Method for preparing sintered ores by adding chromite into low-chromium vanadium titano-magnetite

A technology of vanadium-titanium magnetite and chromite, which is applied in the field of ironmaking raw materials, can solve the problems of sintered material particle size is easy to bond into large balls, sintered material layer has poor air permeability, and sintering process is easy to segregate, etc., to improve air permeability The effect of high temperature resistance and firing rate, good metallurgical properties, and high reflow temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

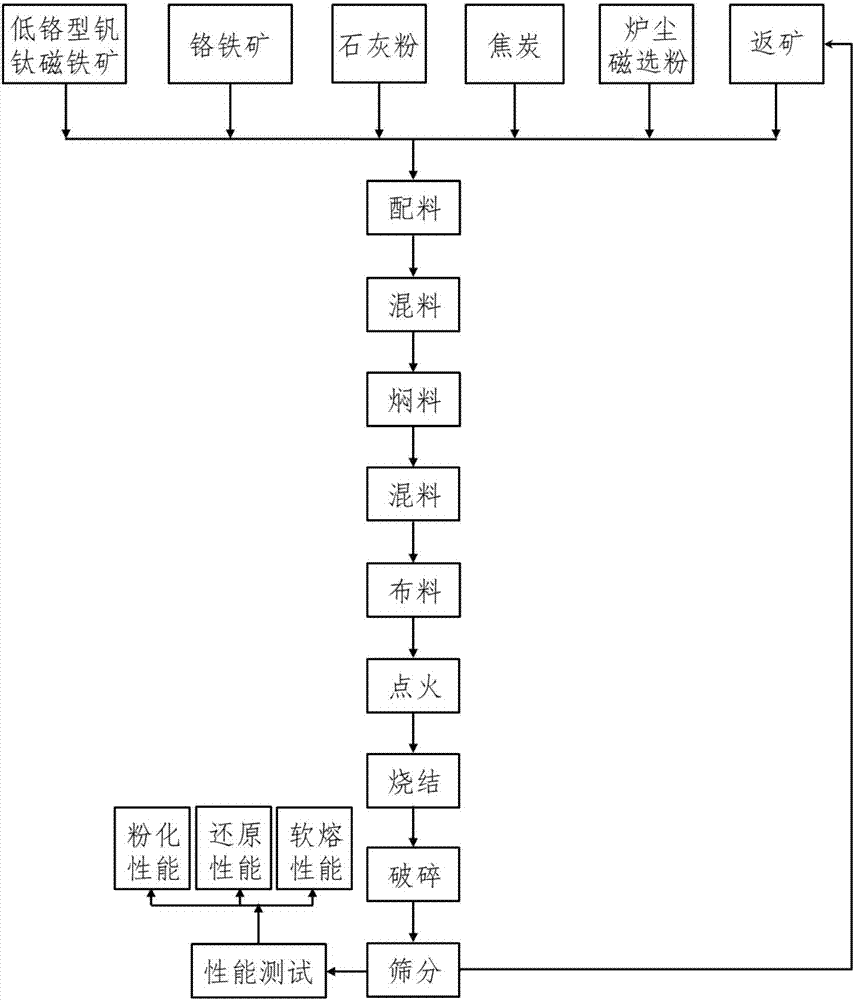

[0049] A method for preparing sintered ore by adding chromite to low-chromium vanadium-titanium magnetite, such as figure 1 As shown, the method includes the following steps:

[0050] 1. Mixing

[0051] The first stage: The sintering materials are 59.4kg of low-chromium vanadium-titanium magnetite from Honggebei Mine, 1kg of magnetic separation powder, 20kg of returned ore, 10.3kg of lime powder, 2.5kg of coke, and 2.5kg of coal powder. Weigh the raw materials according to the above batching, put them into the mixer for ore mixing, utilize a sprayer to spray mist water in the mixture during the mixing process, and the amount of sprayed water accounts for 5.5% of the total weight of the above raw materials. Time 8min;

[0052] The second stage: Cover the mixer and stew for 10 minutes. After the stew is over, continue to mix for 10 minutes.

[0053] 2. Granulation

[0054] Pour the mixed raw materials into the cylinder granulator to start granulation. During the granulation ...

Embodiment 2

[0070] A method for preparing sintered ore by adding chromite to low-chromium vanadium-titanium magnetite, the present embodiment is based on embodiment 1, and the specific operation steps are as follows:

[0071] 1. Mixing

[0072] The materials used for sintering are 59.2kg of low-chromium vanadium-titanium magnetite in Honggebei Mine, 10.6kg of chromite, 1kg of blast furnace dust, 1kg of magnetic separation powder, 20kg of returned ore, 10.3kg of lime powder, 2.5kg of coke, coal Powder 2.5kg. Weigh the raw materials according to the above ingredients, put them into the mixer for ore mixing, during the mixing process, spray mist water to account for 5.5% of the total weight of the raw materials, the mixing time is 12 minutes, and the mixer is covered and stewed for 10 minutes. Continue mixing for 12 minutes.

[0073] 2. Granulation

[0074] Pour the mixed raw materials into a cylinder granulator to start granulation. During the granulation process, spray mist water to acc...

Embodiment 3

[0090] This embodiment is on the basis of embodiment 1, concrete operation is as follows:

[0091] 1. Mixing

[0092] The sintering materials are 58.5kg of low-chromium vanadium-titanium magnetite in Honggebei Mine, 11.3kg of chromite, 1kg of blast furnace dust, 1kg of magnetic separation powder, 20kg of returned ore, 10.3kg of lime powder, 2.5kg of coke, coal Powder 2.5kg. Weigh the raw materials according to the above ingredients, put them into the mixer and mix them. During the mixing process, spray mist water to account for 5.4% of the total weight of the raw materials. The mixing time is 15 minutes, and the mixer is covered and stewed for 10 minutes. Continue mixing for 13 minutes.

[0093] 2. Granulation

[0094] Pour the mixed raw materials into a cylinder granulator to start granulation. During the granulation process, spray mist water to account for 0.7% of the total weight of raw materials, and granulate for 15 minutes.

[0095] 3. Discharge

[0096] After the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com