Sewage treatment system

A sewage treatment system and technology of treatment system, applied in the field of sewage treatment system, can solve the problems of hardening passivation and reducing membrane flux, and achieve the effects of avoiding hardening and passivation, reducing the frequency of cleaning and replacement, and accelerating the absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described in detail below, but the protection scope of the present invention is not limited to the following description.

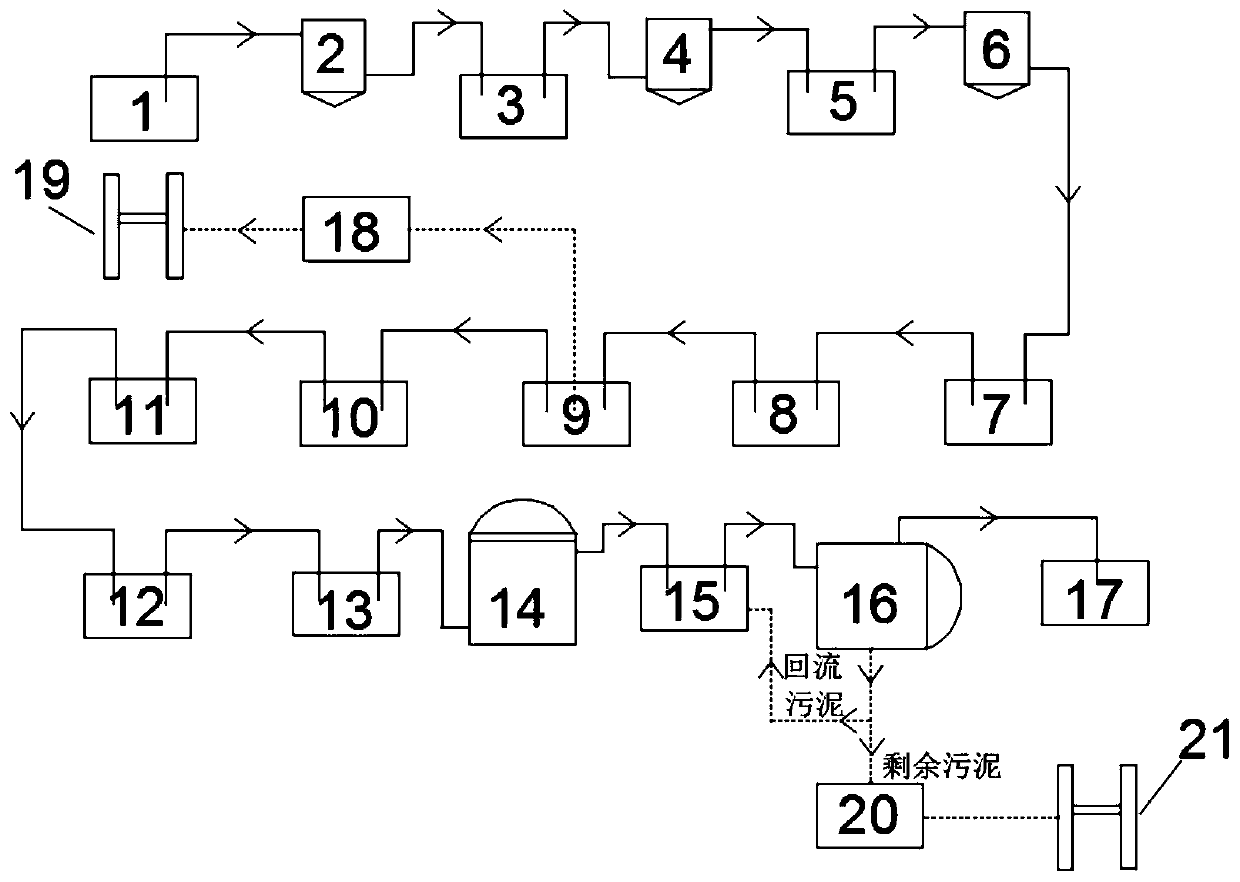

[0025] The sewage treatment system mainly includes a physical and chemical treatment system and a sewage advanced treatment system. The physical and chemical treatment system includes a waste emulsion treatment unit. The operating time of the emulsion treatment unit: continuous 8 hours / day, ≥300 days / year; the operating time of the advanced sewage treatment system: 24 hours / day, ≥330 days / year.

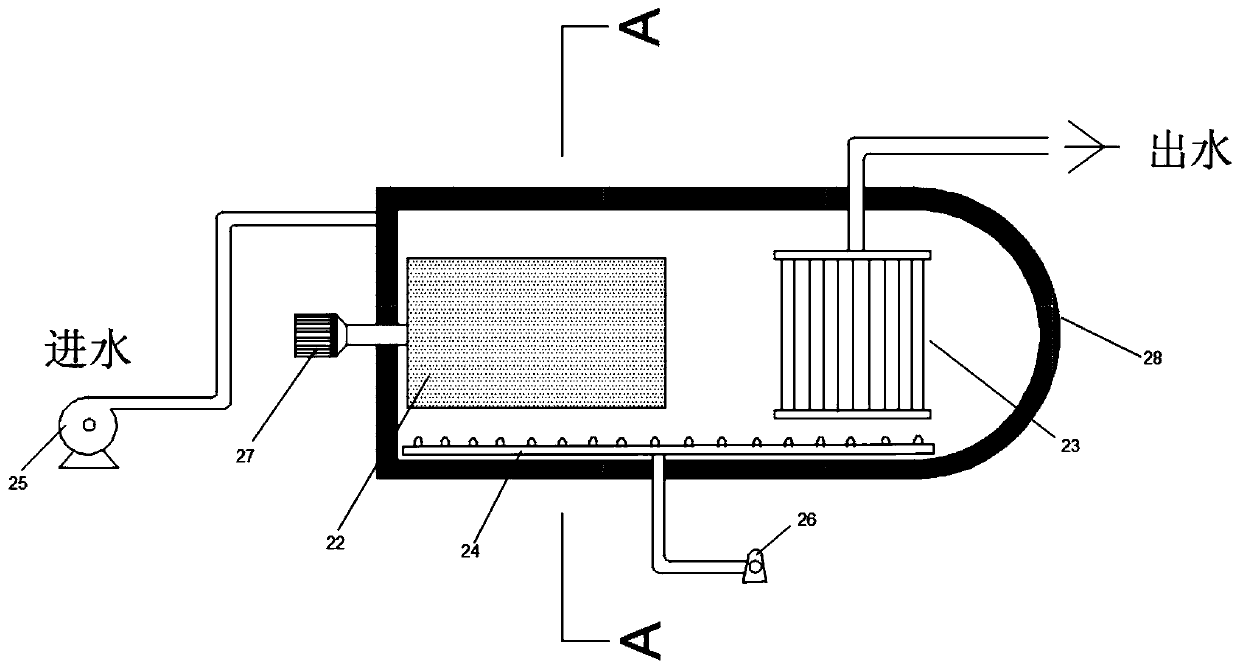

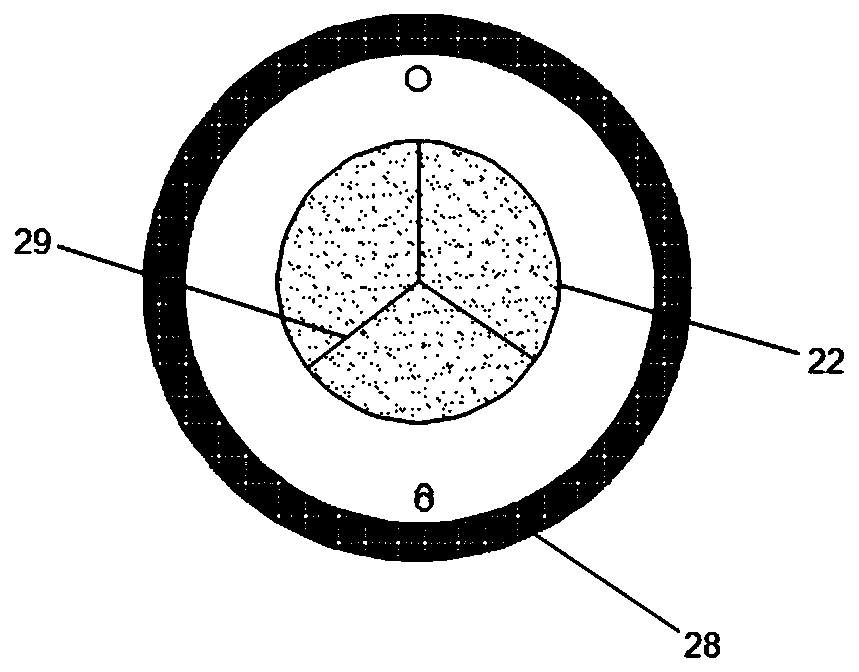

[0026] The physical and chemical treatment system includes sequentially connected filter tank 1, storage tank 2, grease trap 3, primary demulsification reaction tank 4, primary air flotation reaction tank 5, secondary demulsification reaction tank 6, and secondary air flotation reaction tank. Pool 7, Fenton reaction tank 8, flocculation sedimentation tank 9, intermediate detection tank 10 and emuls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com