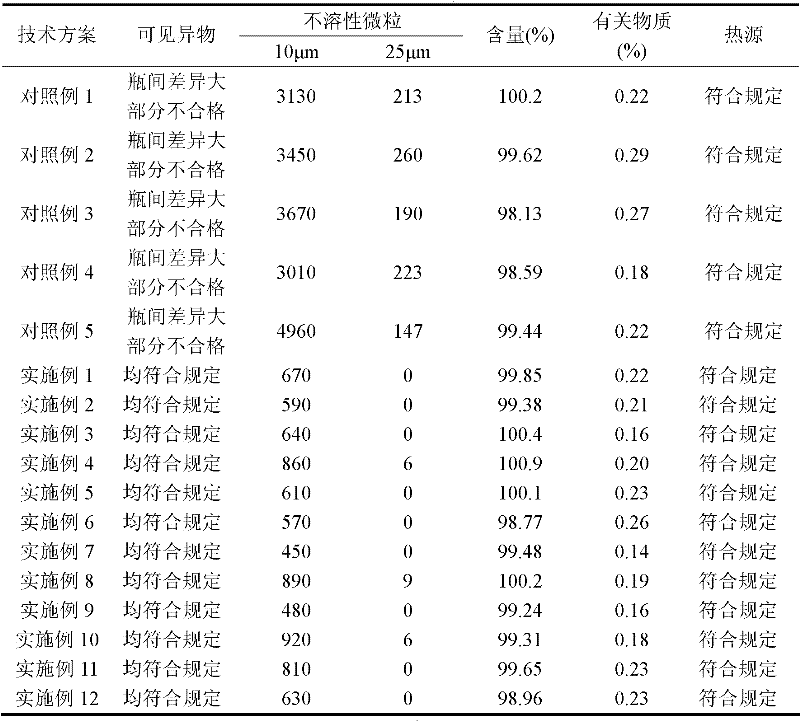

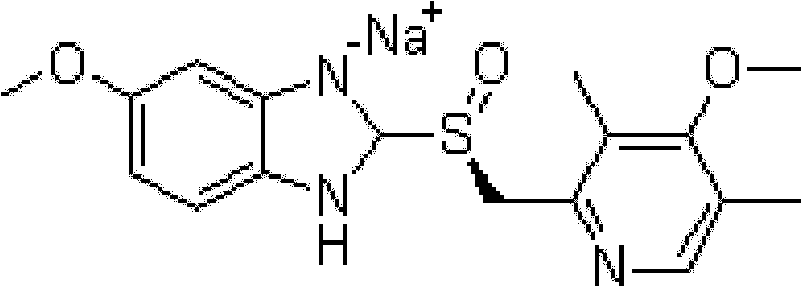

S-pantoprazole sodium composite for injection and preparation method thereof

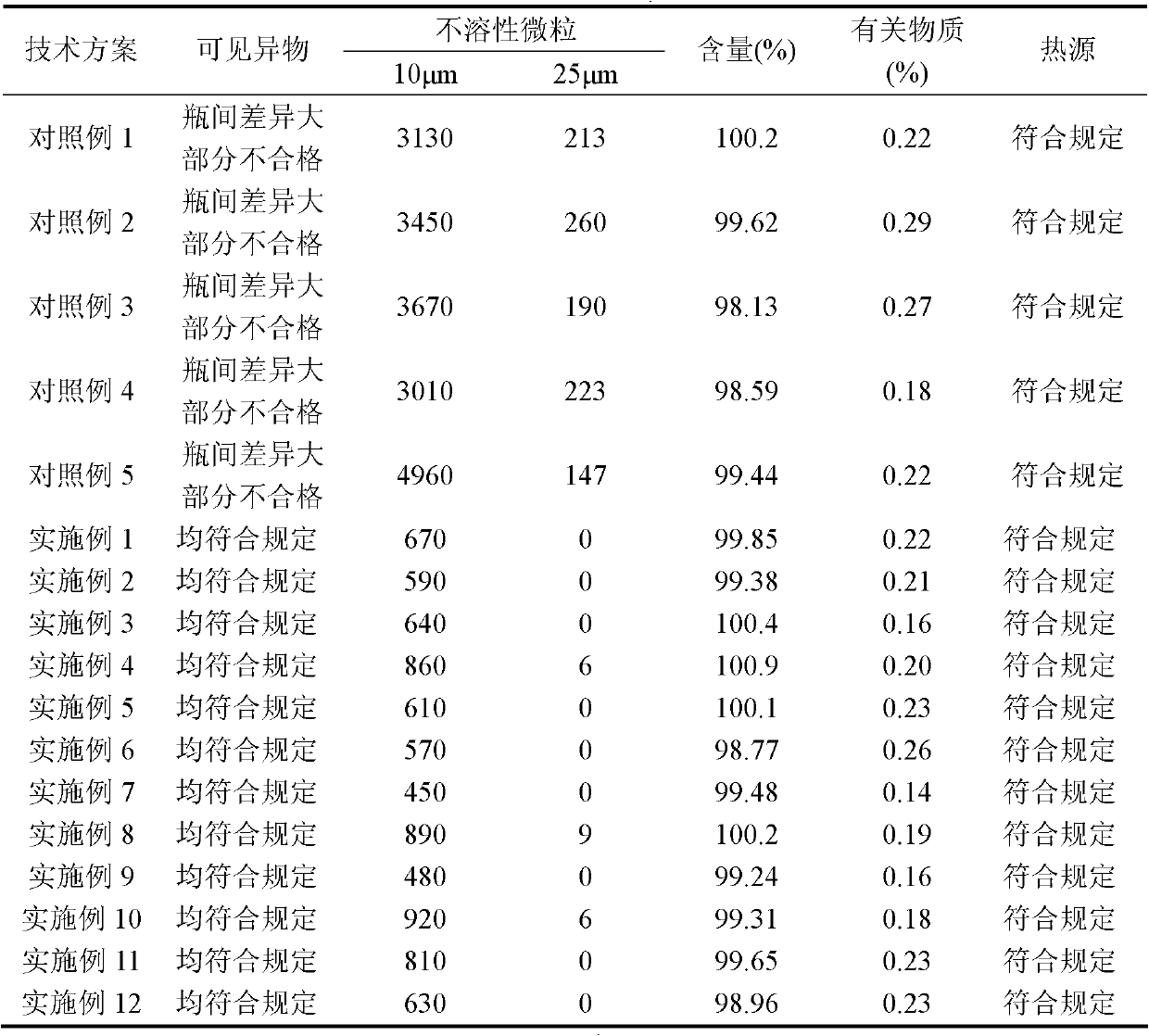

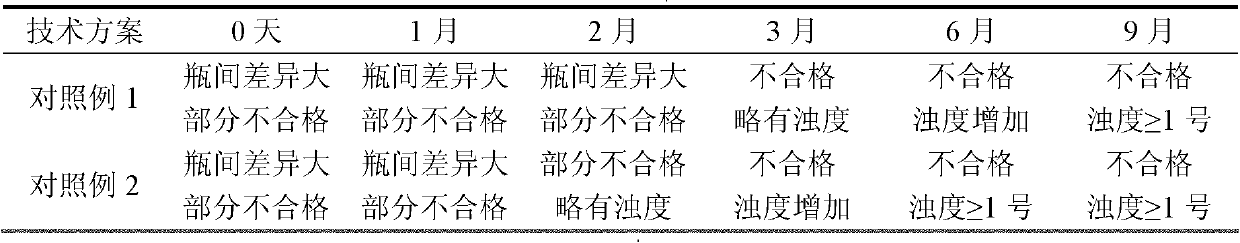

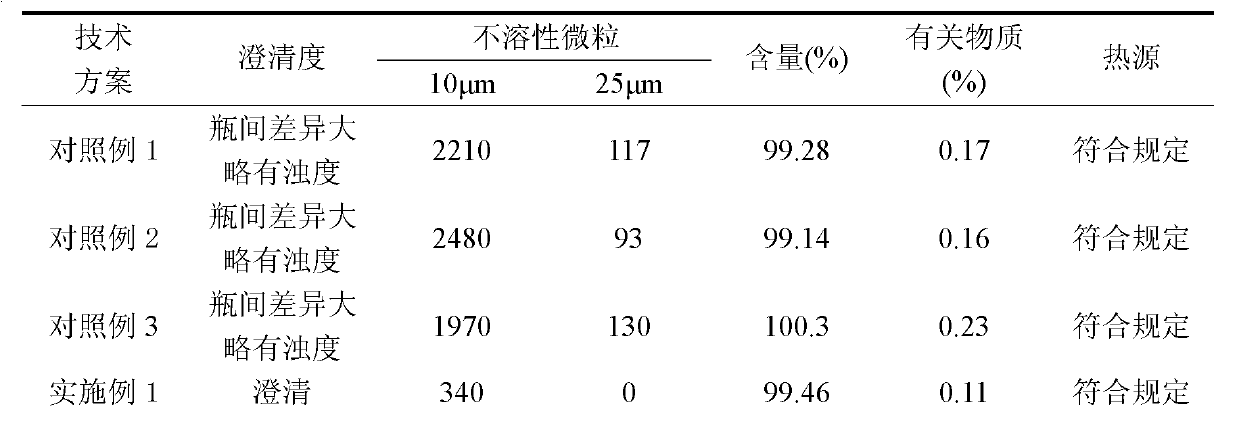

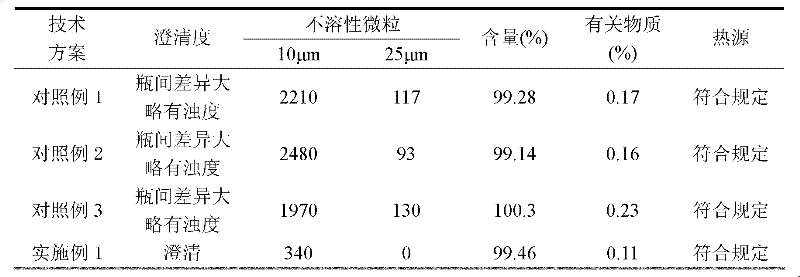

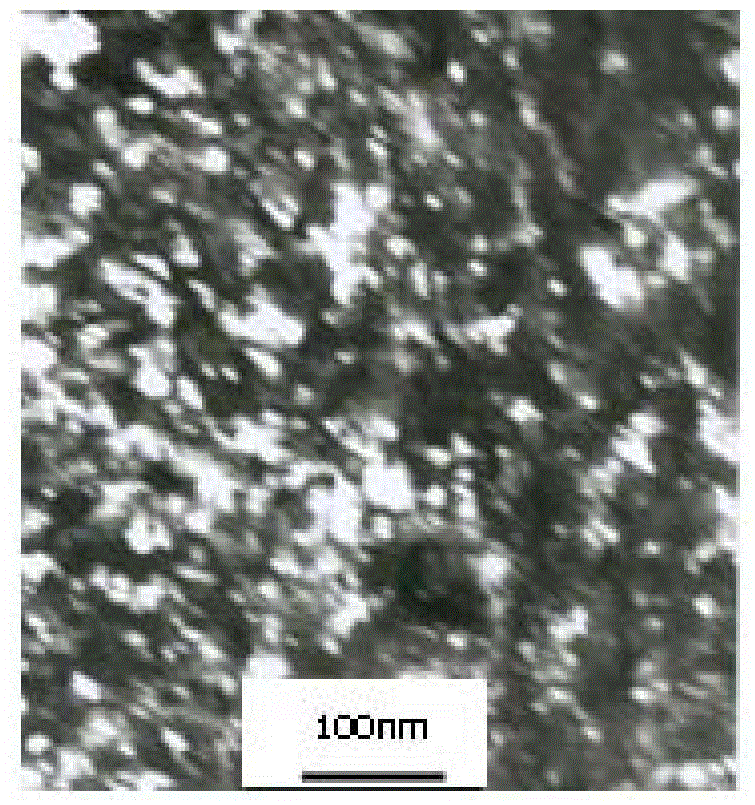

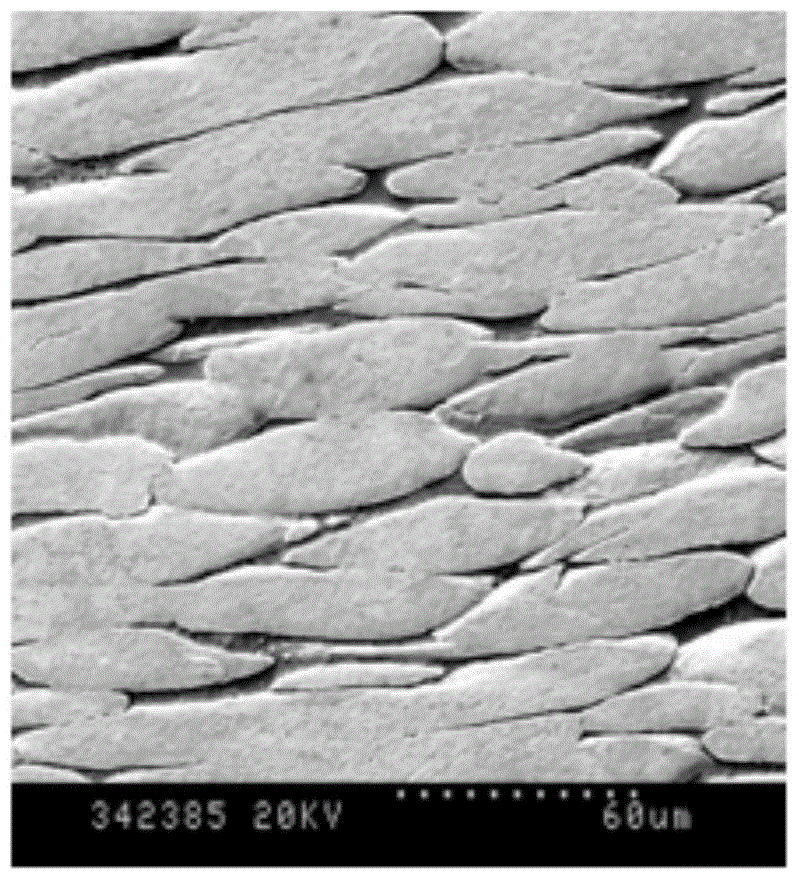

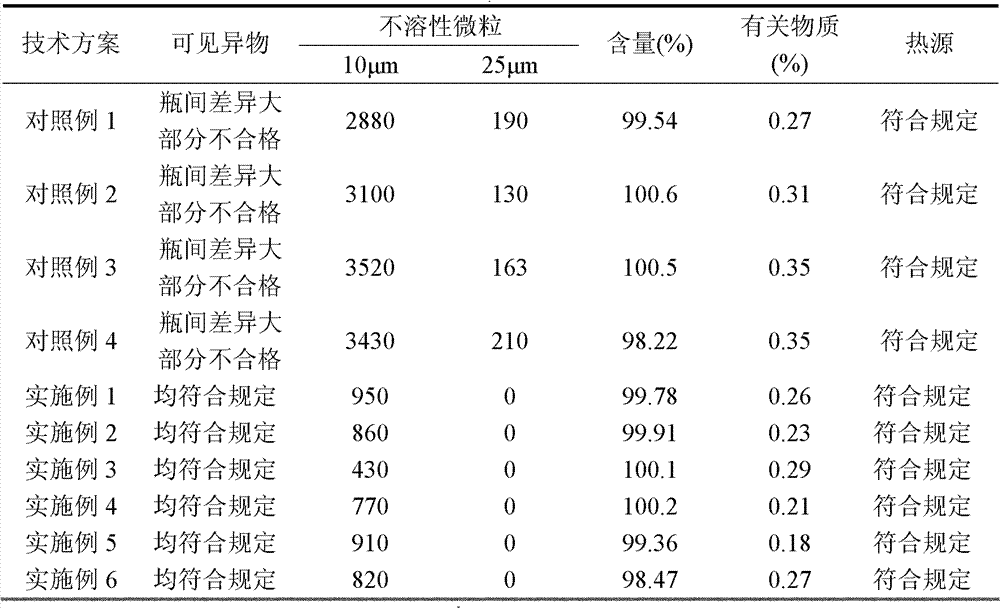

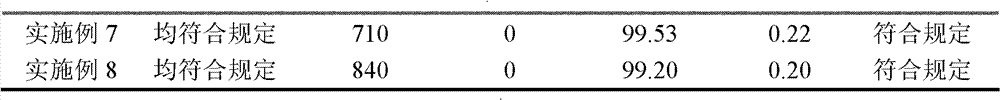

ActiveCN102000034AImprove uniformityInhibition releasePowder deliveryOrganic active ingredientsEthylenediamineForeign matter

The invention provides an S-pantoprazole sodium composite for injection, which is prepared through a method comprising the following steps of: (1) preparing liquid medicine: selecting S-pantoprazole sodium and edetic acid or edetate as raw materials, wherein the weight ratio of the S-pantoprazole sodium and the edetic acid or the edetate is 1:0.01-0.1; weighing a right amount of the raw materials, placing into a preparation tank, adding water for the injection till the weight of a solution is 11.82-118.2 times more than that of the S-pantoprazole sodium, stirring for dissolution, uniformly mixing, and regulating the pH value of the solution at 10.0-12.5; (2) finishing active carbon; (3) absorbing; (4) carrying out aseptic filtration and split charging; and (5) carrying out vacuum freeze drying so as to obtain the S-pantoprazole sodium composite for the injection. The S-pantoprazole sodium composite for the injection and the preparation method thereof can both ensure that product heat sources, visible foreign matters and insoluble particles meet the requirements of injections for the injections, i.e. S-pantoprazole sodium preparing liquid medicine which has higher pH.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Essential oil press device

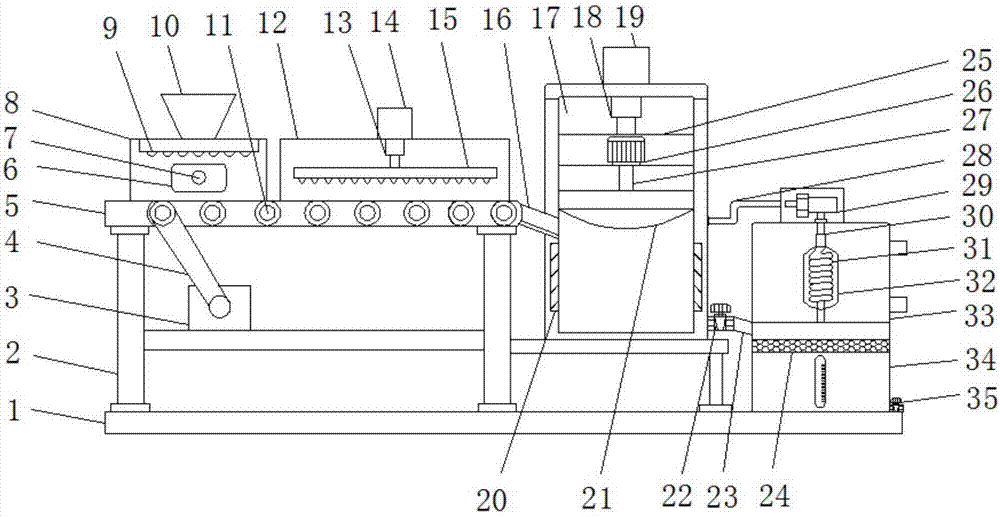

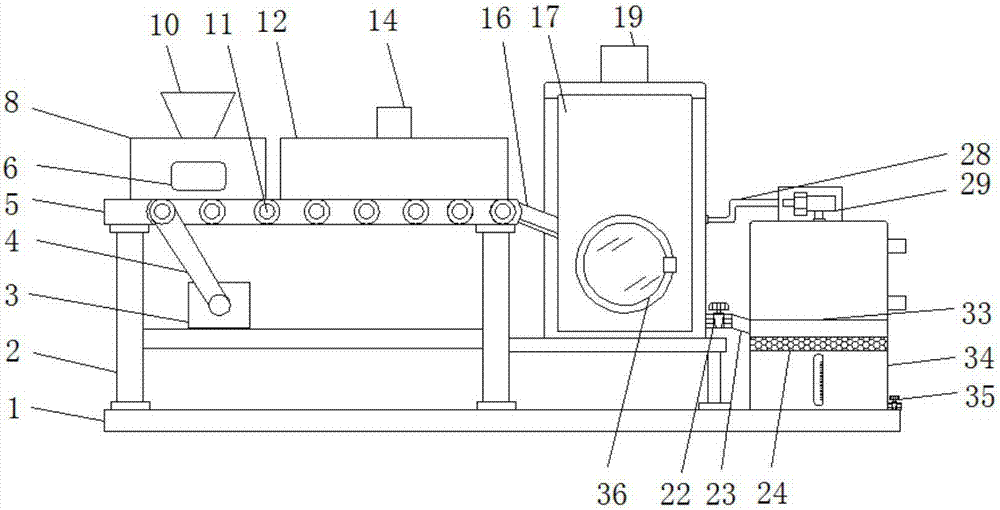

PendingCN107365632AImprove crushing efficiencyIncrease profitEssential-oils/perfumesEngineeringFuel tank

The invention discloses an essential oil pressing device, which comprises a base, a support, a dust removal box, a pressing box and a condensation box. A support is installed on one side of the top of the base, and an oil storage tank is installed on the other side of the top of the base. A condensation box is installed on the top of the oil tank, a squeeze box is installed on the side close to the oil storage tank at the top of the support, and a hatch is arranged at the bottom of one end of the squeeze box, and a dust removal box is installed on the side far from the press box at the top of the support plate, A cutting and pressing box is installed on the side close to the pressing box at the top of the support plate. A condensation pipe is installed inside the condensation chamber. In the present invention, a dust extractor and an ultraviolet lamp are installed at the feeding port, the dust extractor can remove the dust remaining on the plants, and the ultraviolet lamp can sterilize the plants, effectively avoiding the dust and bacteria remaining on the plants from being mixed with the plant during pressing. Mixed into the plant essential oil, causing the quality of the plant essential oil to decrease.

Owner:重庆枫铃农业科技发展有限公司

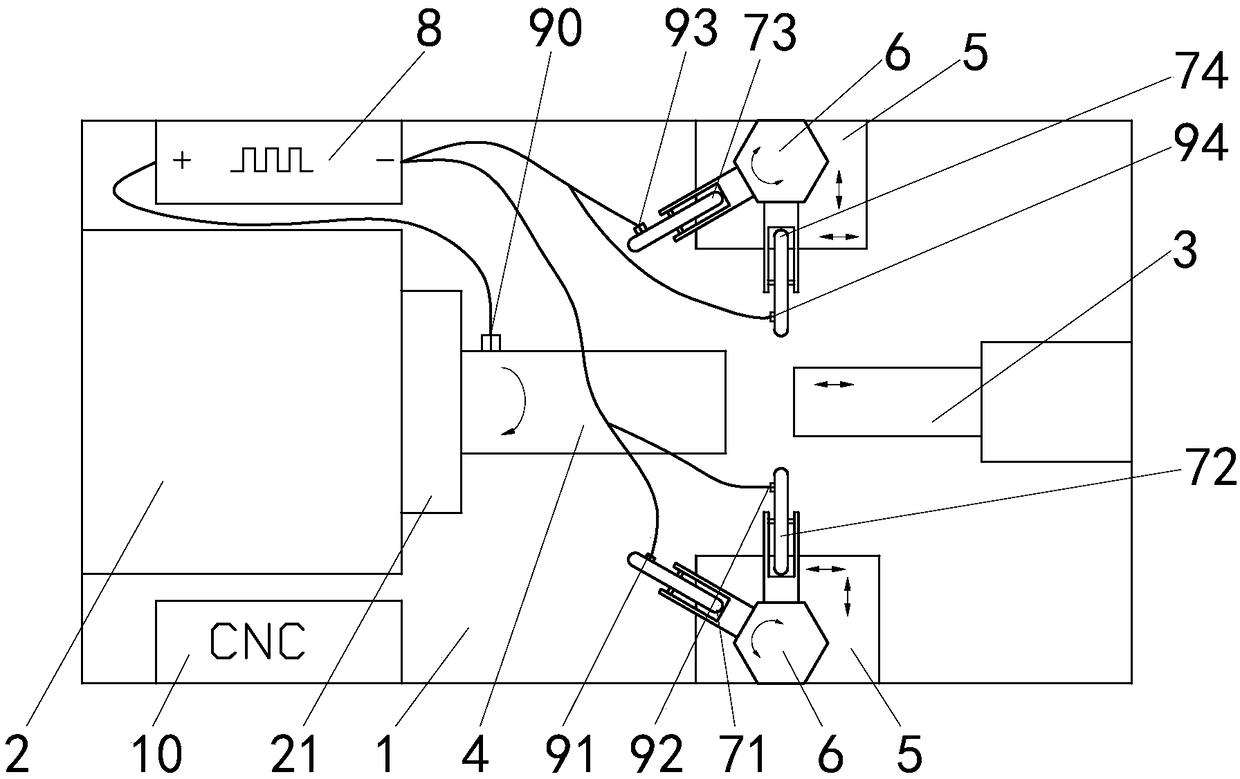

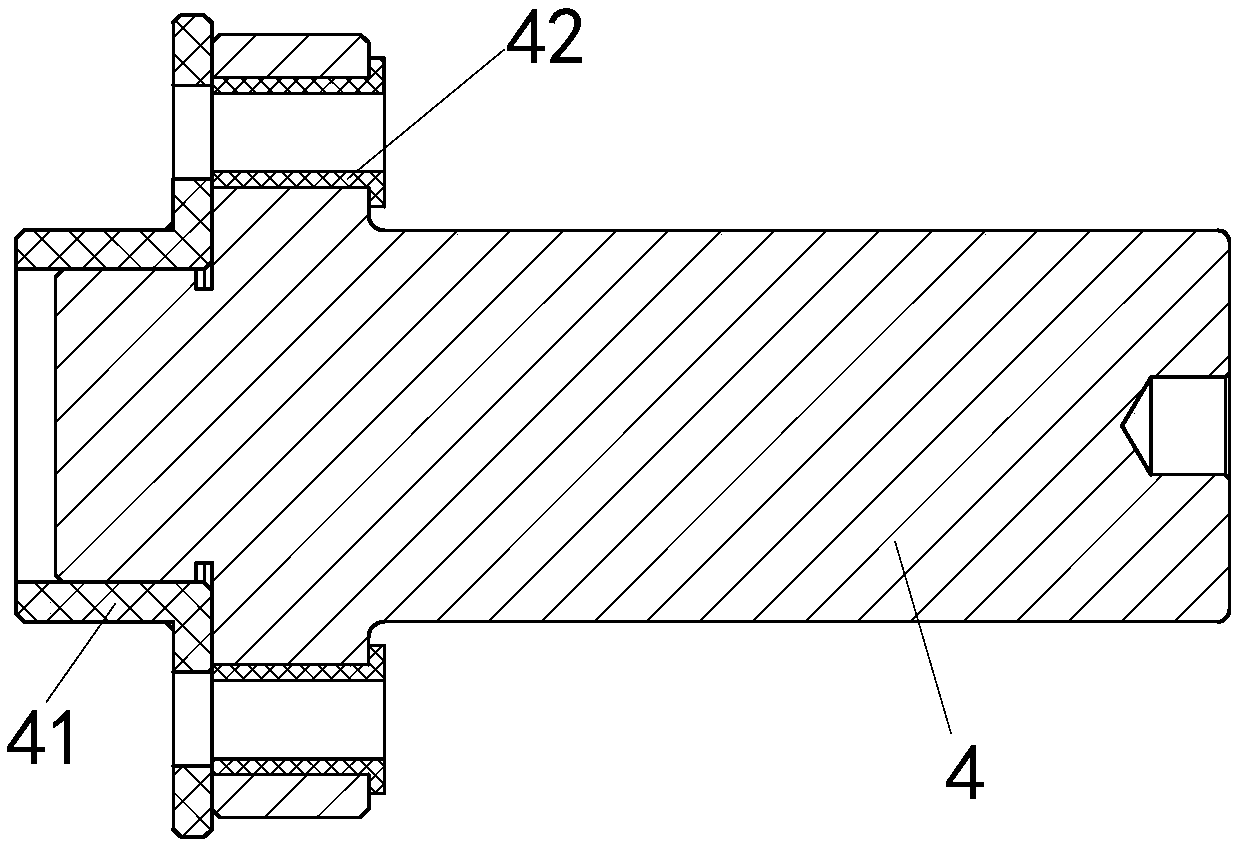

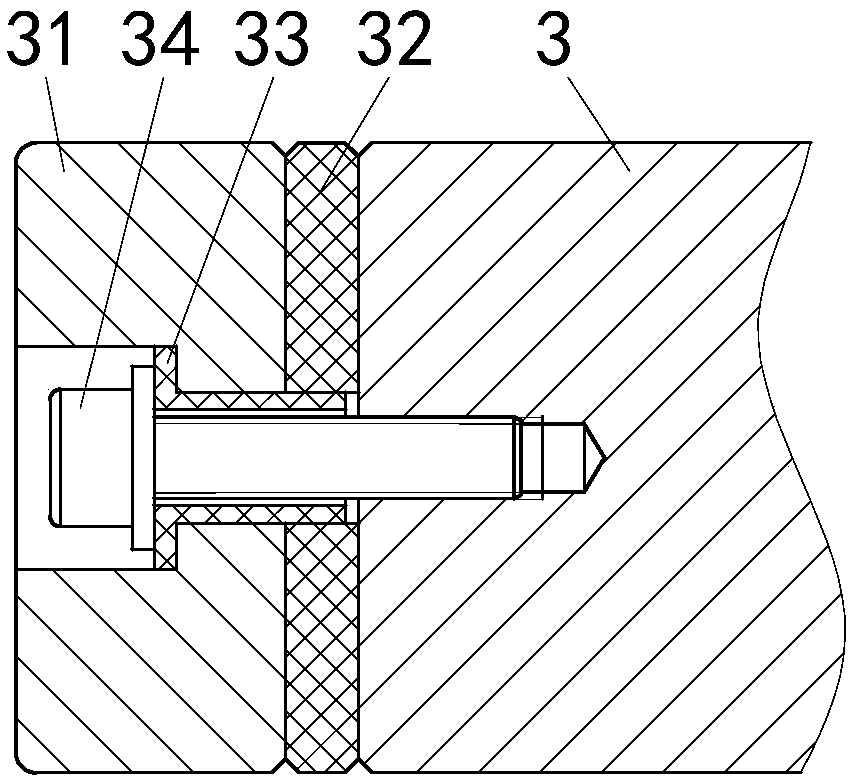

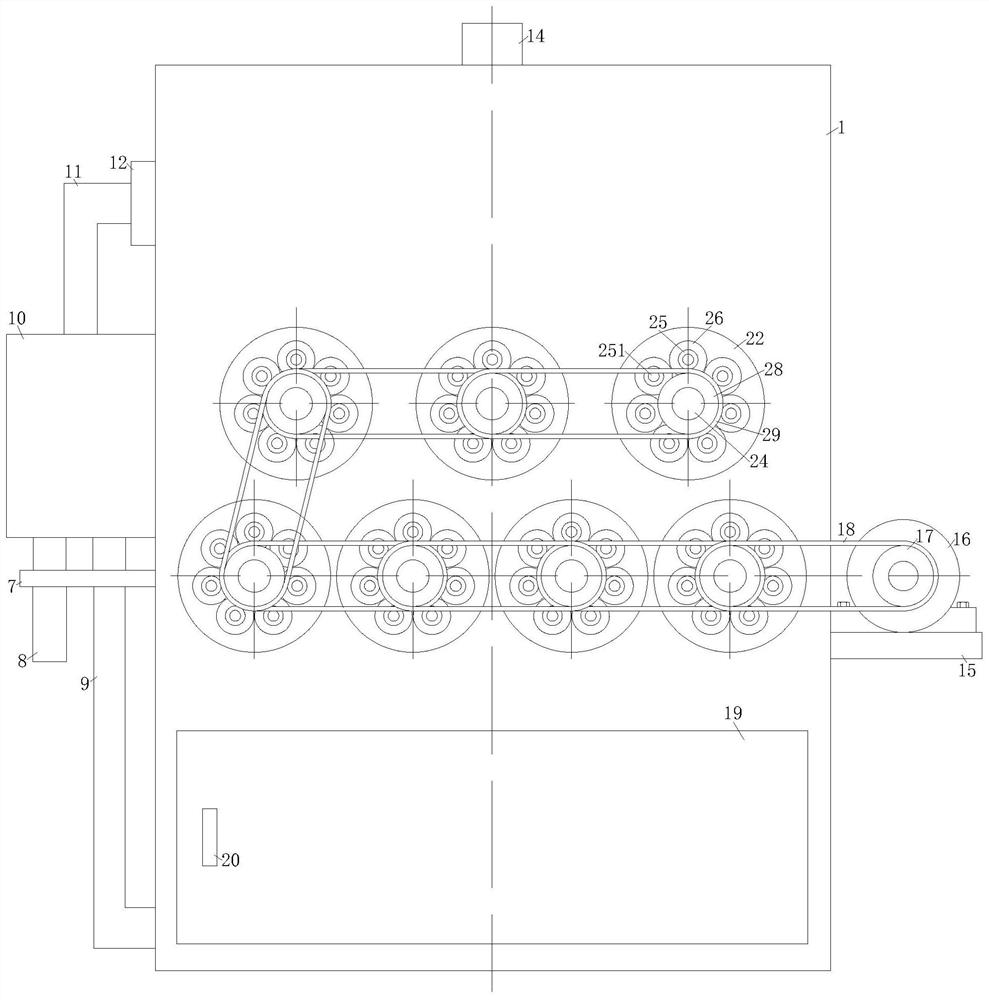

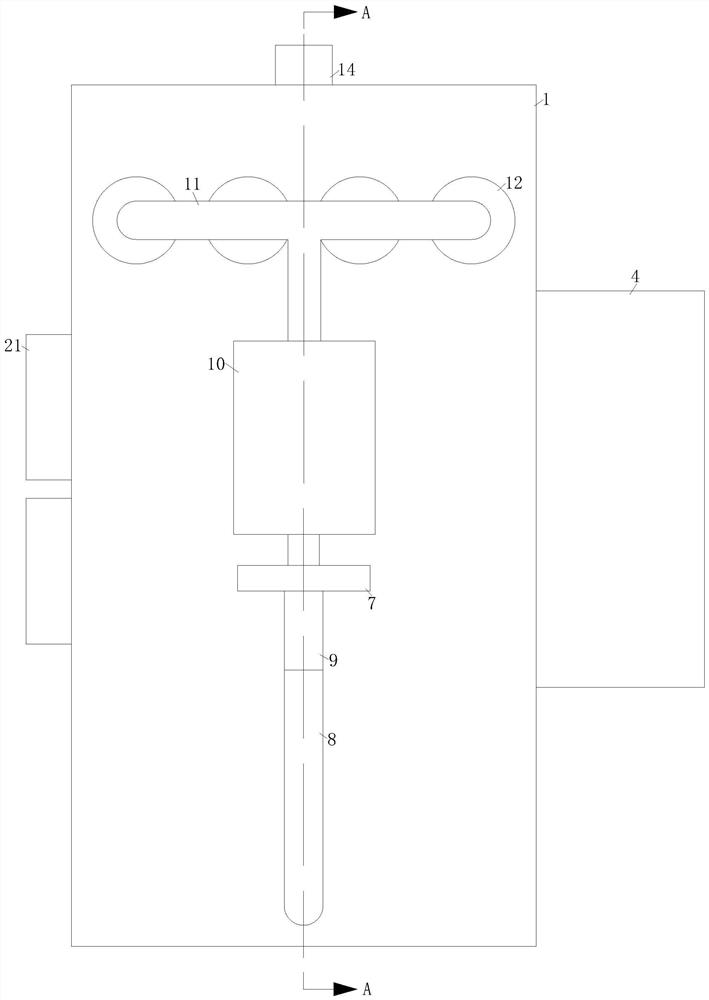

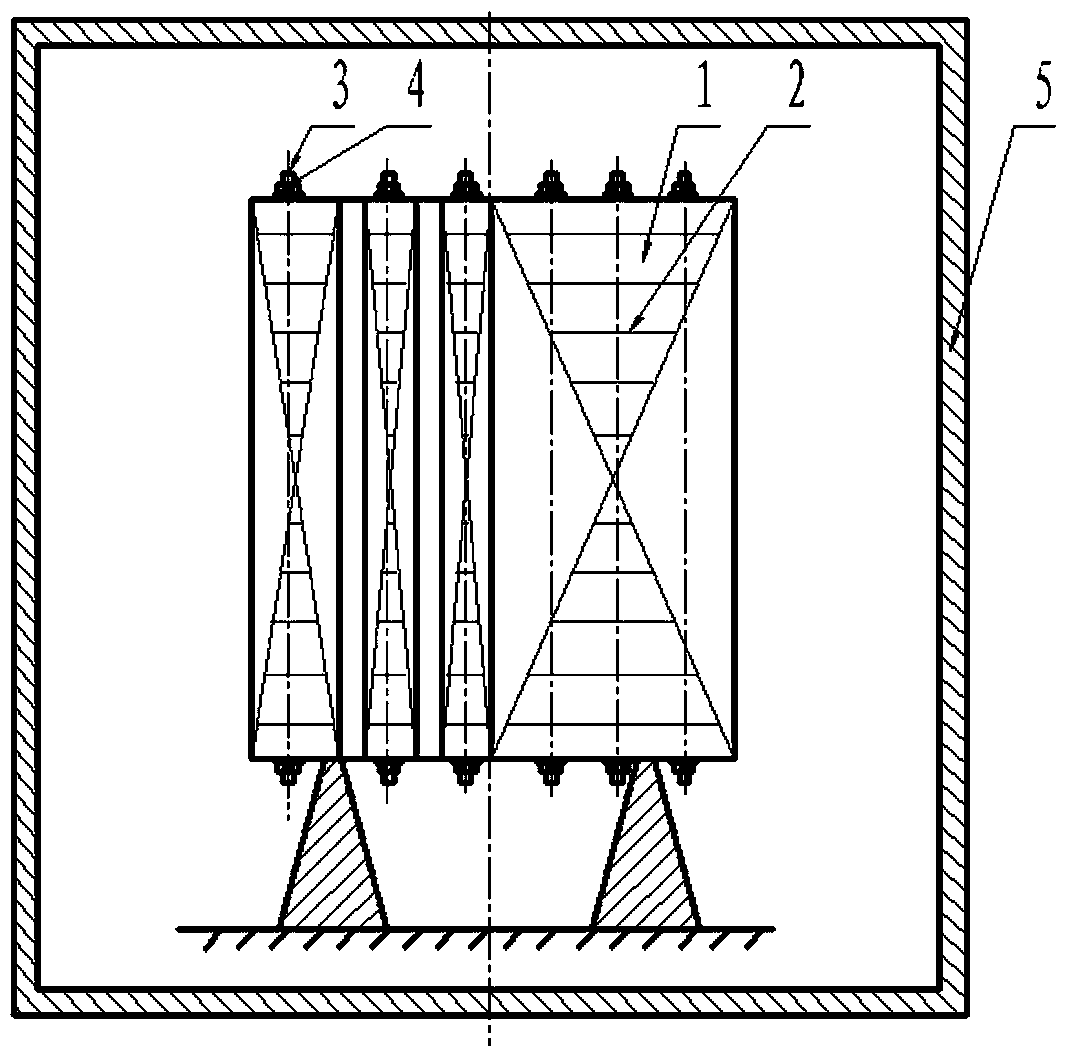

Electric pulse auxiliary spinning forming machine tool

The invention discloses an electric pulse auxiliary spinning forming machine tool. A machine tool body, a high energy pulse power source and a control unit are included. A headstock and a tail ejectorare fixed to the two ends of the machine tool body correspondingly. A main shaft of the headstock is provided with a core die. The center line of the main shaft, the center line of the core die and the center line of the tail ejector are in coincidence. Each of the two sides of the core die and the two sides of the tail ejector is provided with a movable platform capable of moving on the machinetool body. Each movable platform is provided with a rotary rotation wheel base. Rotation wheels are arranged on the rotation wheel bases. The positive electrode and the negative electrode of the highenergy pulse power source are connected with the core die and the rotation wheels through electric brushes. The contact faces of the electric brushes and the rotation wheels are in an opening circularring shape. The control unit conducts CNC over the motion of various components on the machine tool body. The high energy pulse current is applied between the core die and the rotation wheels, accordingly, the shortest current path is formed among the core die, a workpiece and the rotation wheels, the current utilization rate is increased, the spinning deformation area can be constantly limited at the part where the current density is the largest, and the electroplastic efficiency is improved to the maximum degree.

Owner:SOUTH CHINA UNIV OF TECH

S-pantoprazole sodium composite for injection and preparation method thereof

ActiveCN102000034BImprove uniformityInhibition releasePowder deliveryOrganic active ingredientsForeign matterEthylenediamine

The invention provides an S-pantoprazole sodium composite for injection, which is prepared through a method comprising the following steps of: (1) preparing liquid medicine: selecting S-pantoprazole sodium and edetic acid or edetate as raw materials, wherein the weight ratio of the S-pantoprazole sodium and the edetic acid or the edetate is 1:0.01-0.1; weighing a right amount of the raw materials, placing into a preparation tank, adding water for the injection till the weight of a solution is 11.82-118.2 times more than that of the S-pantoprazole sodium, stirring for dissolution, uniformly mixing, and regulating the pH value of the solution at 10.0-12.5; (2) finishing active carbon; (3) absorbing; (4) carrying out aseptic filtration and split charging; and (5) carrying out vacuum freeze drying so as to obtain the S-pantoprazole sodium composite for the injection. The S-pantoprazole sodium composite for the injection and the preparation method thereof can both ensure that product heat sources, visible foreign matters and insoluble particles meet the requirements of injections for the injections, i.e. S-pantoprazole sodium preparing liquid medicine which has higher pH.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

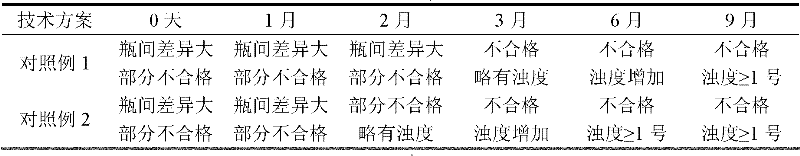

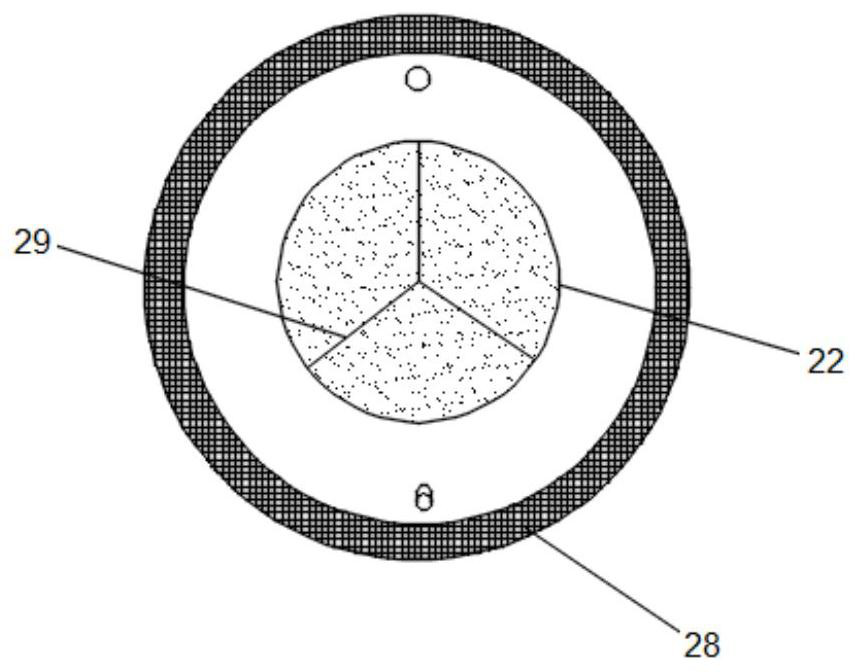

Method for preparing sinter by adding chromite into high-chromium type vanadium titano-magnetite

The invention relates to a method for preparing sinter by adding chromite into high-chromium type vanadium titano-magnetite. The method comprises the steps that the high-chromium type vanadium titano-magnetite, the chromite and other sintering materials are subjected to material mixing, material braising, material mixing, pelletizing, material distributing, igniting, sintering, crushing and screening, and the high-chromium type vanadium-titanium sinter is obtained. According to the method, the problem that material mixing is not even is effectively solved, the air permeability and the sintering rate of a sintered material in the sintering process are effectively increased, the situation that the sintering rate is decreased due to the fact that pellet materials with the grain sizes being large cannot be sintered thoroughly and completely is avoided, the production cost is effectively reduced, energy sources are saved, the sintering rate is further improved, and the yield is high. The prepared sinter has good air permeability in a softening-melting and dropping belt, the molten dropping performance is good, the yield is high, good metallurgical performance is achieved, and compared with the prior art, the recovery rates of Fe and Cr are increased greatly; and the method provides a theoretical foundation and a technological base for reasonably utilizing the Hongge vanadium titano-magnetite and the sinter prepared by adding the chromite into the high-chromium type vanadium titano-magnetite.

Owner:NORTHEASTERN UNIV

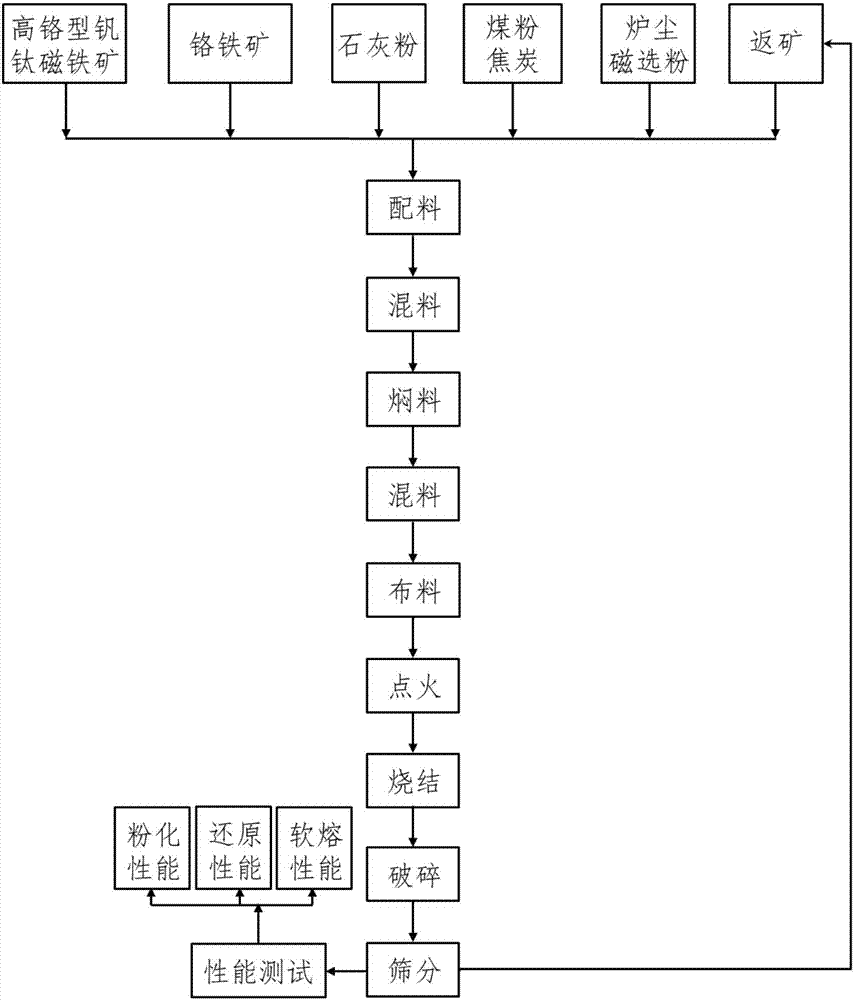

Zoledronic acid composition for injection and preparation method thereof

ActiveCN102000035AEliminate impacts on finished product qualityComply with injection requirementsPowder deliveryOrganic active ingredientsActivated carbonFreeze-drying

The invention provides a zoledronic acid composition for injection. The zoledronic acid composition for injection is prepared by the following steps of: 1) preparing medicinal liquid, namely selecting zoledronic acid and trisodium citrate as raw materials according to the weight ratio of the zoledronic acid to the trisodium citrate of 1:0.5-2, weighing a proper amount of the raw materials and placing the raw materials into a preparation tank, adding water for injection until the weight of the solution is 250 to 1,250 times that of the zoledronic acid, stirring the solution to dissolve the raw materials and mixing the raw materials uniformly and adjusting the pH value of the solution to be 4.0 to 6.0; 2) performing active carbon finishing; 3) performing adsorption; 4) performing aseptic filtration and subpackaging; and 5) performing vacuum freeze drying to obtain the zoledronic acid composition for injection. By the zoledronic acid composition for injection and the preparation method thereof, for injection of which the clarity is influenced by active carbon greatly, such as the zoledronic acid and the like, the heat source, the clarity and insoluble particles of the product can meet the requirements of the injection.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

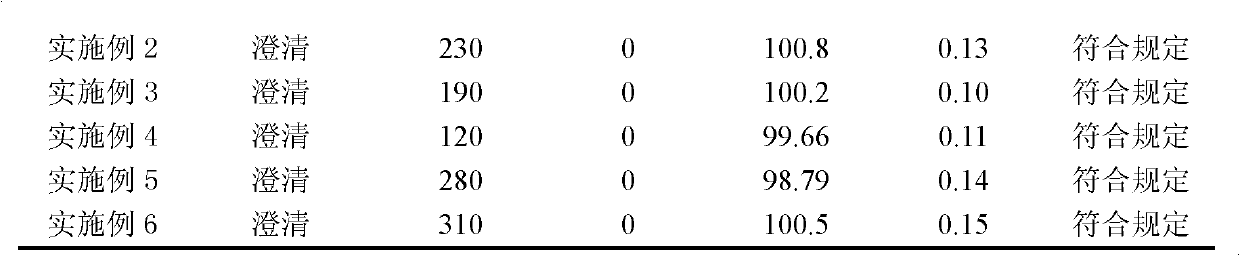

Lithium sulfide preparation method capable of realizing continuous production

ActiveCN114275742AEnhanced Solid ContactShort process routeCell electrodesAlkali metal sulfides/polysulfidesPhysical chemistrySulfidation

The invention discloses a lithium sulfide preparation method capable of realizing continuous production. According to the method, lithium sulfide is prepared by adopting a lithium sulfide precursor and a carbon high-temperature pyrolysis reduction method. The lithium sulfide precursor coats the carbon to promote the reaction, meanwhile, a sulfur atmosphere in the furnace is provided by adopting a sulfur powder evaporation mode, sulfur volatilization of the lithium sulfide precursor at a high temperature is inhibited, and flowing nitrogen is adopted for atmosphere protection. The method does not need vacuumizing or negative pressure protection, can be continuously carried out at normal pressure, and can realize continuous production by selectively using a roller kiln or a pushed slab furnace during amplification, so that the production cost of lithium sulfide is greatly reduced.

Owner:湖南恩捷前沿新材料科技有限公司

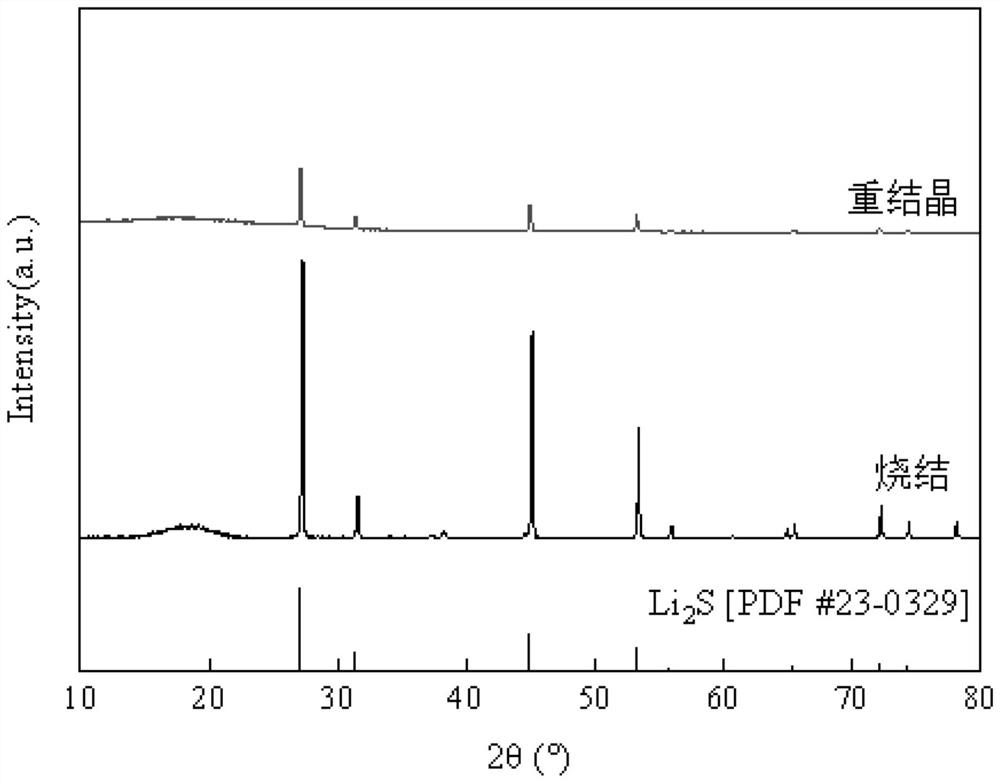

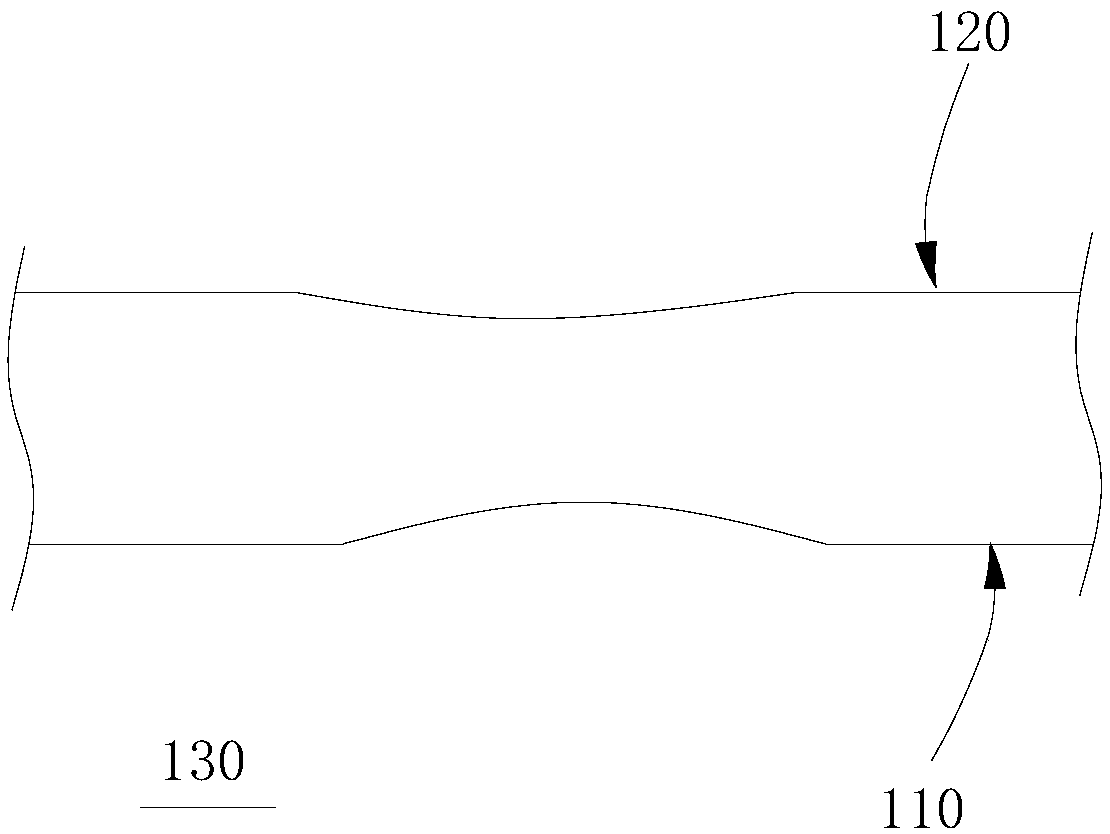

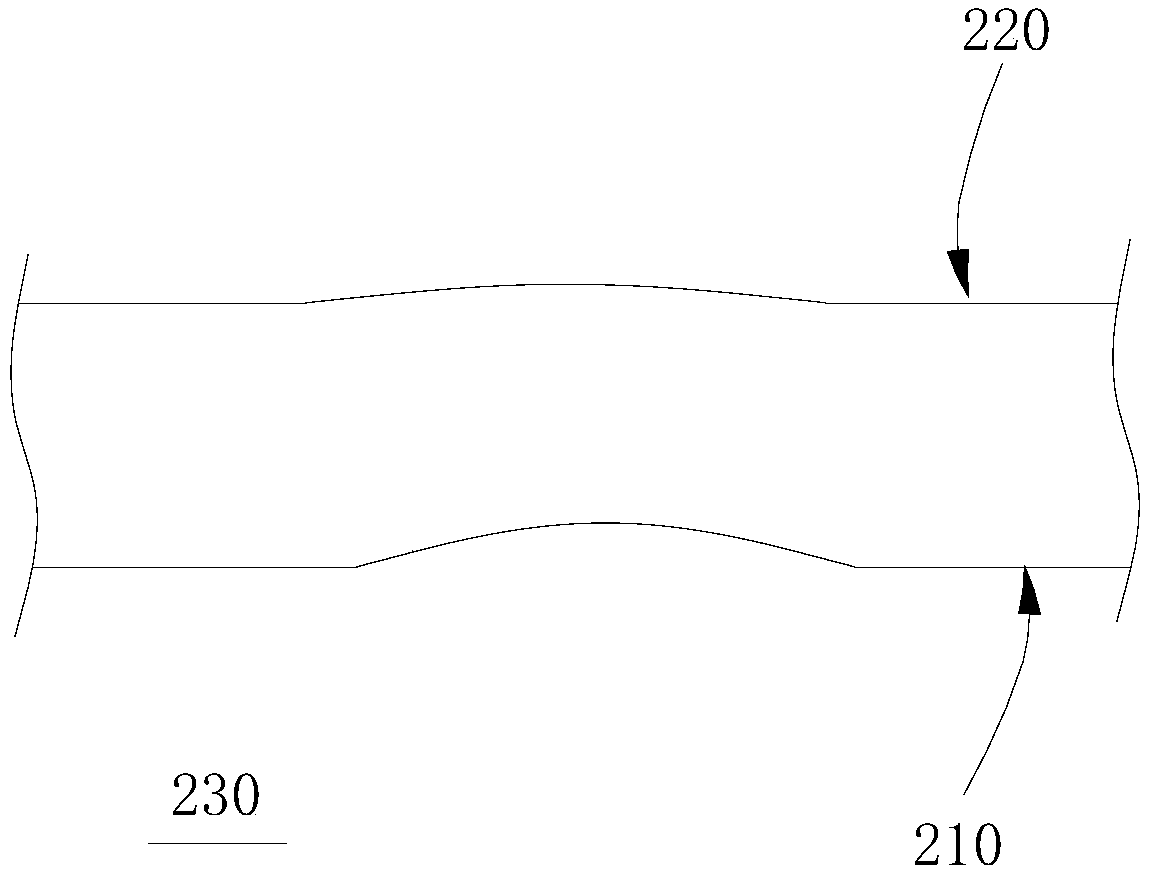

Laser carving method

ActiveCN108941919AReduce the waterproof effectAvoid lowering production costsLaser beam welding apparatusPlastic injection moldingEngineering

The invention relates to a laser carving method. The method comprises the following steps that S100, base materials are provided and machined to form an intermediate product; S200, a laser carving face and a machining face are determined, the machining face is opposite to the laser carving face, a laser carving area located on the laser carving face is determined, a machining area located on the machining face is determined, and the machining area corresponds to the laser carving area; S300, machining is carried out on the machining face so that the machining area can be concaved to a certaindepth; and S400, laser carving is carried out on the laser carving area on the laser carving face. After a middle frame is subjected to laser carving, the follow-up working procedure of assembling a display screen is not affected; when laser carving is carried out on the middle frame with a plastic injection molding function, the problem that the waterproof performance of the middle frame is lowered since the aluminum-plastic joint is cracked during planar shaping is avoided, the yield is improved, the production cost is greatly reduced, and an obvious significance is achieved in practical production. In addition, the shaping working procedure is not needed, and the time cost and the machining cost are saved.

Owner:GUANGDONG EVERWIN PRECISION TECH

Preparation method of dendrobium officinale lozenge tablet

InactiveCN107998288AReduce manufacturing costAvoid harmDigestive systemPharmaceutical non-active ingredientsSuperfine grindingWetting

The invention discloses a dendrobium officinale lozenge tablet and its preparation method. The preparation method comprises 1) pretreating fresh strips of dendrobium officinale, 2) taking the dried dendrobium officinale and carrying out superfine grinding, 3) placing the dendrobium officinale ultrafine powder in an ice grinding machine and mixing the dendrobium officinale ultrafine powder and water to obtain a dendrobium officinale raw liquid, 4) weighing the dendrobium officinale ultrafine powder and dendrobium officinale juice and carrying out uniform mixing to obtain a soft dendrobium officinale material, and 5) carrying out granulation, drying, tabletting and sterilization on the soft dendrobium officinale material through conventional processes. The dendrobium officinale lozenge tablet contains a dendrobium officinale ingredient, is free of auxiliary materials and is pure. The juice obtained through adding water into fresh dendrobium officinale and grinding the dendrobium officinale is used as a binder and a wetting agent for dendrobium officinale lozenge tablet preparation. The preparation method is free of accessories such as other binders and wetting agents, effectively guarantees the product health, is free of additives and alcohol as a wetting agent, greatly reduces a production cost and prevents additive eating damage.

Owner:龙里县泽洋生态科技有限公司

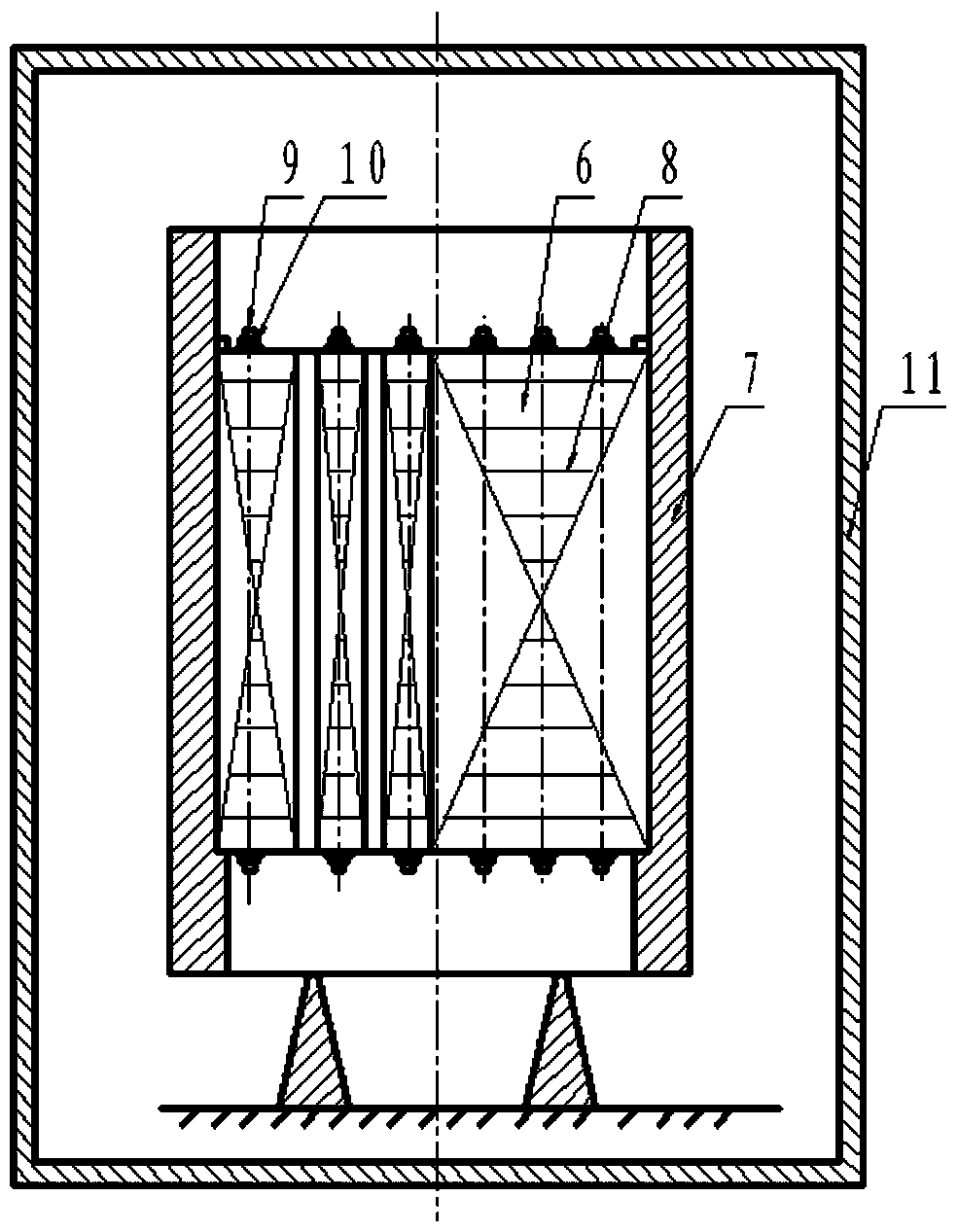

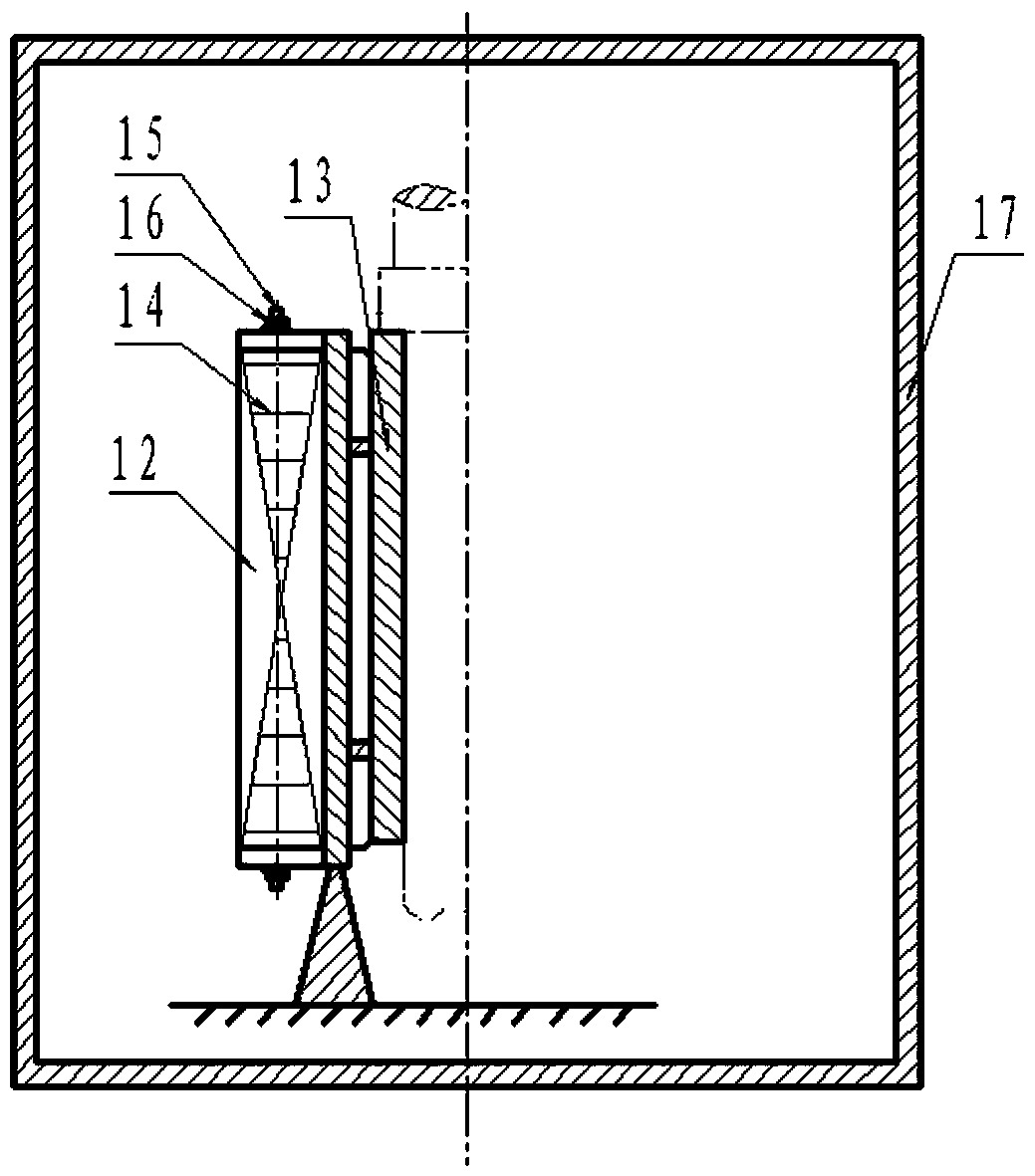

A compound methanol evaporator

ActiveCN113521773BReduce evaporation efficiencyGuaranteed buffer timeEvaporator accessoriesChemical industryLiquid stateElectric machinery

The present invention involves the field of evaporator technology. Specifically, a composite methanol evapator, including the box, the inner wall of the box is set with a filter, a two -layer evaporation mechanism is set up above the filter.Uniformly distributed, the inner wall of the box is set with multiple groups of round tubes, and the two ends of the multiple groups of round tubes are fixed with the sides of the inner wall of the box. There are multiple sets of atomized nozzles below the round tube.The end wall of the input liquid is connected to the inner wall of the round tube. The left side of the round tube runs through the inner wall of the box and extends to the outer fixing connection of the T -shaped tube.Users can use the liquid pump to spray liquid methanol through the atomized noble spray head on the evaporation mechanism. The motor will drive the evaporation mechanism to rotate the temperature in the process of using the use process, so as to avoid the spray of liquid methanol in the evaporation mechanism.Temperature cannot recover in time and reduce the evaporation efficiency of methanol.

Owner:浙江嘉诚动能科技股份有限公司

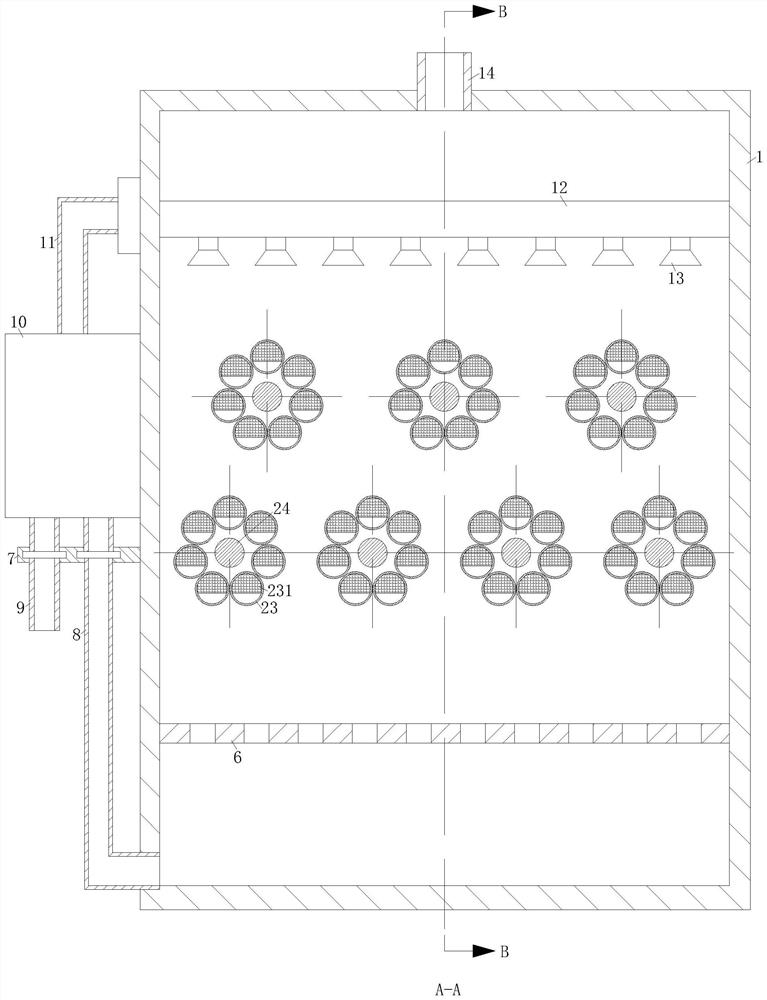

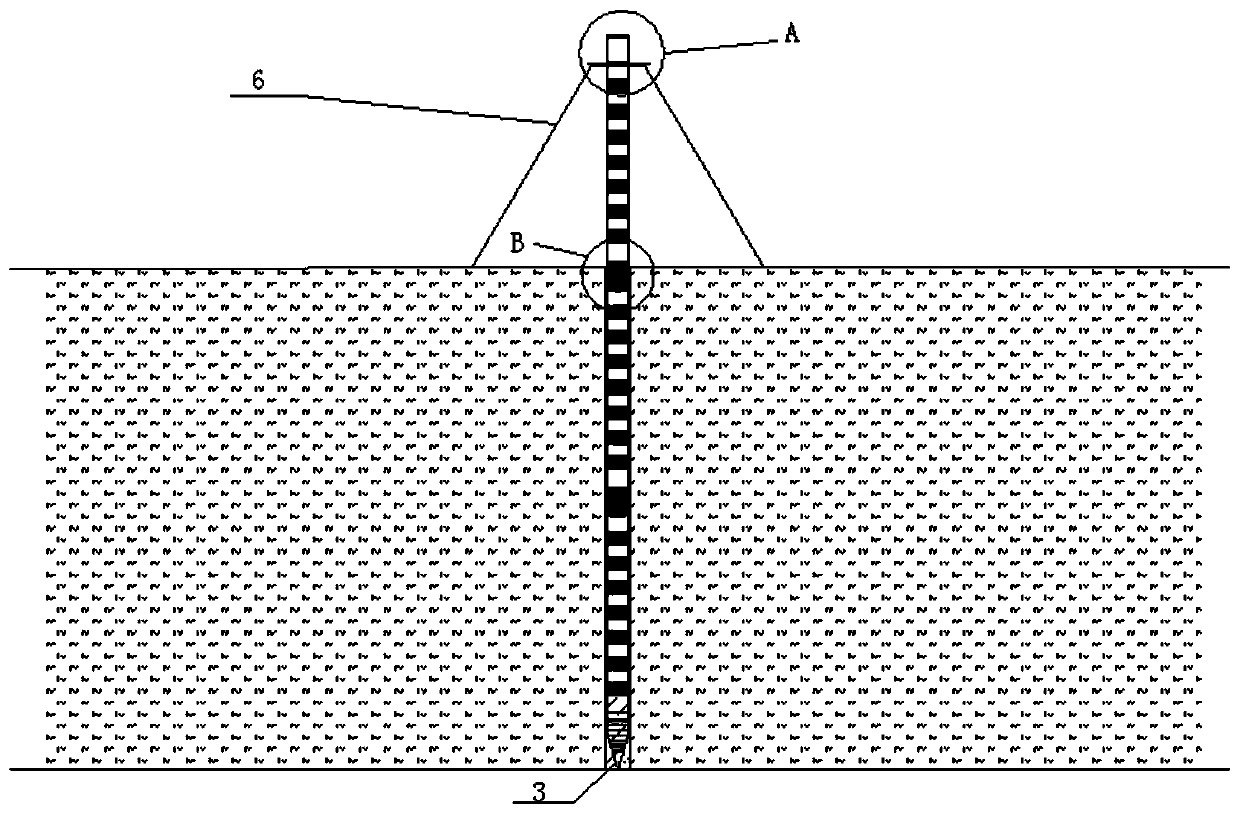

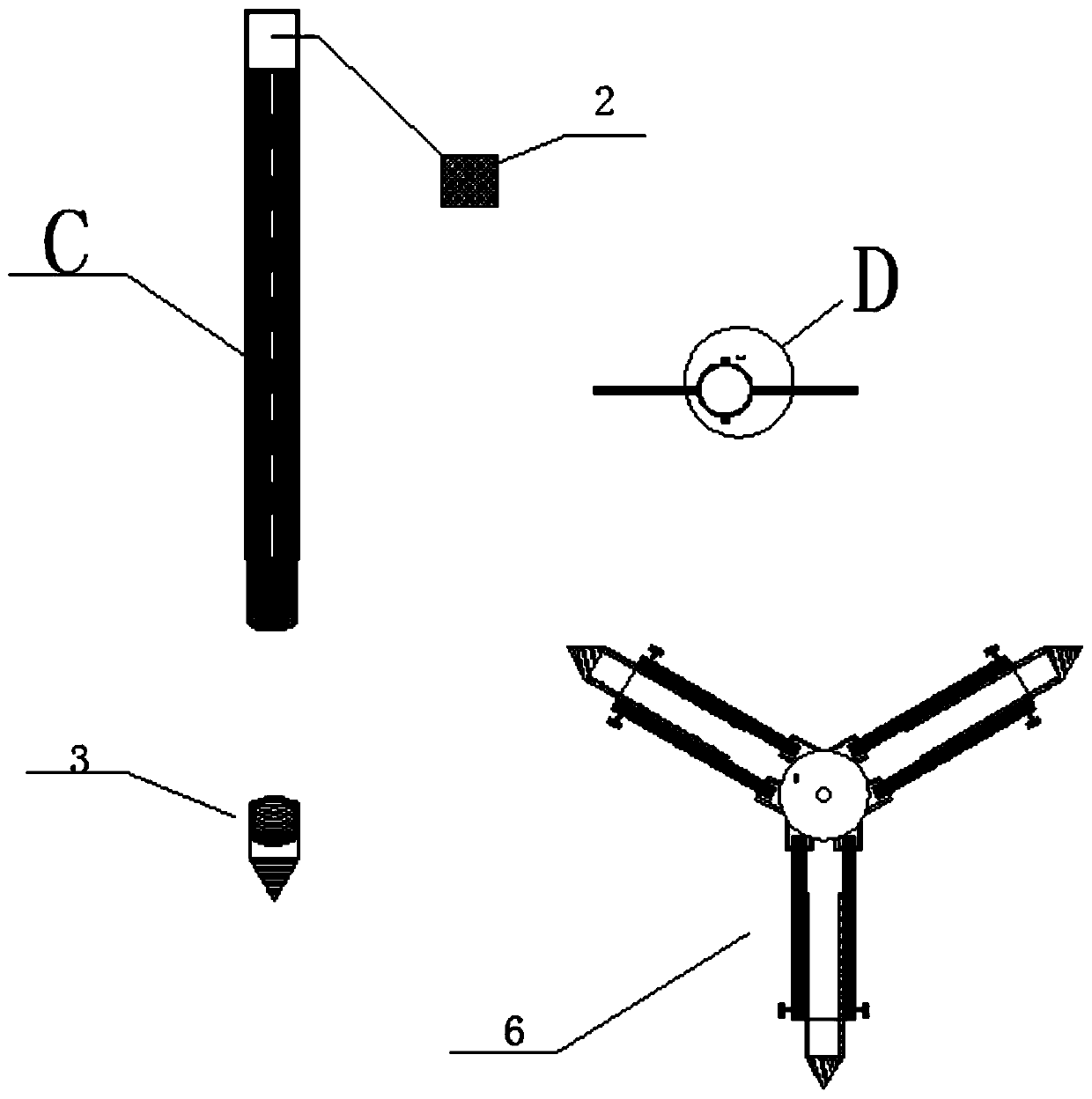

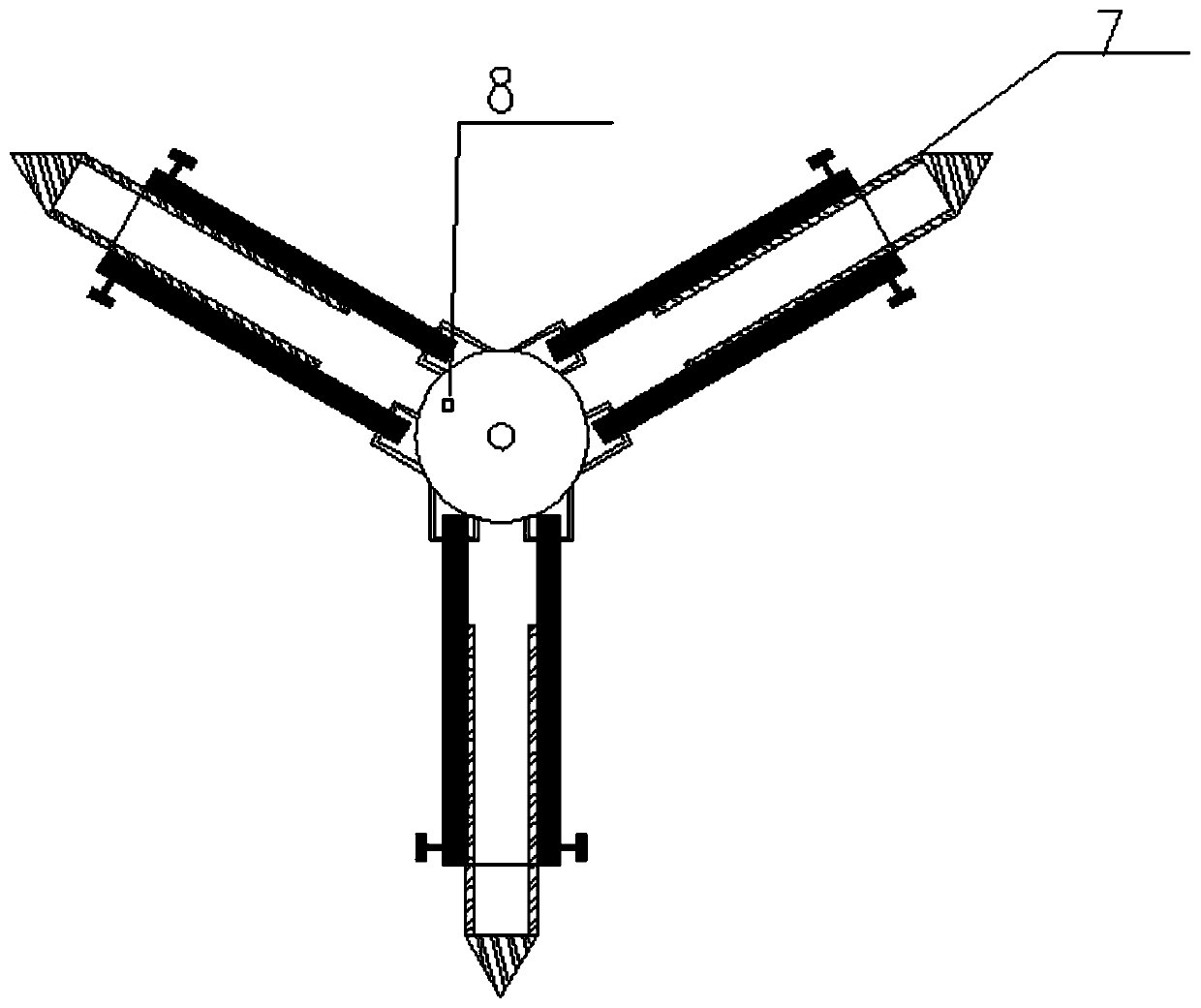

Drilled hole sealing device

The invention provides a drilled hole sealing device. The drilled hole sealing device comprises a prefabricated hole sealing pipe, a hole sealing material bag, a conical penetration head, hoop pipe-lowering equipment, a split bolt and an adjustable leveling and centering tripod, the prefabricated hole sealing pipe is made of wood, an inner thread is arranged on the upper part of the prefabricatedhole sealing pipe, the middle of the prefabricated hole sealing pipe is hollow, the outer wall of the prefabricated hole sealing pipe is in a grid shape, an outer thread is arranged on the lower partof the prefabricated hole sealing pipe, the prefabricated hole sealing pipe is filled with the hole sealing material bag, the conical penetration head and the prefabricated hole sealing pipe are detachably connected, the hoop pipe-lowering equipment is located on the upper part of the prefabricated hole sealing pipe and matched with the split bolt to fix the prefabricated hole sealing pipe, and the adjustable leveling and centering tripod is located on the lower part of the hoop pipe-lowering equipment. A drilled hole can be effectively plugged through the drilled hole sealing device, energy saving and environmental friendliness are achieved, multiple times of grouting is avoided, and the production cost is lowered.

Owner:WUXI MUNICIPAL DESIGN INST

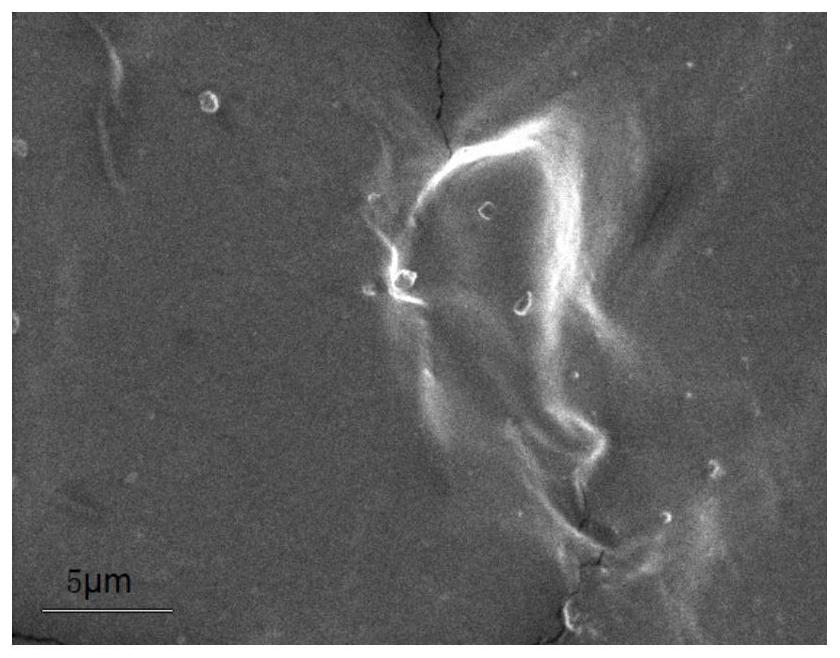

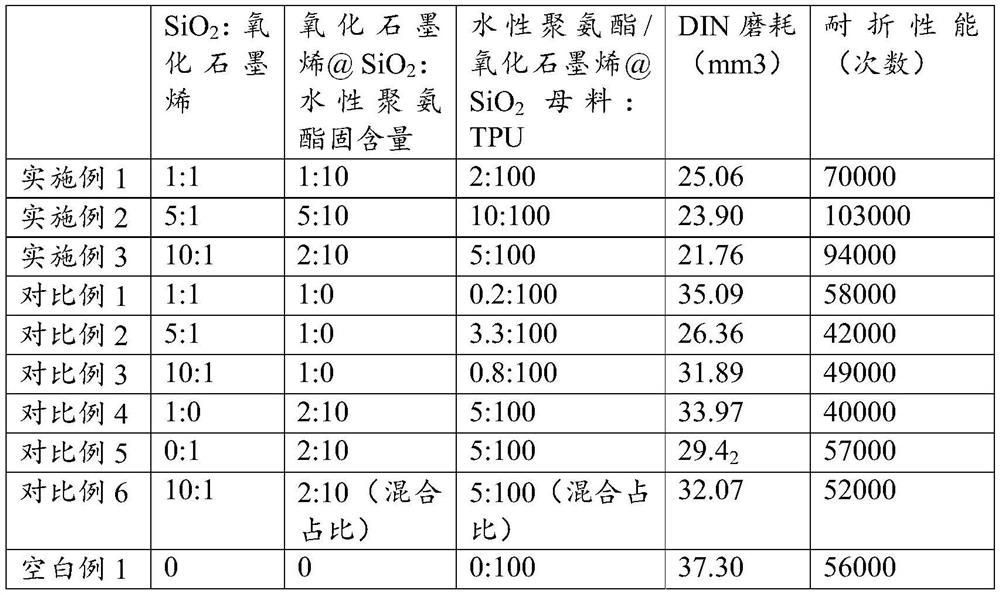

Polyurethane elastomer composite material, preparation method and application

PendingCN114539763AImprove wear resistanceImprove folding resistanceSolesBulk chemical productionFirming agentPolyurethane elastomer

The invention provides a polyurethane elastomer composite material preparation method, which comprises: S1, preparing 1-10 wt% of a nanometer SiO2 solution and 0.5-5 wt% of a graphene oxide slurry, adding the SiO2 solution into the graphene oxide slurry, and carrying out ultrasonic dispersion to obtain a graphene oxide / SiO2 solution; s2, stirring the graphene oxide / SiO2 solution at the temperature of 50-50 DEG C to evaporate the aqueous solution until the aqueous solution is pasty, and performing freeze drying at the temperature of-50 to-10 DEG C for 6-48 hours to obtain graphene oxide coated SiO2 aerogel; s3, adding the graphene oxide coated SiO2 aerogel into waterborne polyurethane, dispersing for 20-40 minutes by using a dispersing machine, dropwise adding a curing agent, dispersing for 5-15 minutes, curing for 1-3 hours in an incubator at 50-50 DEG C, taking out, embrittling for 10-20 minutes in liquid nitrogen, and crushing in a crusher to obtain a waterborne polyurethane / graphene oxide coated SiO2 master batch; and S4, physically mixing the waterborne polyurethane / graphene oxide coated SiO2 master batch and a polyurethane elastomer, carrying out electrostatic adsorption, and carrying out injection molding at 160-200 DEG C to obtain the polyurethane elastomer composite material. The material has high wear resistance and high folding resistance.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

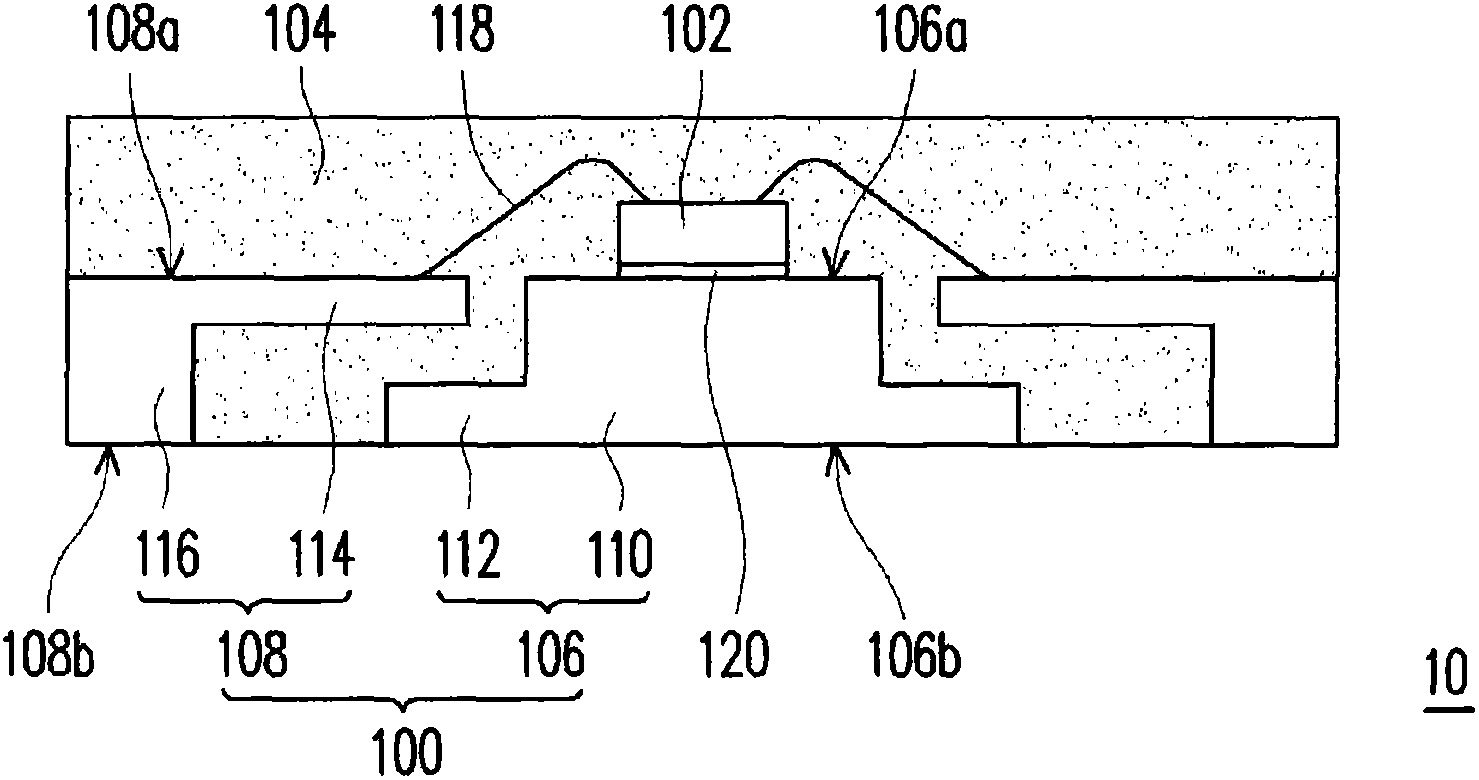

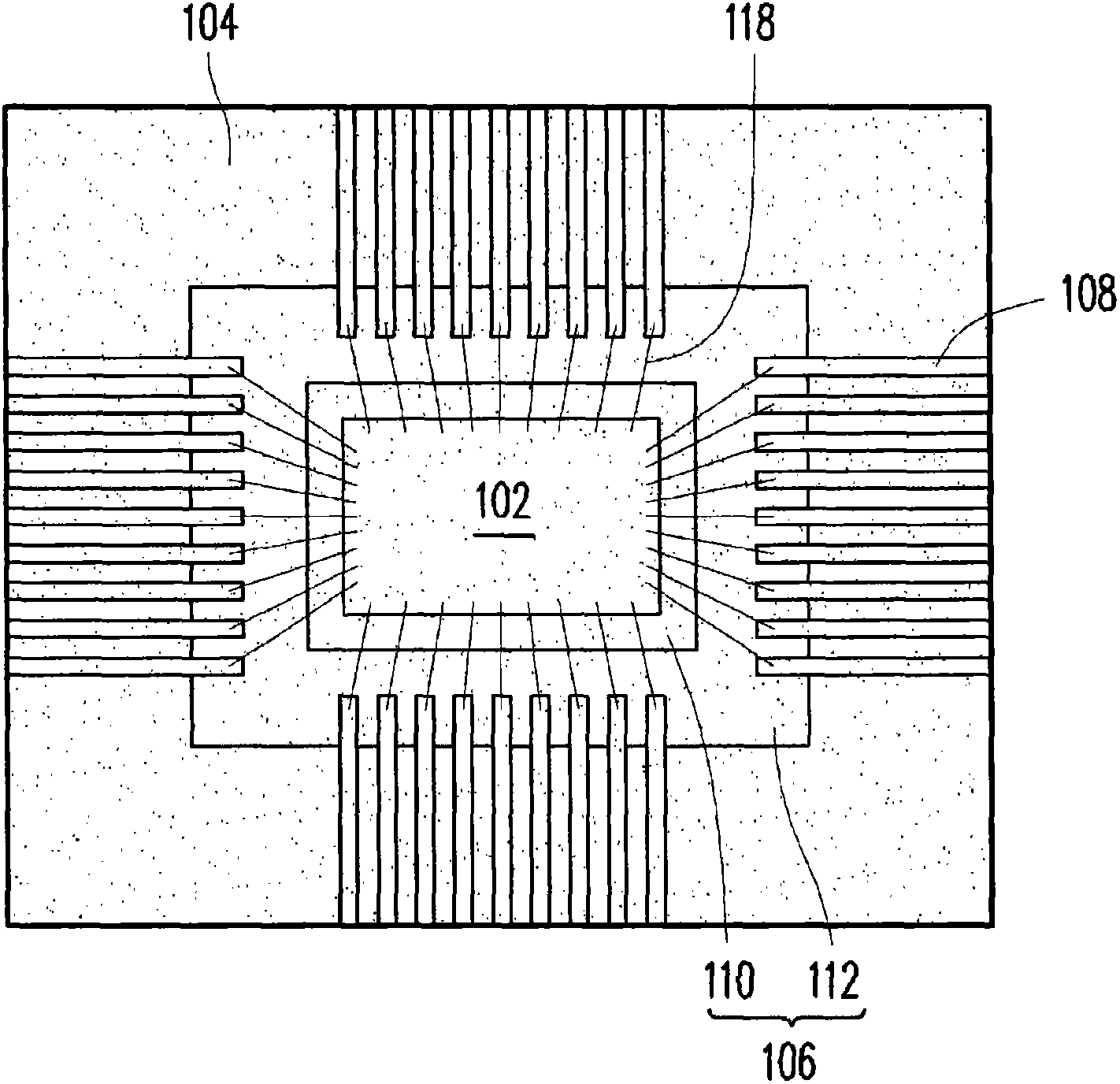

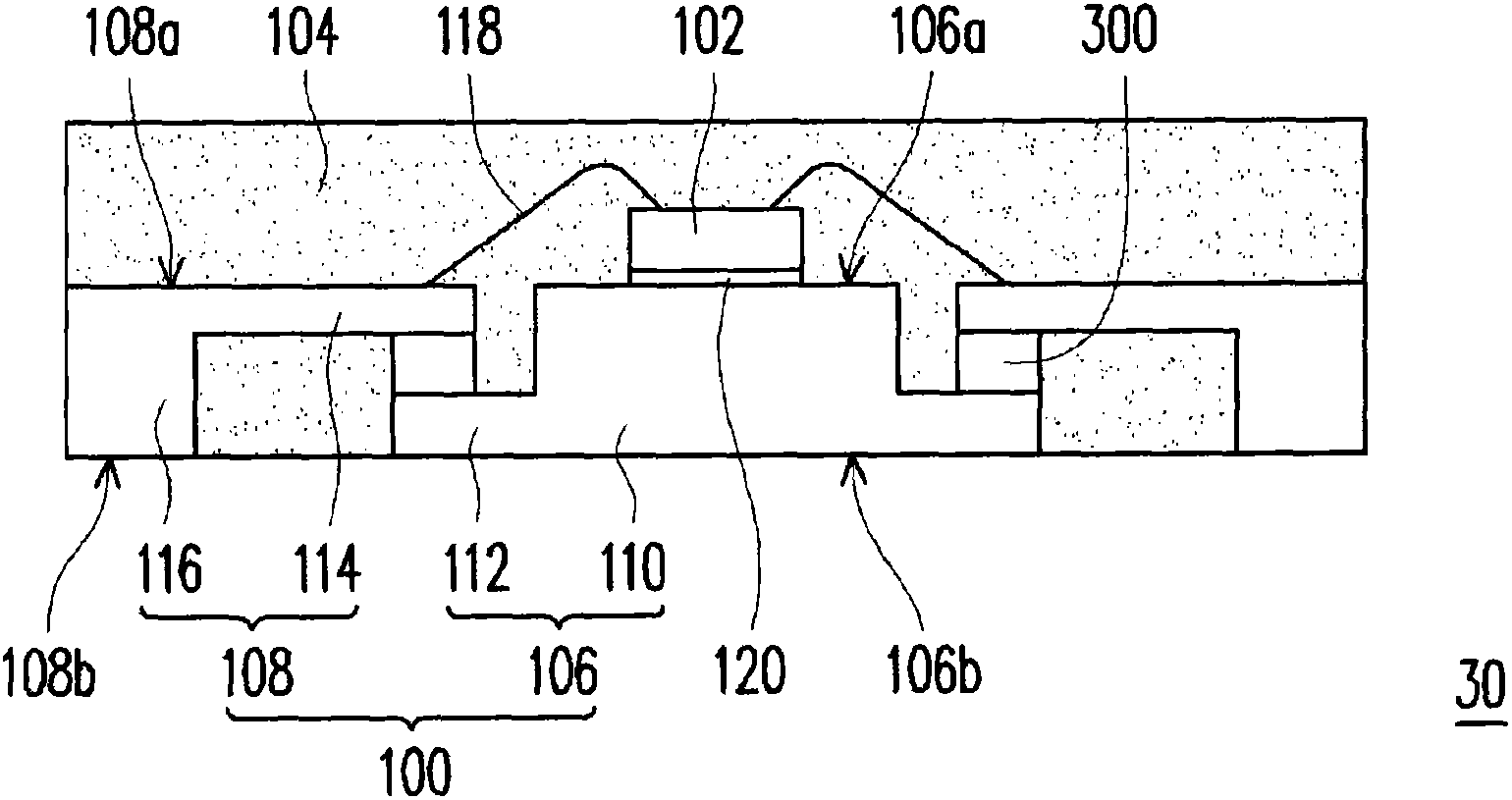

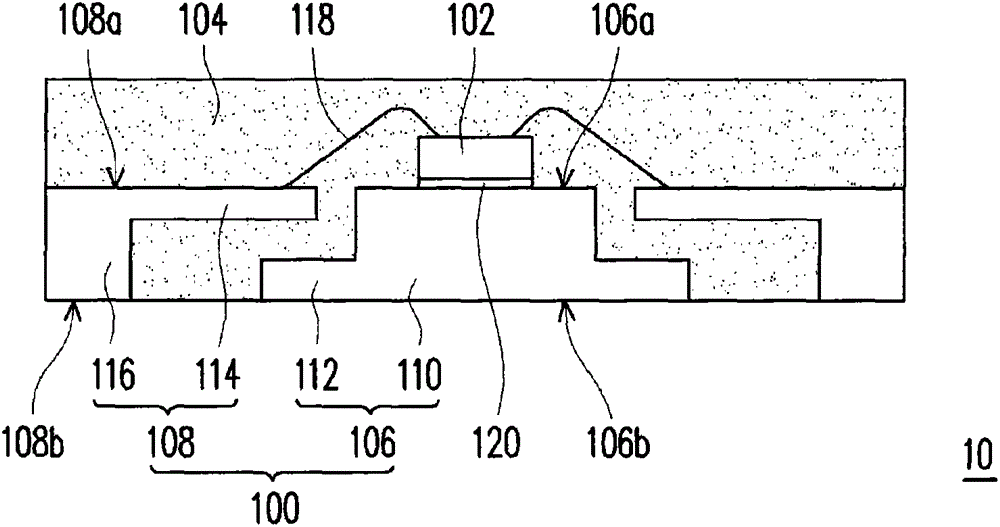

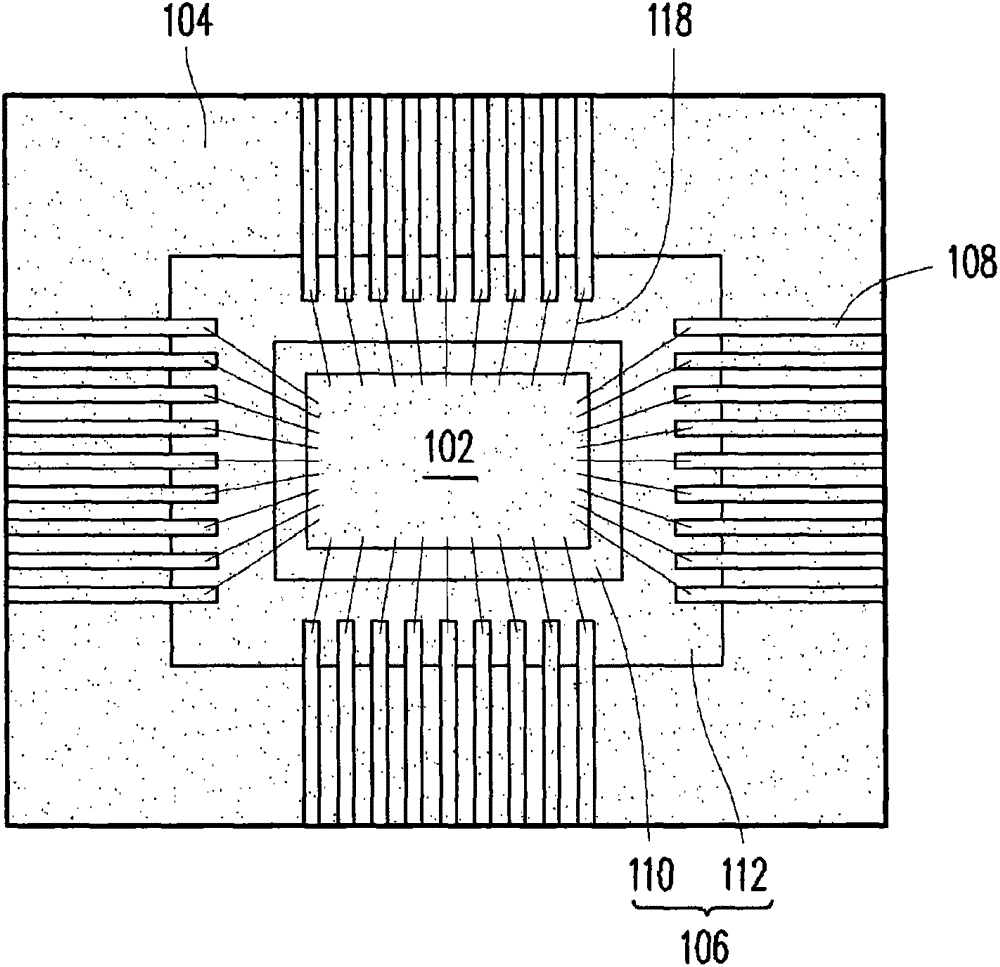

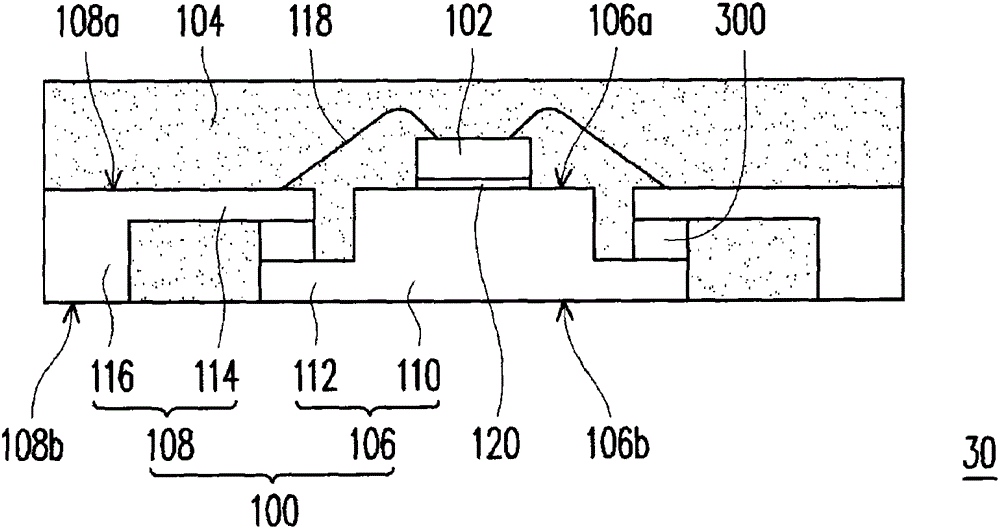

Packaging structure without external pin

ActiveCN102931150AShorten the lengthAvoid reduction in electrical performanceSemiconductor/solid-state device detailsSolid-state devicesColloidEngineering

A packaging structure without external pins comprises a wire rack, a chip, and a packaging colloid. The wire rack comprises a chip seat and a plurality of pins. The pin seat has a top surface and a bottom surface, and the chip seat comprises a chip jointing portion and a periphery portion. The periphery portion connects and encircles the chip jointing portion. The top surface of the chip seat outside the chip jointing portion is depressed to form the periphery portion. The pins are configured around the chip seat and are electrically separated from the chip seat. Each pin has a top surface and a bottom surface, and each pin comprises a cantilever portion and an external connection portion. Bottom surface of the pins outside the external connection portion are depressed to form the cantilever portions. The cantilever portion extends above the periphery portion from the external connection portion and partially overlaps with the periphery portion. The chip is configured on the chip jointing portion and electrically connected to the cantilever portion through a plurality of bonding wires. And the packaging colloid covers the chip, the bonding wires, and the wire rack.

Owner:CHIPMOS TECH INC

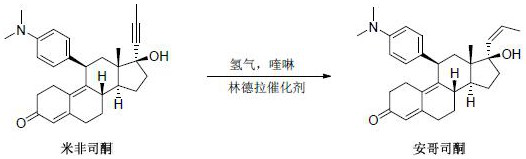

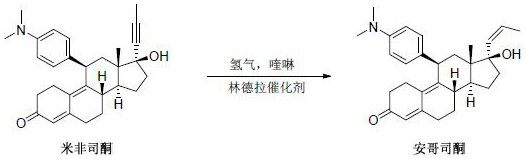

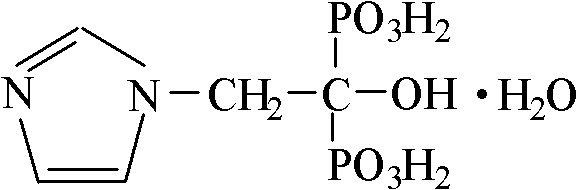

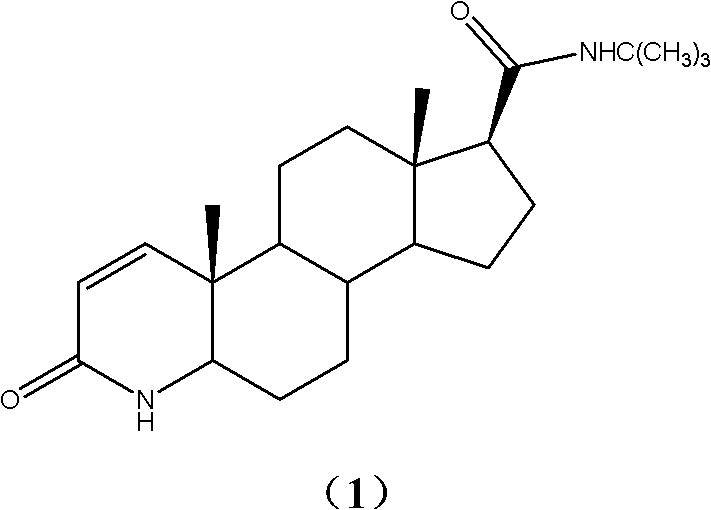

Synthesis method of ancopristone

PendingCN114195854AAvoid lowering production costsResponse Scale UpSteroidsChemistryLindlar catalyst

The invention relates to a synthesis method of ancopristone, which comprises the following steps: uniformly mixing mifepristone as a reaction substrate, a lindla catalyst, quinoline and an organic solvent, introducing hydrogen, and reacting in a hydrogen atmosphere; the reaction temperature is-20 DEG C to 50 DEG C, and the reaction time is 1-24 hours; and after the reaction is finished, filtering and concentrating to obtain the ancopristone.

Owner:ZHEJIANG XIANJU JUNYE PHARM CO LTD +1

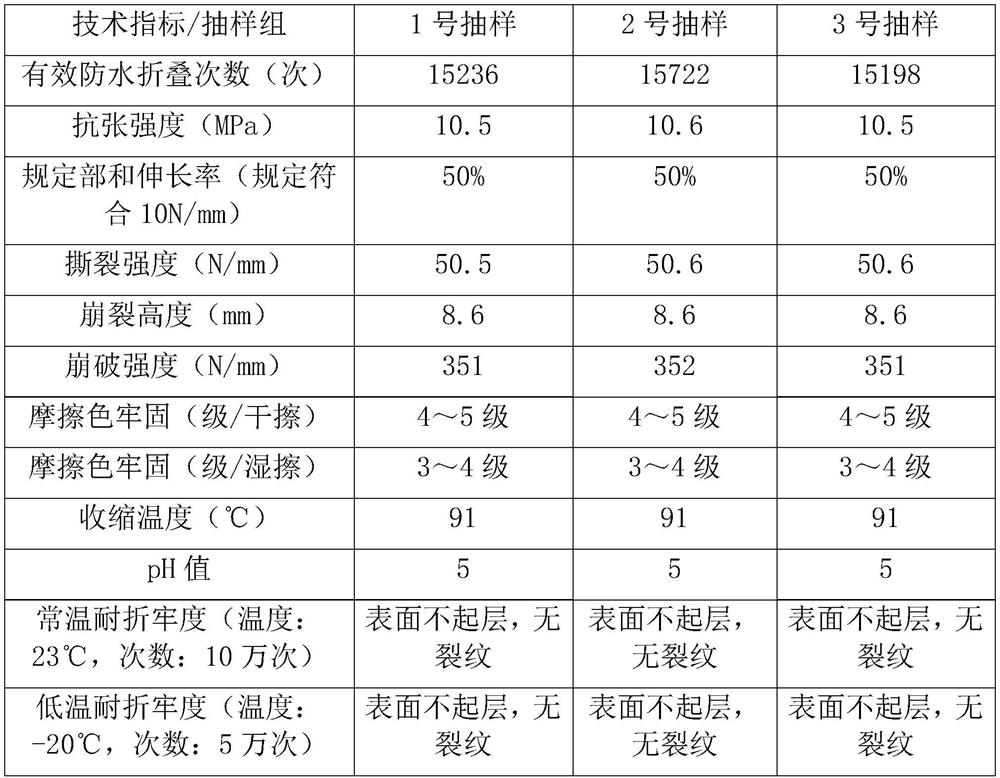

Manufacturing process of waterproof crazy horse leather

InactiveCN113695211AImprove waterproof performanceWon't breakPretreated surfacesCoatingsFiberAdhesive

The invention discloses a manufacturing process of waterproof crazy horse leather, and relates to the technical field of leather surface treatment. The process comprises the steps of material preparation, surface smoothing treatment, wet-process material treatment, wet-process base production, attachment and post-treatment to obtain the crazy horse leather, wherein a wet-process material comprises 30D polyurethane, 35D polyurethane, a DMF (dimethyl formamide) solvent and wood fiber powder, a produced wet-process material base uses guide cloth as a carrier, and the wet-process material base is stripped from the guide cloth and then bonded to cow split leather through a water-based adhesive. According to the process, the prepared wet-process base layer is attached to the waterproof split leather in a mold transfer manner, the damage to a waterproof layer on the leather surface caused by direct high-temperature coating is avoided, the number of bending times in effective waterproof use of the crazy horse leather is guaranteed, and compared with a traditional method, the number of bending times is increased by nearly one time and reaches 15000. Besides, the cow split leather can be used as a raw material for production, so that compared with a traditional method of using cow top grain leather, the production cost is greatly reduced, and the problem of raw material shortage in the industry is solved.

Owner:晋江国泰皮革有限公司

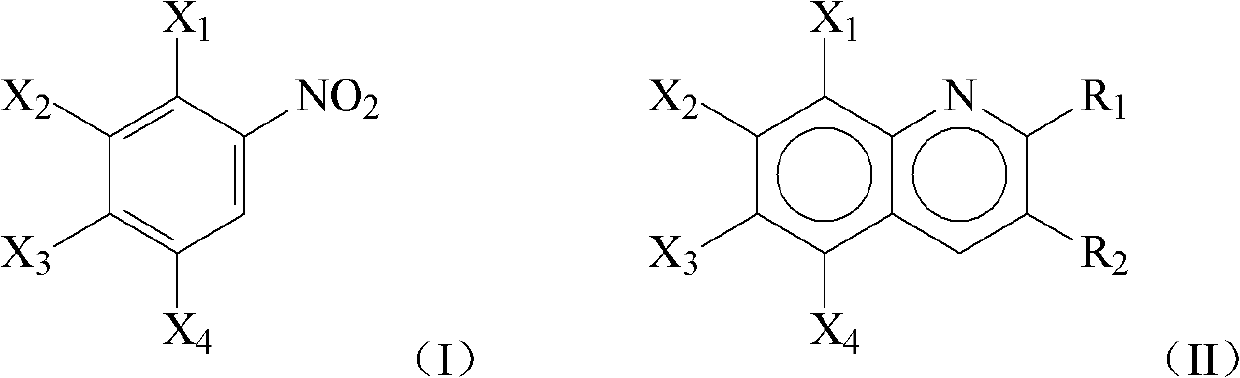

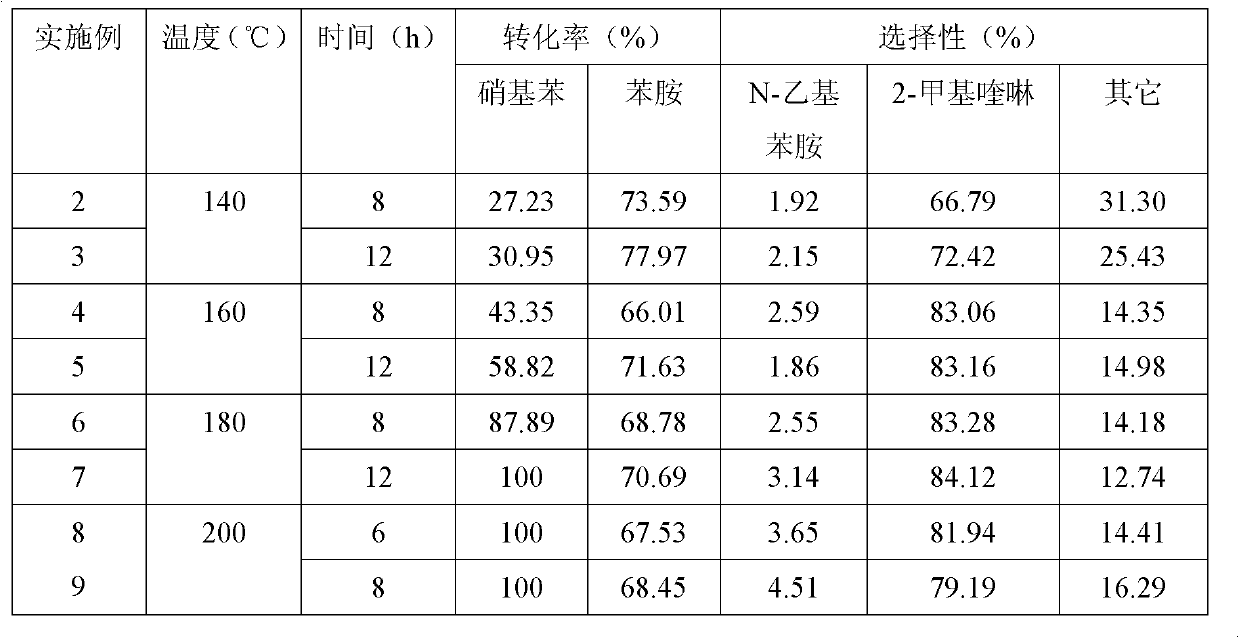

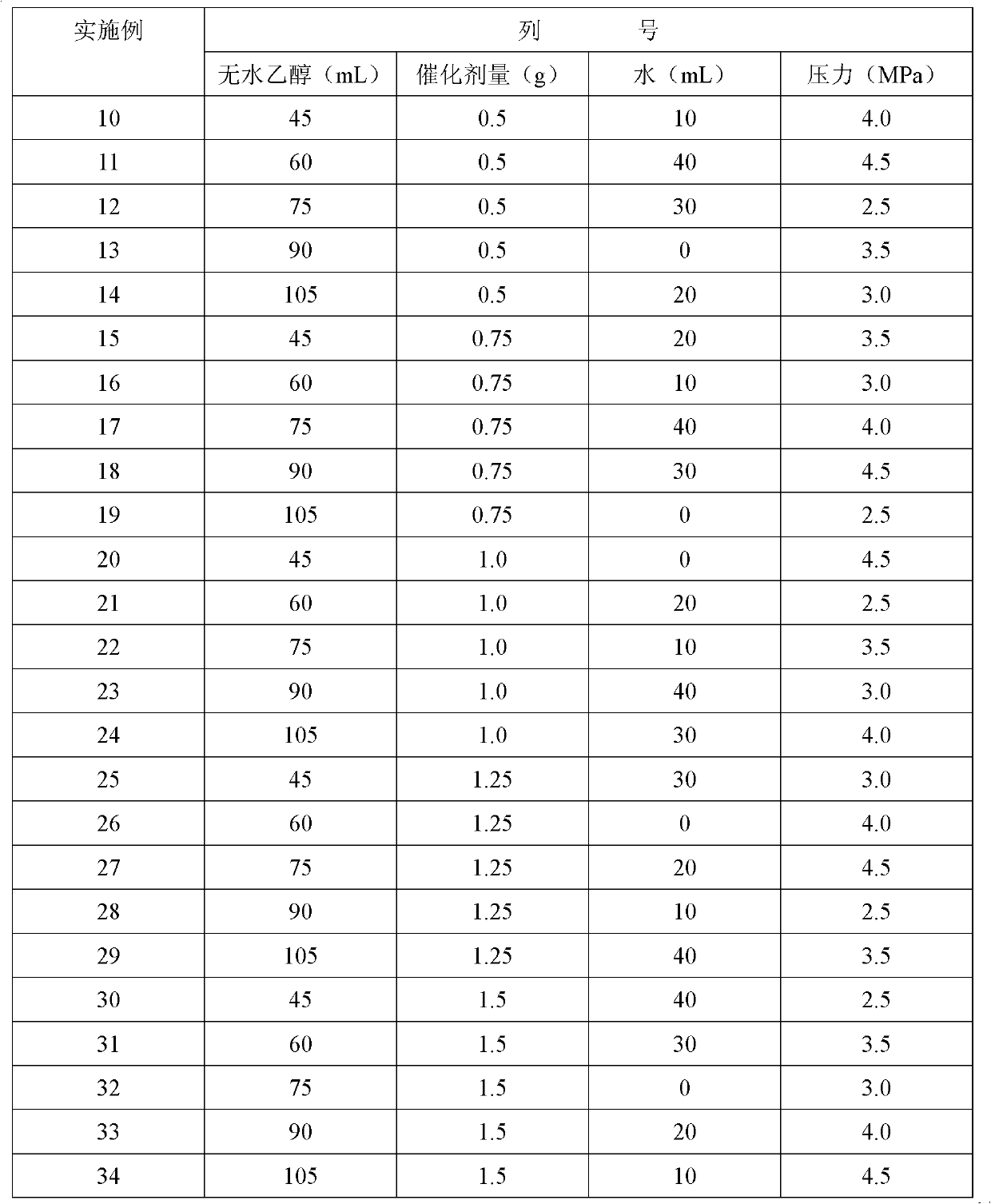

Method for one-pot liquid phase synthesis of quinoline and derivative thereof

The invention discloses a method for one-pot liquid phase synthesis of quinoline with formula (II) and derivative thereof. The method takes aromatic nitro-compound with formula (I) and fatty alcohol as the materials to react under the action of activator to prepare the quinoline or the derivative thereof, wherein the fatty alcohol is one of the C2-C5 fatty alcohols or the mixture of methanol and one of the C2-C5 fatty alcohols; and the activator is alumina supported palladium-copper solid activator. Through the method, the activator is easy to separate with the product and can be used repeatedly; the activator is easy to prepare and the noble metals are easy to recover, thus reducing the production cost; meanwhile, the product has good quality and high yield.

Owner:ZHEJIANG UNIV OF TECH

Zoledronic acid composition for injection and preparation method thereof

ActiveCN102000035BImprove uniformityInhibition releasePowder deliveryOrganic active ingredientsActivated carbonFreeze-drying

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

A kind of high specific gravity tungsten alloy material and preparation method thereof

Owner:HARBIN INST OF TECH +1

Esomeprazole sodium composition used for injection and its preparation method

ActiveCN102440965BInhibition releaseAvoid hidden dangersOrganic active ingredientsPowder deliveryActivated carbonAcetic acid

The invention provides an Esomeprazole sodium composition used for injection and its preparation method, the Esomeprazole sodium composition is prepared by the following steps: 1) liquid preparation: selecting esomeprazole sodium and ethylenediamine tetraacetic acid or ethylenediamine tetraacetic acid salt as raw materials, wherein the weight ratio of esomeprazole sodium to ethylenediamine tetraacetic acid or ethylenediamine tetraacetic acid salt is 1:0.01-0.1, weighting a proper amount of raw materials into a preparation tank, and adding water for injection to the weight of 23.47-234.7 timesof esomeprazole sodium, stirring and uniformly mixing the solution, adjusting the pH value of 10.0-12.5; 2) activated carbon finishing; 3) adsorbing; 4) sterile filtrating and split charging; 5) vacuum freeze-drying to obtain the esomeprazole sodium composition used for injection. The esomeprazole sodium composition used for injection and the preparation method are capable of ensuring the heat source, visible foreign matter and insoluble particulate to accord with the requirements of the injection for the injection preparations such as esomeprazole sodium preparation liquid with high pH value.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

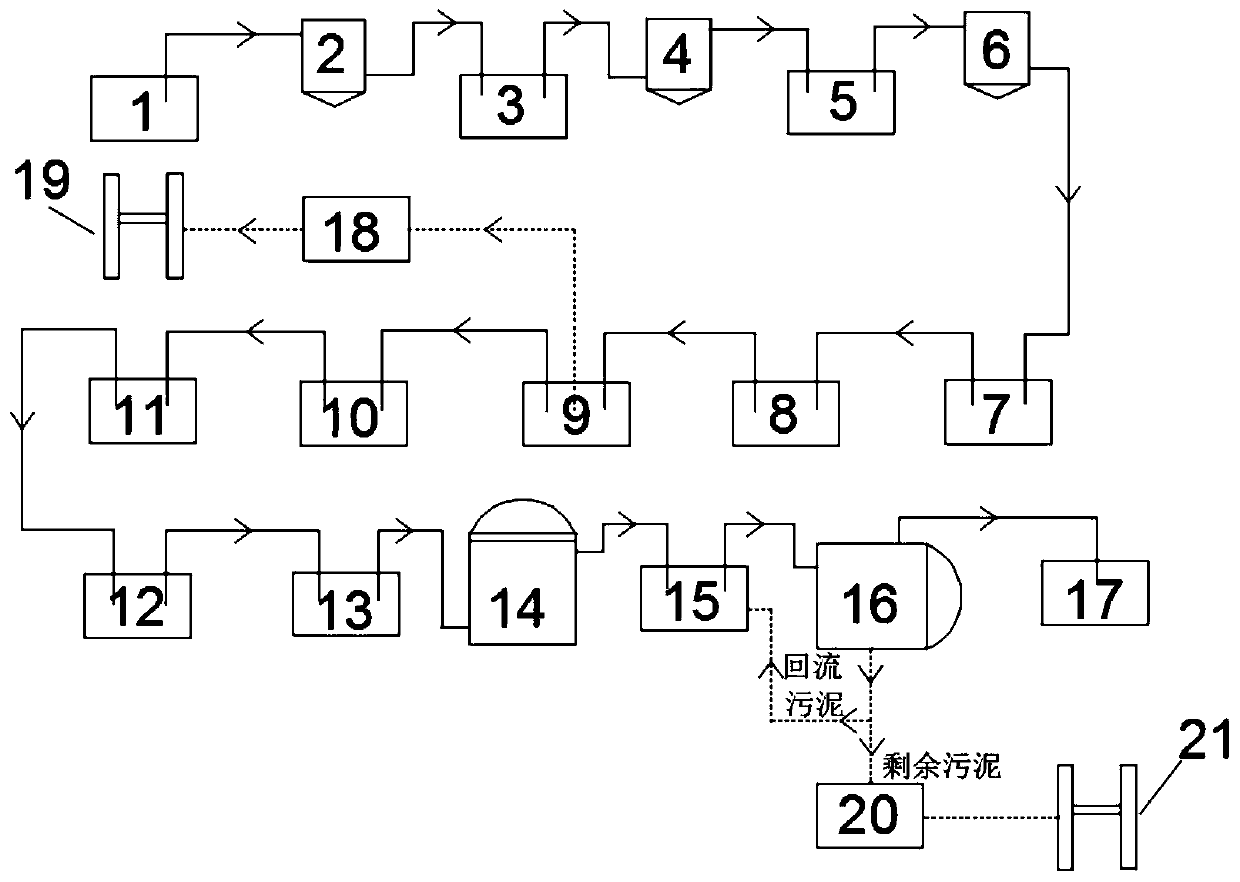

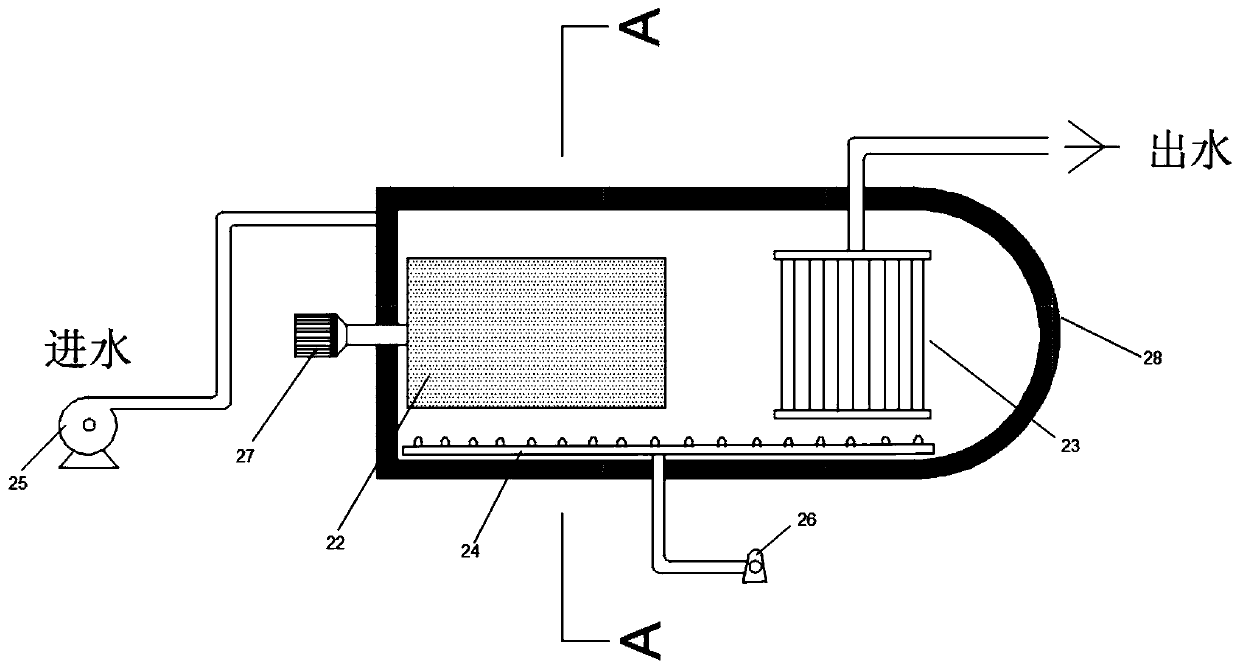

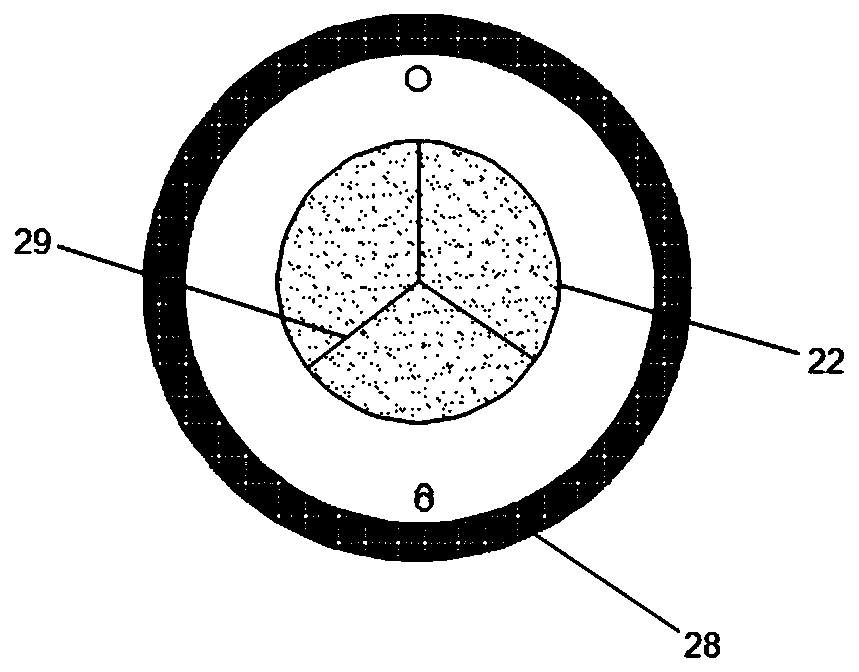

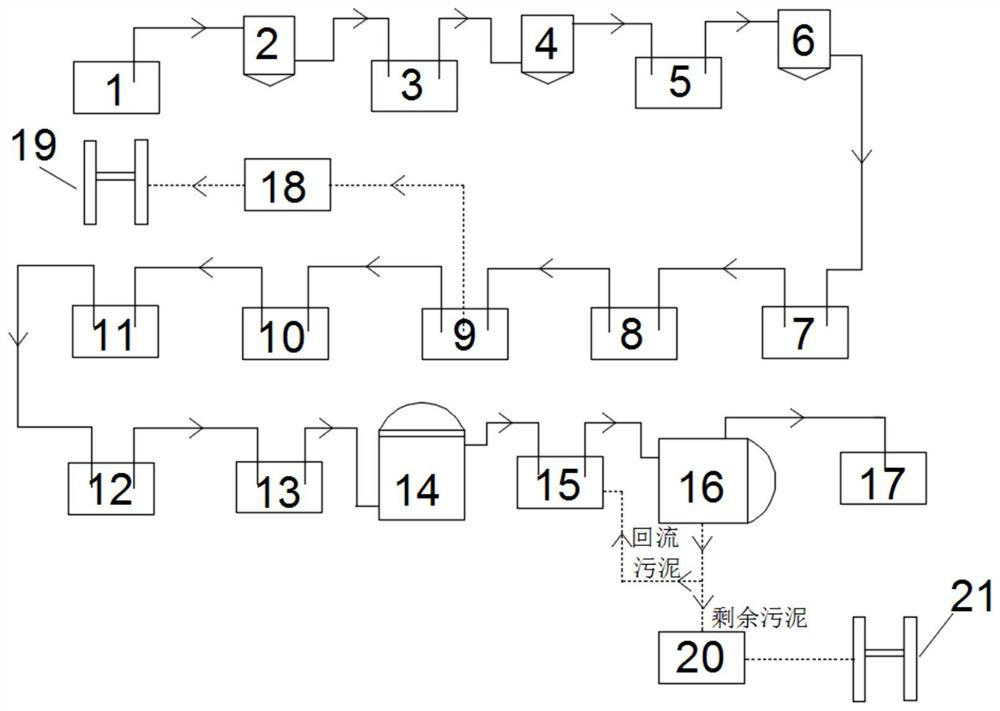

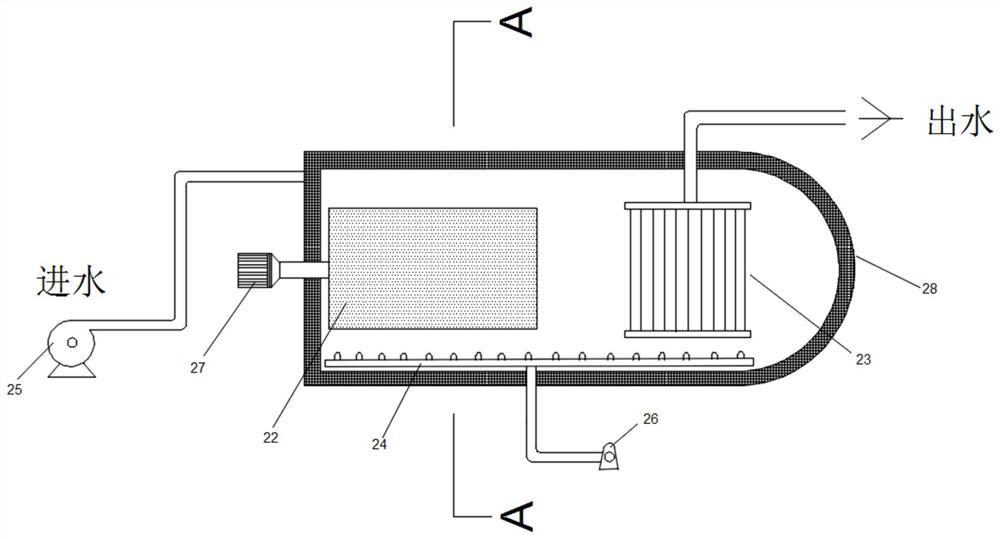

Sewage treatment system

ActiveCN111003900AImprove biodegradabilityEmission complianceFatty/oily/floating substances removal devicesTreatment by combined electrochemical biological processesElectrolysisWater treatment system

The invention discloses an efficient sewage treatment system, which can simultaneously solve the problems of easy hardening and passivation of a micro-electrolysis filler and membrane flux reducing caused by interception of pollutants by an MBR membrane assembly by coupling a micro-electrolysis treatment device and an MBR membrane bioreactor so as to completely achieve the synergistic effect of the micro-electrolysis treatment device and the MBR membrane bioreactor. According to the invention, an iron-carbon filler is placed in a rotor core divided into a plurality of chambers by partition plates, the rotor core rotates during sewage treatment, the iron-carbon filler rolls in the chamber along with the rotation of the rotor core while the iron-carbon filler is subjected to a micro-electrolysis reaction so as to effectively avoid the hardening and passivation of the filler, the rotation of the rotor core can stir the sewage flow in the coupling reactor, and the disturbed water flow forms scouring on the surface of the membrane, so that the membrane flux reducing caused by retention of pollutants on the surface of the membrane can be effectively avoided, the cleaning and replacing frequency of the membrane is greatly reduced, and the production cost is reduced while the sewage treatment effects of micro-electrolysis and membrane biological reaction are fully exerted.

Owner:四川环科美能环保科技有限公司

No external lead package structure

ActiveCN102931150BShorten the lengthAvoid reduction in electrical performanceSemiconductor/solid-state device detailsSolid-state devicesColloidCantilever

A packaging structure without external pins comprises a wire rack, a chip, and a packaging colloid. The wire rack comprises a chip seat and a plurality of pins. The pin seat has a top surface and a bottom surface, and the chip seat comprises a chip jointing portion and a periphery portion. The periphery portion connects and encircles the chip jointing portion. The top surface of the chip seat outside the chip jointing portion is depressed to form the periphery portion. The pins are configured around the chip seat and are electrically separated from the chip seat. Each pin has a top surface and a bottom surface, and each pin comprises a cantilever portion and an external connection portion. Bottom surface of the pins outside the external connection portion are depressed to form the cantilever portions. The cantilever portion extends above the periphery portion from the external connection portion and partially overlaps with the periphery portion. The chip is configured on the chip jointing portion and electrically connected to the cantilever portion through a plurality of bonding wires. And the packaging colloid covers the chip, the bonding wires, and the wire rack.

Owner:CHIPMOS TECH INC

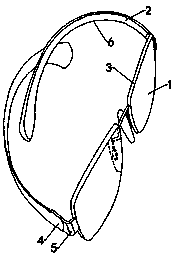

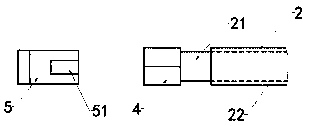

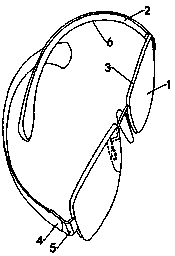

Convenient eyeglass structure

InactiveCN109839755AEasy to installReduce manufacturing costNon-optical partsEyeglass lensesEngineering

The invention relates to a convenient eyeglass structure, which comprises eyeglass bracket and eyeglass lenses (1), wherein the eyeglass frame includes eyeglass legs (2) and an eyeglass frame (3), theeyeglass lenses (1) are installed in the eyeglass frame (3), and the eyeglass legs (2) are connected with the eyeglass frame (3). The convenient eyeglass structure is characterized in that the eyeglass legs (2) are elastic eyeglass legs and composed of an elastic beam (21) and a packaging layer (22), the elastic beam (21) is provided with an insertion slot (4) at the end connected with the eyeglass frame (3), and the elastic beam (21) is wrapped in the packaging layer (22) except for the insertion slot (4); and two ends of the eyeglass frame (3) are respectively provided with connecting arms(5), the connecting arm (5) is provided with an elastic buckle (51), the eyeglass leg (2) is fixed on the eyeglass frame (3) through the cooperation of the insertion slot (4) and the elastic buckle (51). The eyeglass structure of the invention has the advantage of convenient and fast installation, thereby avoiding the use of screws, and reducing the production cost.

Owner:江苏恒畅光学眼镜有限公司

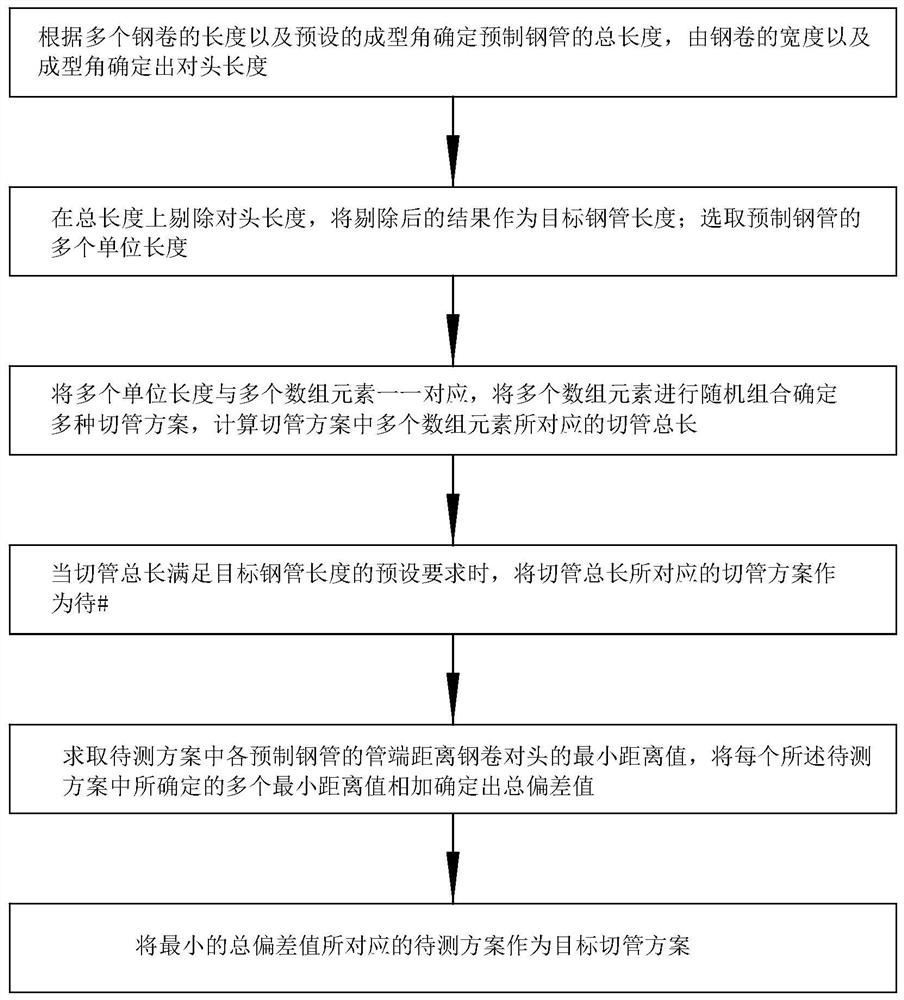

Combined pipe cutting method and system

ActiveCN111515449BReduce lossImprove product qualityTube shearing machinesShearing machine accessoriesPipeMechanical engineering

The invention provides a pipe cutting combination method and system, which belong to the technical field of steel pipe cutting. The pipe cutting combination method includes: removing the opposite length from the total length, and using the removed result as the target steel pipe length; combining multiple unit lengths with multiple arrays One-to-one correspondence of elements, multiple array elements are randomly combined to determine multiple pipe cutting schemes, and the total length of pipe cutting corresponding to multiple array elements in the pipe cutting scheme is calculated. Calculate the minimum distance value between the pipe end of each prefabricated steel pipe in the scheme to be tested and the opposite end of the steel coil, and add the multiple minimum distance values determined in each scheme to be tested to determine the total deviation value. The scheme to be tested corresponding to the smallest total deviation value is taken as the target pipe cutting scheme. The present application also provides a pipe cutting system. The pipe cutting combination method and system provided by the present invention can find the optimal pipe cutting scheme on the basis of determining the length of the steel coil and the position of the opposite end of the steel coil, which reduces the loss of the steel coil, improves the product quality of the steel coil, and reduces the production cost.

Owner:NORTH CHINA GASOLINEEUM STEEL PIPE

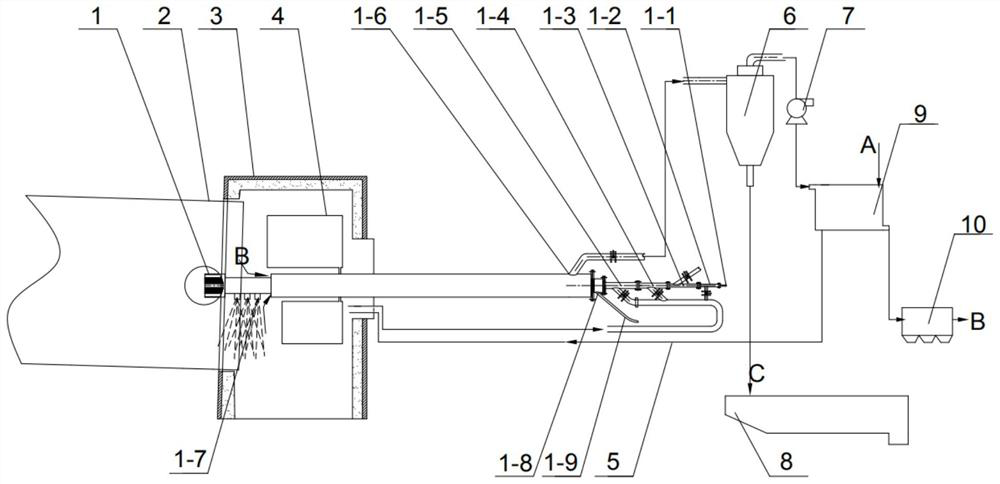

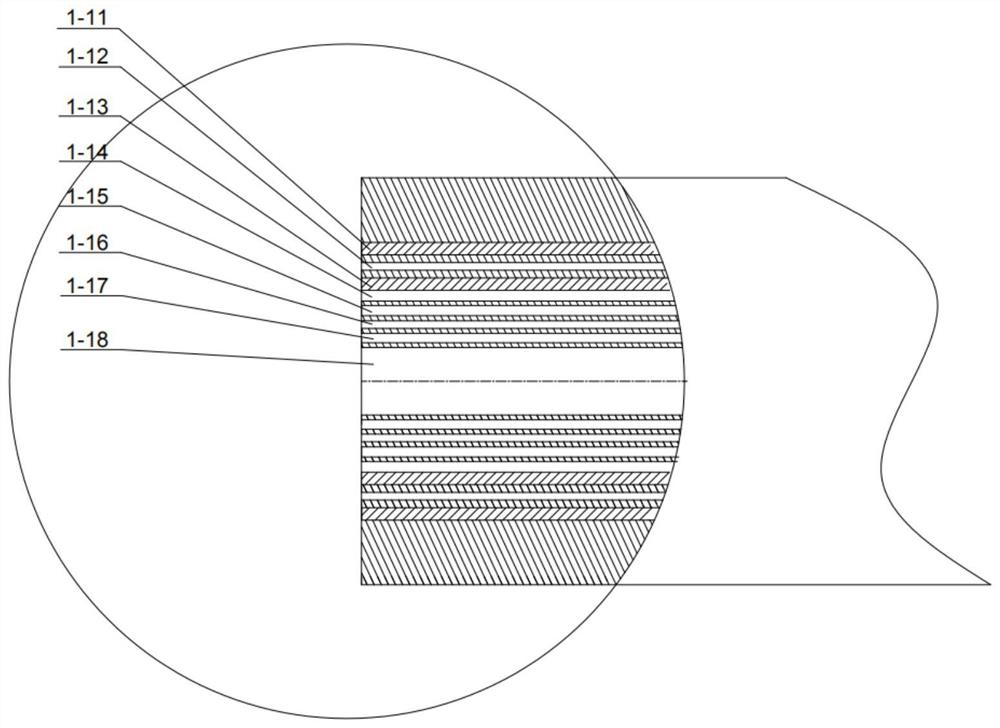

Combined white cement combustion bleaching system

PendingCN112723769ALower flame temperaturePrevent free calcium from exceeding the standardRotary drum furnacesIncreasing energy efficiencyCombustorDust control

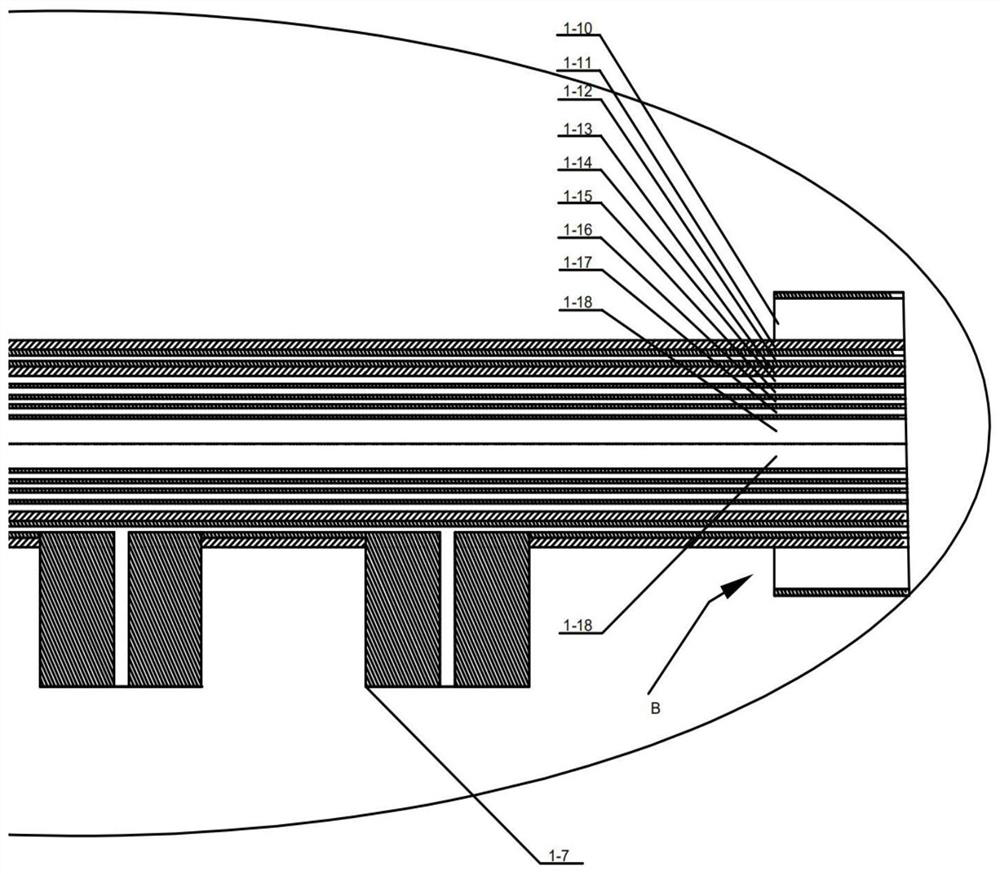

The invention relates to a combined white cement combustion bleaching system, which comprises a combustor (1), a high-temperature heat exchanger (4), a primary air pipe (5), a pre-dedusting device (6), a high-temperature fan (7), a grate cooler (8), a low-temperature heat exchanger (9) and a dust collector (10), wherein an ignition oil gun channel (1-18), a center air channel (1-17), a coal supply air channel (1-16), a rotational flow air channel (1-15), an axial flow air channel (1-14) and a cold water channel (1-12) are formed in the left end of the combustor (1) in the axial direction. According to the invention, hot steam can be prevented from flowing into the rotary kiln to reduce the temperature of flame in the kiln, so that free calcium in clinker is prevented from exceeding the standard so as to effectively guarantee the quality of the clinker; and the temperature difference between the primary air and the rotary kiln (2) is reduced, so that the flame temperature in the rotary kiln is further prevented from being reduced, and further the increase of firing heat consumption is effectively avoided so as to greatly reduce the production cost.

Owner:NANJING KISEN INT ENG

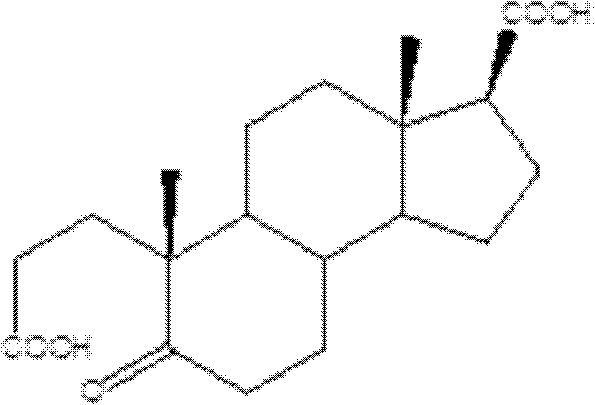

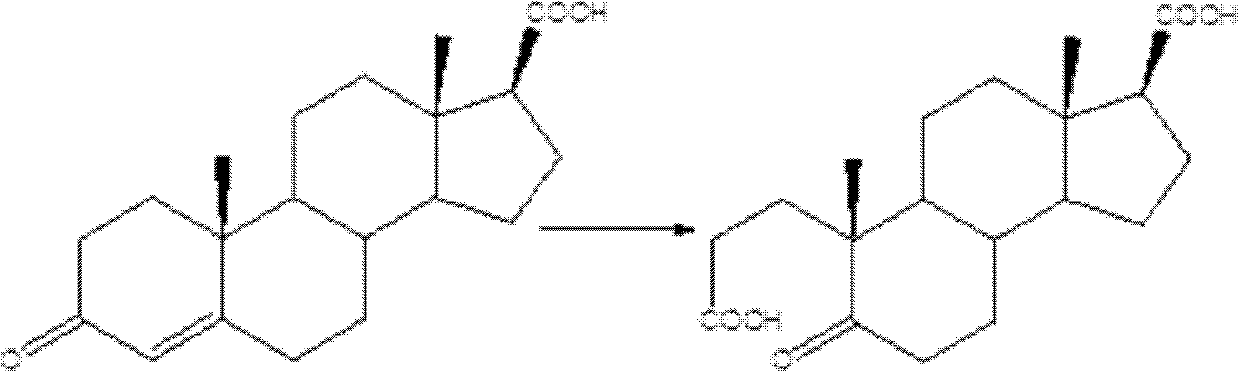

Synthetic method of A-nor-3,5-cracking-androstane-5-ketone-3,17 beta-diacid

Owner:HUNAN KEREY BIOTECH

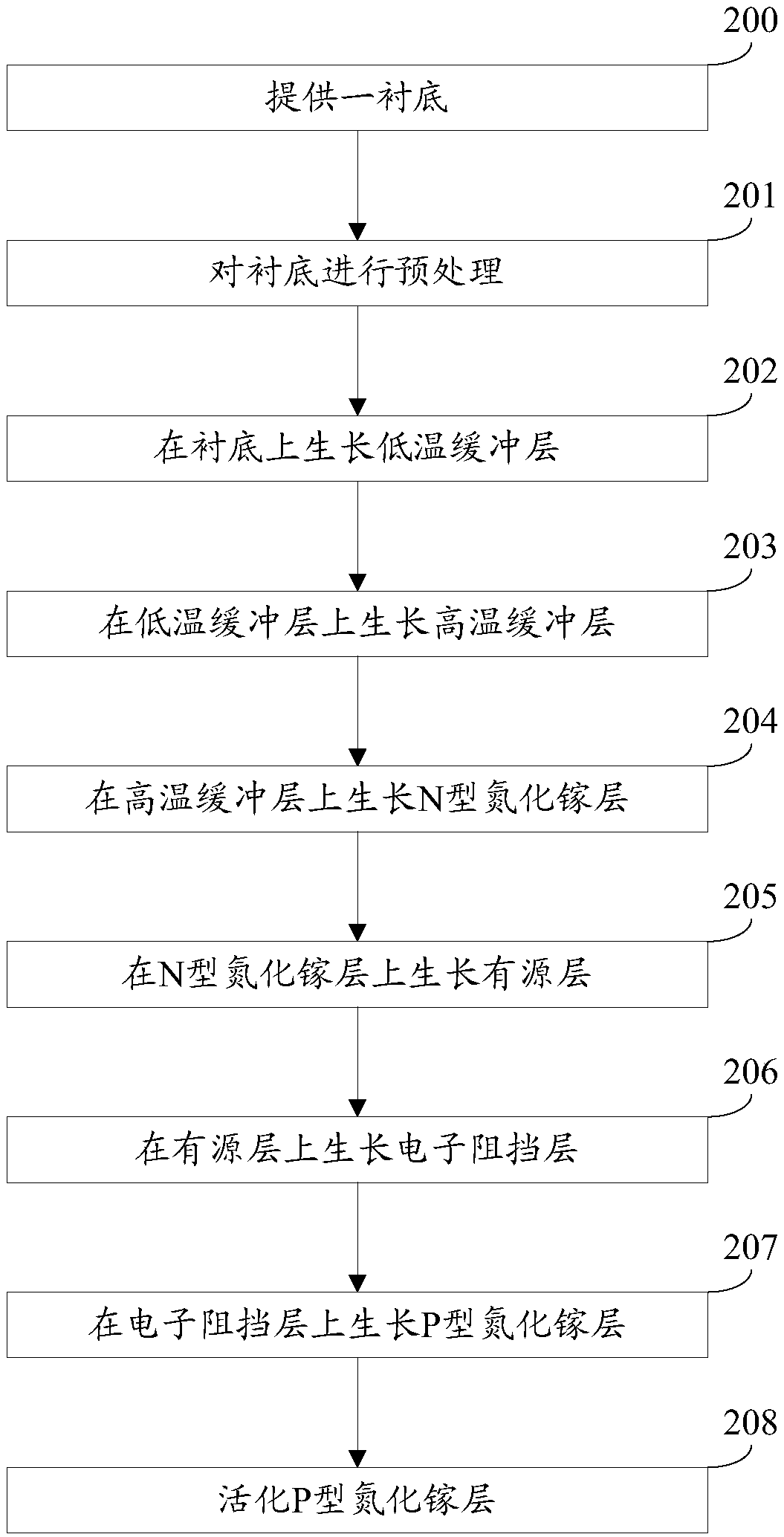

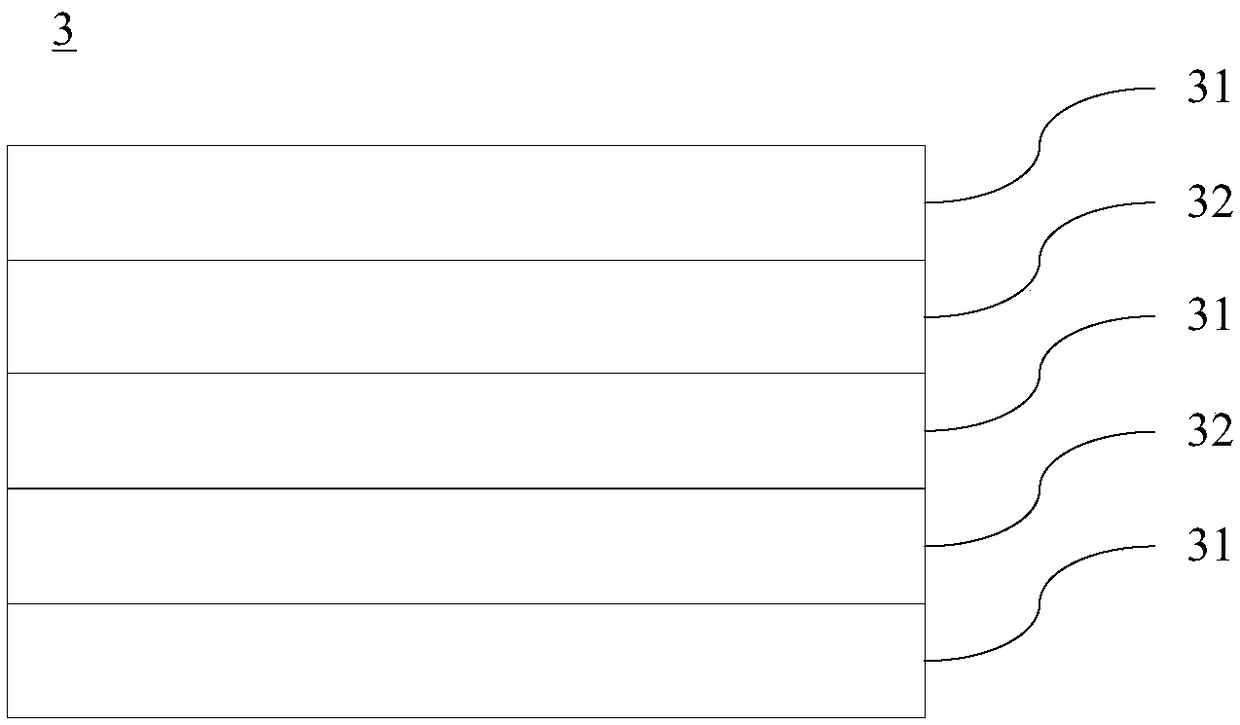

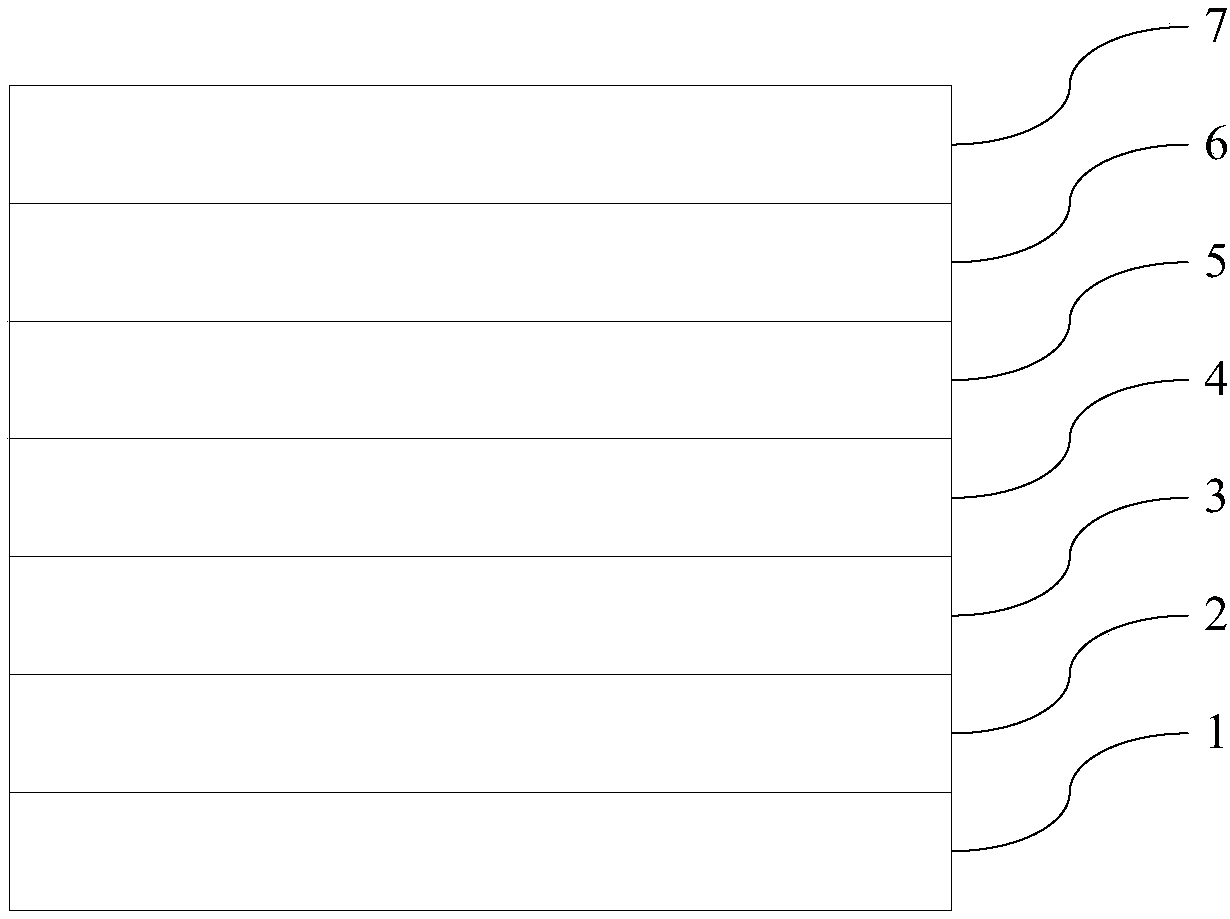

A method of manufacturing a light-emitting diode epitaxial wafer

ActiveCN107086256BAvoid lowering production costsAvoid Crystal Quality EffectsSemiconductor devicesGallium nitrideBlocking layer

Owner:HC SEMITEK ZHEJIANG CO LTD

a sewage treatment system

ActiveCN111003900BImprove biodegradabilityEmission complianceFatty/oily/floating substances removal devicesTreatment by combined electrochemical biological processesElectrolysisWater treatment system

The invention discloses a high-efficiency sewage treatment system, which can simultaneously solve the problems of easy hardening and passivation of micro-electrolysis fillers and reduction of membrane flux caused by pollutants intercepted by MBR membrane components through the coupling of micro-electrolysis treatment devices and MBR membrane bioreactors. , give full play to the synergistic effect of the two. The advantage of the present invention is that: the present invention places the iron-carbon filler in the rotor core divided into a plurality of compartments by the separator, and the rotor core rotates when the sewage is treated. The rotation of the core rolls in the chamber, which can effectively avoid the hardening and passivation of the filler. On the other hand, the rotation of the rotor core can stir the sewage water flow in the coupling reactor, and the disturbed water flow forms a scour on the surface of the membrane, which can effectively avoid pollution. The membrane flux is reduced due to the stagnation of substances on the membrane surface, which greatly reduces the frequency of membrane cleaning and replacement, and reduces the production cost while giving full play to the role of micro-electrolysis and membrane biological reaction in sewage treatment.

Owner:四川环科美能环保科技有限公司

Method for preparing sintered ores by adding chromite into low-chromium vanadium titano-magnetite

The invention relates to a method for preparing sintered ores by adding chromite into low-chromium vanadium titano-magnetite. The method is characterized in that the low-chromium vanadium titano-magnetite, the chromite and other sintered materials are subjected to the following steps of material mixing, material stewing, material mixing, material pelleting, material distribution, ignition, sintering, crushing and sieving to obtain the low-chromium vanadium-titanium sintered ores. According to the method, the problem that material mixing is not uniform is effectively avoided, air permeability and the sintering rate of the sintered materials in the sintering process are effectively improved, the problem that the sintering rate is reduced due to the fact that ball materials with relatively large particle sizes are not completely burnt is also avoided, production cost is effectively reduced, energy is saved, the sintering speed is further improved, and the yield is high; the sintered oresprepared by the method has good air permeability in a soft melting and dripping zone, the performance of the molten drops is good, the yield is high, the metallurgical performance is good, and compared with the prior art, the recovery rate of Fe and Cr is greatly improved; and the method has the advantages that a theoretical basis and a technical foundation are provided for reasonably utilizing the method for preparing the sintered ores by adding the chromite into the Hong Ge low-chromium vanadium titano-magnetite.

Owner:NORTHEASTERN UNIV

A kind of manufacturing method of tension screw type laminated iron core

ActiveCN107834786BNo loosenessReduce vibrationManufacturing stator/rotor bodiesPunchingElectric machine

The invention relates to a method for manufacturing a tension screw type laminated iron core, which comprises the following steps: step 1, stacking of punching sheets of the iron core and installationof tension screws: axially applying pressure on the punching sheets of the iron core by sections, and after the punching sheets of the iron core are stacked and pressed, preliminarily tightening fastening elements of the tension screws of the iron core in the compressed state; step 2, compaction processing: performing compaction processing on the iron core that is preliminarily tightened; step 3,when the iron core is at room temperature, tightening the tightening screws of the iron core subjected to compaction processing again; and step 4, spot welding for fixation: performing spot welding on the tension screws and the fastening elements thereof, so that the iron is fixed as one piece. Through the newly-added compaction processing, and re-tightening and then spot welding after the compaction processing, the iron core is formed as one piece to avoid the loosing of the laminated iron core loose, the laminated iron core is not easy to produce distortion and deformation, and ultimately the electrical performance of the motor is ensured and the working efficiency is improved.

Owner:湖南湘电动力有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com