A method of manufacturing a light-emitting diode epitaxial wafer

A technology for light-emitting diodes and a manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of reduction of production cycle and cost, inability to increase the growth rate of high-temperature buffer layer, etc., and achieve the effect of improving crystal quality and realizing growth cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

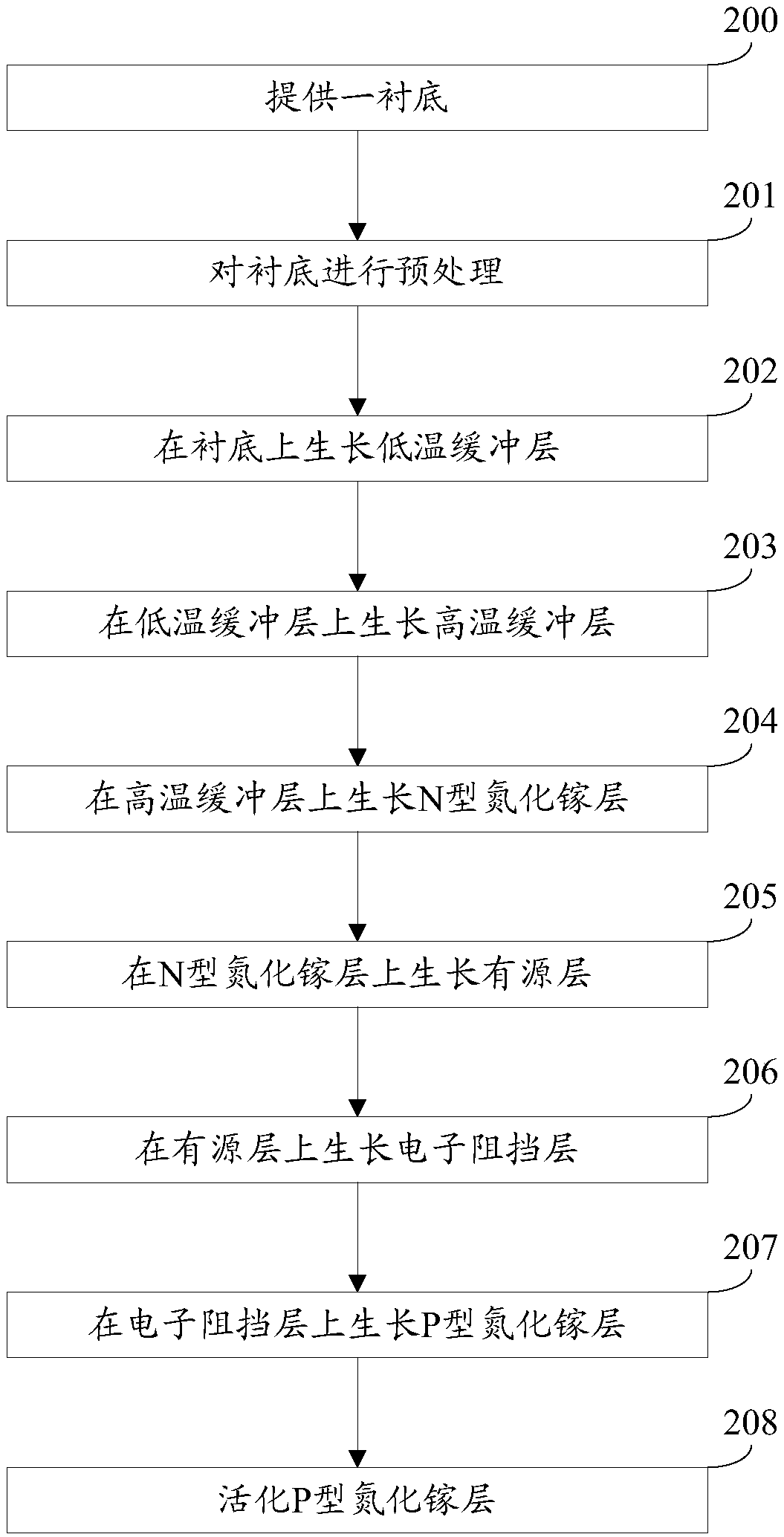

[0028] An embodiment of the present invention provides a method for manufacturing a light-emitting diode epitaxial wafer. In this embodiment, Veeco K465i or C4 metal organic compound chemical vapor deposition (English: Metal Organic Chemical VaporDeposition, referred to as: MOCVD) equipment is used to realize the LED epitaxial wafer. manufacturing. Using high-purity hydrogen (H 2 ) or high-purity nitrogen (N 2 ) or high purity H 2 and high purity N 2 The mixed gas as the carrier gas, high-purity NH 3 As nitrogen source, trimethylgallium (TMGa) and triethylgallium (TEGa) as gallium source, trimethylindium (TMIn) as indium source, trimethylaluminum (TMAl) as aluminum source, silane (SiH4) as N-type dopant, magnesium dicene (CP 2 Mg) as a P-type dopant. The pressure of the reaction chamber is controlled at 100-600 torr.

[0029] Specifically, see figure 1 , the growth method includes:

[0030] Step 200: Provide a substrate.

[0031] In this embodiment, the substrate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com